9 MAINTENANCE

en-57

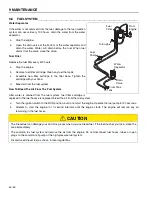

9.11 HYDRAULIC HOSES

______________________________________________________________

Always lower the cutting units to the ground, disengage all drives, engage parking brake, stop the engine and remove

the key before you inspect or disconnect hydraulic lines or hoses.

Check visible hoses and tubes each day. Look for wet hoses or oil marks. Replace worn or damaged hoses and tubes

before you operate the mower.

The replacement tube or hoses must be sent in the same path as the original hose. Do not move the clamps, brackets

and cable-ties to a new location.

Completely inspect all tubes, hoses and connections every 250 hours.

IMPORTANT: If the hydraulic fluid becomes dirty, damage to the hydraulic system can occur.

Before you

disconnect any hydraulic component, clean the area around the fittings and the ends of the hoses to prevent dirt to

enter the system.

Before you disconnect any hydraulic component, tag or mark the location of each hose then clean the area around the

fittings.

To prevent dirt to enter the hydraulic system when you disconnect the component, be prepared to assemble plugs or

caps to the ends of hoses and open ports. Clean any hydraulic fluid that spills.

Make sure “O” rings are clean and hose fittings are correctly installed before you tighten.

Prevent the hose to twist. The twisted hoses can cause the hose connections to loosen as the hose moves while you

operate the mower and can cause oil leaks.

The hydraulic hoses that are twisted or have sharp bends can decrease the oil flow and cause damage to the hoses.

The decreased oil flow can cause system problems and increase the temperature of the hydraulic fluid.

WARNING

To prevent injury from the hot, high pressure oil, never use your hands to check for oil leaks. Use the paper or

cardboard to find leaks.

The hydraulic fluid pressure can have enough force to enter your skin. If hydraulic fluid has entered your skin, a

doctor must remove the hydraulic fluid surgically within a few hours or gangrene can occur.

!

Summary of Contents for HR-9016 Turbo

Page 13: ...SPECIFICATIONS 4 en 12 K L D B A P P N C J H M E G...

Page 28: ...5 DECALS en 27...

Page 90: ...13 NOTES en 89 13Notes...

Page 91: ...NOTES 13 en 90...