SAFETY, OPERATORS & MAINTENANCE MANUAL

en-57

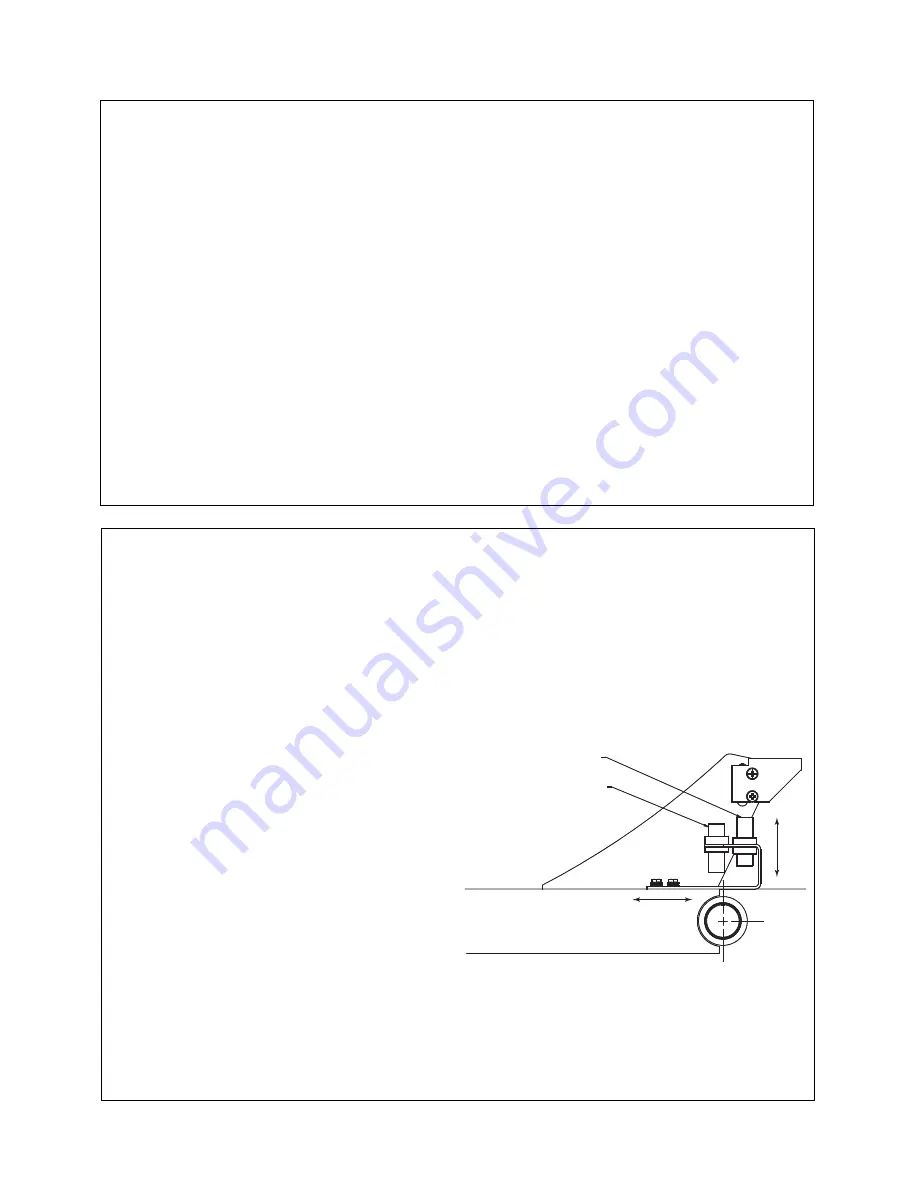

9

ADJUSTMENTS

B

C

A

E

D

Blades may be sharpened by filing or grinding. When

sharpening, maintain blade balance within 19.4 g/cm.

Failure to keep the blade balanced causes excess

vibration, blade wear and shortened blade life, and

may harm other mechanical components of the

machine as well.

To check blade balance

1.

Determine if there is a lighter end.

2.

Attach a 3.9g weight to the lighter end 127mm

from the centre of the blade.

3.

If the blade is adequately balanced, the weight

should convert the light end into the heaviest

end. If correction is required, file or grind the

heavy end to obtain balance.

NOTES:

•

Do not overheat or weaken blades when

sharpening.

•

Do not straighten bent blades.

*

If the lift portion of the blade is worn thin,

replace with a new blade.

•

Replace cracked or bent blades.

•

For greatest safety always use genuine

replacement blades.

9.6

LIFT ARM PROXIMITY SWITCH

Purpose

The magnetic proximity switch activates and

deactivates the cutting circuit.

Location

The magnetic proximity switch is located within the

front axle weldment above the right hand side lift arm

near to its pivot point.

Setting

In general do not adjust the position of the proximity

switch, only the magnets. Once factory set, the switch

should not require further adjustment.

If the magnetic proximity switch requires adjustment

only the magnets should be repositioned.

The magnet closest to the lift arm pivot controls the

lowering of the lift arm and the magnet closest to the

deck controls the raising of the lift arm.

Adjusting the magnet mounting bracket gives course

adjustment, fine adjustment is via the individual

magnet threads.

NOTE: Adjustment should only be undertaken using

the proximity switch test box Ransomes Jacobsen

part number 4168600.

Ensure that after any adjustment the blade drive

disengages when any part of the blade is raised above

400mm and does not restart until all parts of the blade

are below 400mm.

NOTE: If a magnet is lost from the bracket, the

proximity sensor will not be activated. The system is

designed to fail safe resulting in none activation of the

cutting circuit.

A.

Magnetic Proximity Switch

B.

Lower Magnet

C

Raise Magnet

D.

Course Adjustment

E.

Fine Adjustment

Summary of Contents for HR3300T

Page 2: ...2011 Ransomes Jacobsen Limited All Rights Reserved...

Page 43: ...SAFETY OPERATORS MAINTENANCE MANUAL en 43 7 OPERATION...

Page 79: ...en 79 12 QUALITY OF CUT...

Page 84: ......

Page 85: ......