MAINTENANCE 9

en-58

9.12 HYDRAULIC FLUID ________________________________________________________

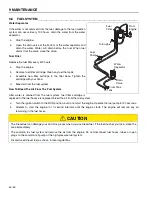

Drain and replace the hydraulic oil if one of the following occur.

•

Component failure

•

Water or foam is in the hydraulic fluid

•

The hydraulic fluid has a rancid odor (indication of high heat)

•

When service is indicated by filter service light, or each year, which is the first to occur.

Always replace the hydraulic filter when you replace the hydraulic fluid.

a

Clean the area around the oil cap and drain plug to prevent dirt to enter the hydraulic system.

b

Remove the drain plug from the bottom of the tank.

c

After the oil has drained, install the drain plug and fill the tank with hydraulic fluid.

d

Start the engine and remove the air from the hydraulic system. Operate all mower functions for 5 minutes to

remove the air and to balance the hydraulic fluid level.

e

When the oil-level has balanced and the air is removed, add fluid to the tank to the Full-mark on the dipstick

9.13 HYDRAULIC FILTER _______________________________________________________

The hydraulic system is protected by two 10 micron filters. The charge filter is found on the left side frame rail below the

radiator. The return filter is found on the left side of the hydraulic oil cooler.

Flow through the charge filter is monitored while you operate the mower. When the difference in hydraulic pressure

across the filter is greater than 16 to 20 psi (1.1 to 1.4 BAR), the charge filter warning light on the combination gauge

will illuminate. To make sure continued protection of the hydraulic system, replace the filter as soon as possible after

light illuminates.

When you replace the filters, -

a

Fill the new filter with hydraulic fluid and lubricate the filter O-ring with hydraulic fluid before you assemble the

new filter. Tighten the filter with your hand.

b

Operate the engine at idle speed for five minutes to remove the air from the hydraulic system. The oil-level light

can illuminate and the horn can activate during the five minutes.

c

Stop the engine and check the level of hydraulic fluid in the tank. Add the hydraulic fluid to the Full mark on the

dipstick.

NOTICE

During cold weather, the charge filter warning light can illuminate until the hydraulic fluid becomes warm. Wait until

the oil becomes warm and the warning light turn off before you operate the mower.

Summary of Contents for HR-9016 Turbo

Page 13: ...SPECIFICATIONS 4 en 12 K L D B A P P N C J H M E G...

Page 28: ...5 DECALS en 27...

Page 90: ...13 NOTES en 89 13Notes...

Page 91: ...NOTES 13 en 90...