SAFETY, OPERATORS & MAINTENANCE MANUAL

en-50

8

MAINTENANCE &

LUBRICATION

C

B

A

8.7

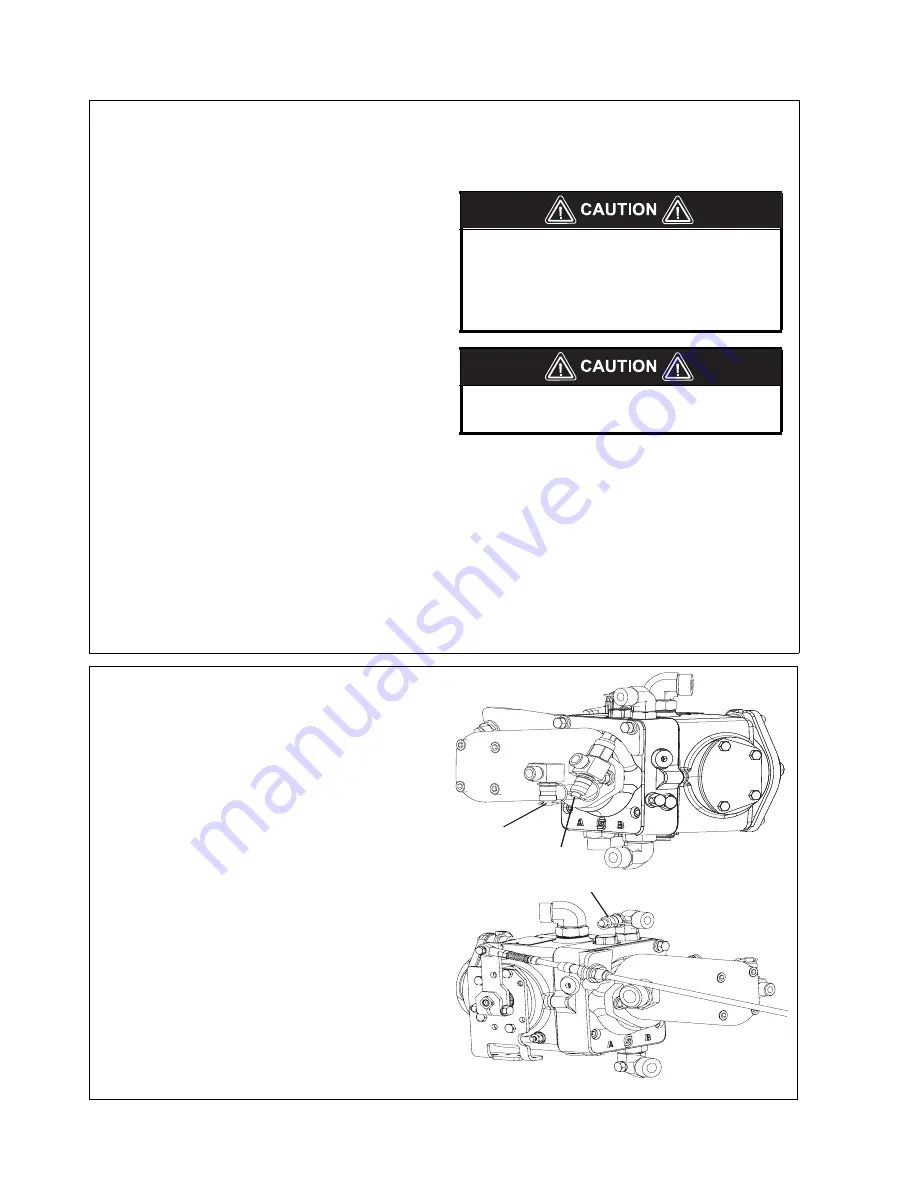

HYDRAULIC TEST PORTS

If any problems are experienced with the hydraulic

system service ports are provided to enable

pressures to be checked.

All tests, unless stated otherwise, should be carried

out with the hydraulic oil at normal working

temperature.

TEST PORTS

A.

Transmission pressure: 250 bar forward /

reverse.

B.

Deck drive pressure: 250 bar.

C.

Steering and lift pressure 125 bar.

NOTE: Any servicing of the hydraulic system must

be carried out by trained service personnel.

8.6

HYDRAULIC SYSTEM FLUSHING

When changing from mineral to vegetables oil

Terresolve ™ EnviroLogic ® BioFlush is a carefully

designed fluid which helps to flush and remove

petroleum oil from hydraulic systems. This is done

when converting hydraulic systems to the use of

biodegradable fluids.

EnviroLogic ® BioFlush will condition the internal

hydraulic system to help optimize both overall system

performance and fluid biodegradability.

1.

Run equipment until warm. Drain petroleum

hydraulic fluid and replace all hydraulic filters.

2.

Fill system with EnviroLogic. BioFlush. Run

equipment for 5 minutes until fluid is

completely circulated.

3.

Drain the BioFlush and replace hydraulic

filters.

4.

Fill system with approved biodegradable ISO

VG 46 hydraulic oil.

The hydraulic system is now optimized for fluid

biodegradability in the event of leakage.

When changing from vegetables to mineral oil

There is no need to flush the system.

Contact with hydraulic oil can

damage your skin. Use gloves when

working with hydraulic oil. If you

come in contact with hydraulic oil,

wash it off immediately.

Dispose of used hydraulic oil

in accordance with local regulations

Summary of Contents for HR3300T

Page 2: ...2011 Ransomes Jacobsen Limited All Rights Reserved...

Page 43: ...SAFETY OPERATORS MAINTENANCE MANUAL en 43 7 OPERATION...

Page 79: ...en 79 12 QUALITY OF CUT...

Page 84: ......

Page 85: ......