11 QUALITY OF CUT

65

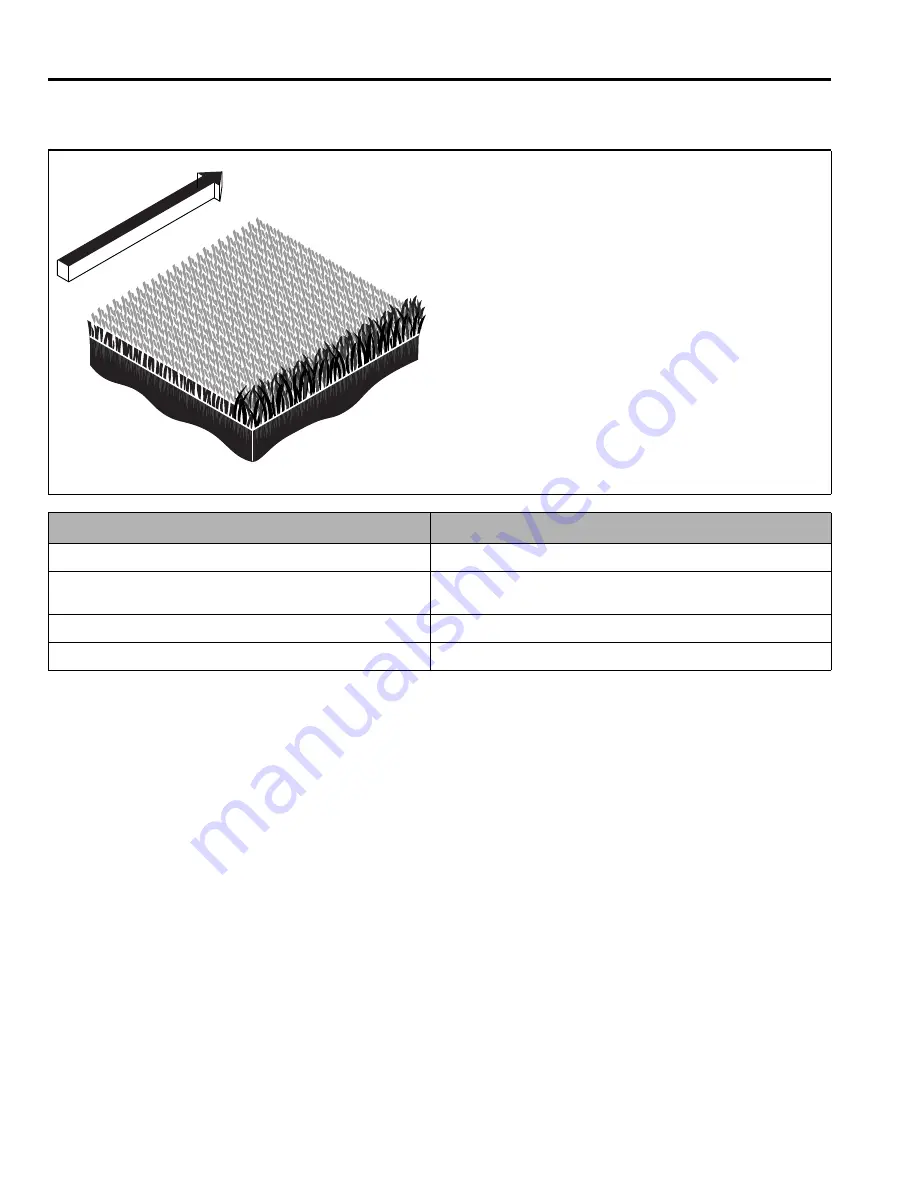

11.6 STREAKS ________________________________________________________________

NOTE: Arrow indicates direction of travel.

A streak is a line of uncut grass. This is usually caused by

a damaged blade.

Probable Cause

Remedy

Damaged blade(s).

Replace blade(s).

Turning too aggressively. Cutting units don’t overlap during turns

or on side hills.

Turn less aggressively to allow cutting units to overlap. Change

mowing direction or pattern on side hills.

Tire mats down grass before it is cut.

Check/adjust tire inflation pressure.

Wet grass is matted down before it is cut.

Cut when grass is dry.

TN0224

Summary of Contents for HR 9016 Turbo

Page 18: ...3 DECALS 17...

Page 53: ...ADJUSTMENTS 9 52 Figure 9D K J H G G...

Page 69: ...NOTES 12 68 12 NOTES...