9 ADJUSTMENTS

55

9.7

NEUTRAL ADJUSTMENT ___________________________________________________

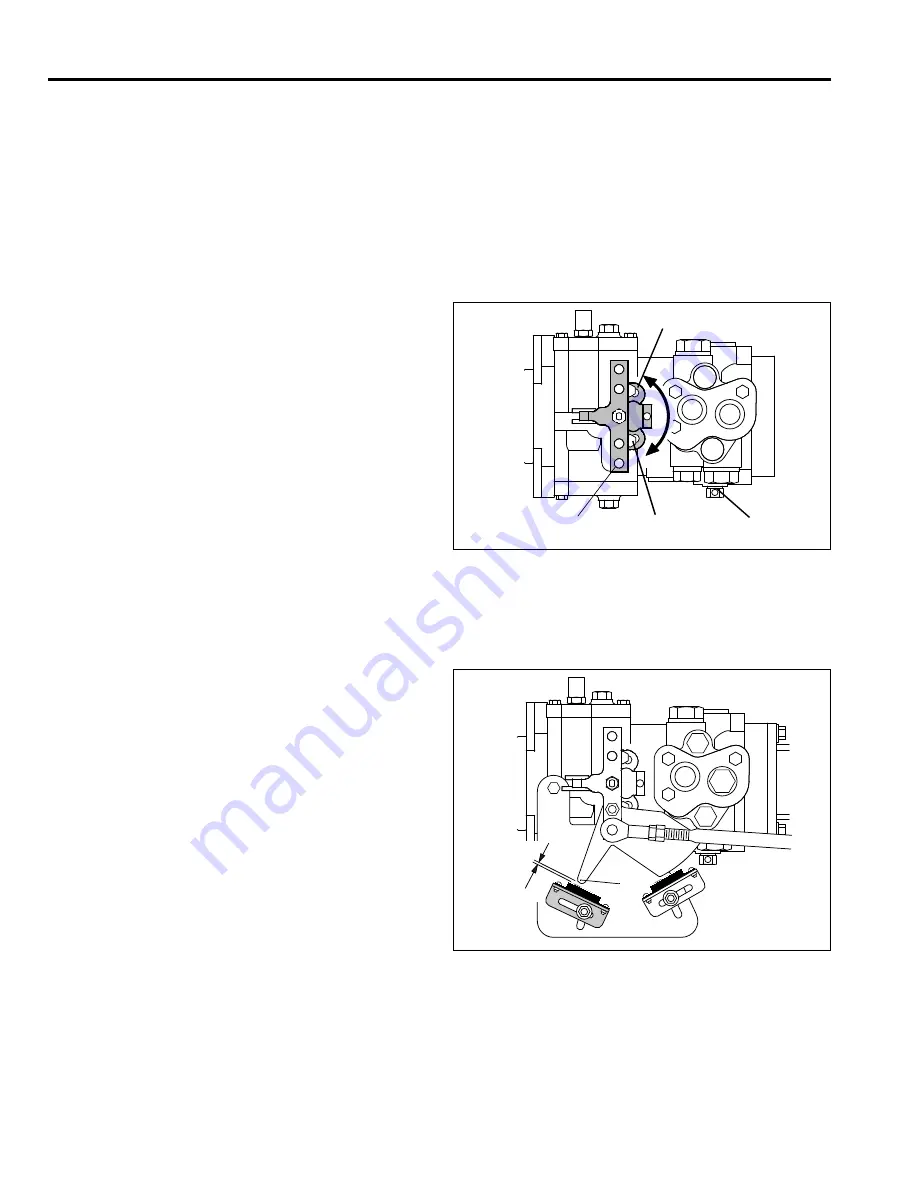

Important: The neutral adjustment on the drive pump is

preset at the factory on all new mowers and replacement

pumps. Further adjustment is required only if the pump

has been disassembled for service or neutral lever

bracket (F) has become loose.

To adjust neutral on pump:

1.

Disconnect traction pedal linkage from pump.

Remove switch mounting bracket from pump.

2.

Place mower securely on jack stands so All wheels

are raised off ground.

3.

Check that tow valve (H) is completely closed.

4.

Loosen screws (G) holding pump return arm bracket

just enough so it can be moved.

5.

Engage parking brake and set PTO switch to

neutral.

The neutral sensing switch must be closed in order to

start the mower. At this point the switch may not yet

be assembled to pump. To close switch so engine

can be started, place it face down on metal frame.

6.

Start engine and observe wheels. Rotate bracket (F)

in slotted holes until wheels do not turn. Turn OFF

engine and tighten bracket in place.

7.

Connect traction pedal linkage, Section 9.11, and

install and adjust switches, Sections 9.8 and 9.9.

Important: Always check operation of Interlock System

after replacing or adjusting switch. (See Safety and

Operation Manual)

8.

Start engine and check operation of traction pedal.

Wheels must not turn when pedal returns to Neutral.

Figure 9H

9.8

NEUTRAL SENSING SWITCH ________________________________________________

The neutral sensing switch is part of the operator backup

system. It is designed to prevent the mower from starting

unless the traction pedal is in Neutral. If this switch fails

or is out of adjustment, the mower will not start.

1.

Make sure drive pump and traction pedal linkage are

adjusted to neutral. Sections 9.6 and 9.11.

2.

Position switch so pointer (A) on activator plate is

centered over sensing area on switch.

3.

Adjust switch so gap between sensing surface on

switch and end of pointer is between 1/16 - 1/8 in.

(0.15 - 0.3 cm). Secure switch in this position.

Important: Always check operation of Interlock System

after replacing or adjusting switch. (See Safety and

Operation Manual)

Figure 9I

F

H

G

K

HR027

A

1/16” - 1/8”

(0.15 - 0.3 cm)

HR010

Summary of Contents for HR 9016 Turbo

Page 18: ...3 DECALS 17...

Page 53: ...ADJUSTMENTS 9 52 Figure 9D K J H G G...

Page 69: ...NOTES 12 68 12 NOTES...