GB-18

RANSOMES MASTIFF 91

SAFETY, OPERATORS, MAINTENANCE AND PARTS MANUAL

LUBRICATION

Read the safety instructions

Before using the machine for the first time lubricate

all points.

For recommended lubricants see page 12.

Should the number of working hours that the

machine is in use during the indicated period

exceed the number quoted in brackets, then use

the recommended ‘working hour’ guide as the

lubrication schedule.

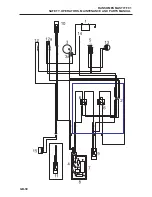

ENGINE (FIG. 15)

DAILY (EVERY 8 WORKING HOURS)

Clean the sump filler cap and surrounding area.

Check level of oil in the sump. Remove dipstick

plug (B) from either side of crankcase and check

that the oil is up to the correct level. Maximum oil

level (a): To top of filler hole threads. Minimum oil

level (b): To bottom of dipstick. Top up with

recommended oil if necessary.

FIRST 20 AND EVERY 100 WORKING

HOURS

DRAIN ENGINE OIL (FIG. 15)

(a).

After warming up the engine remove the

drain plug (A) and drain all oil from the

sump. Clean the plug and replace.

(b).

Refill the sump with the recommeded oil

through the dipstick/filler plug hole (B Fig.

15) up to the correct level. Capacity: 0.9

litres (1.6 lmp pints) 0.95 US Quarts.

(c).

Replace filler plug (B) after filling.

NOTE: Ensure machine is on level ground when

checking oil level.

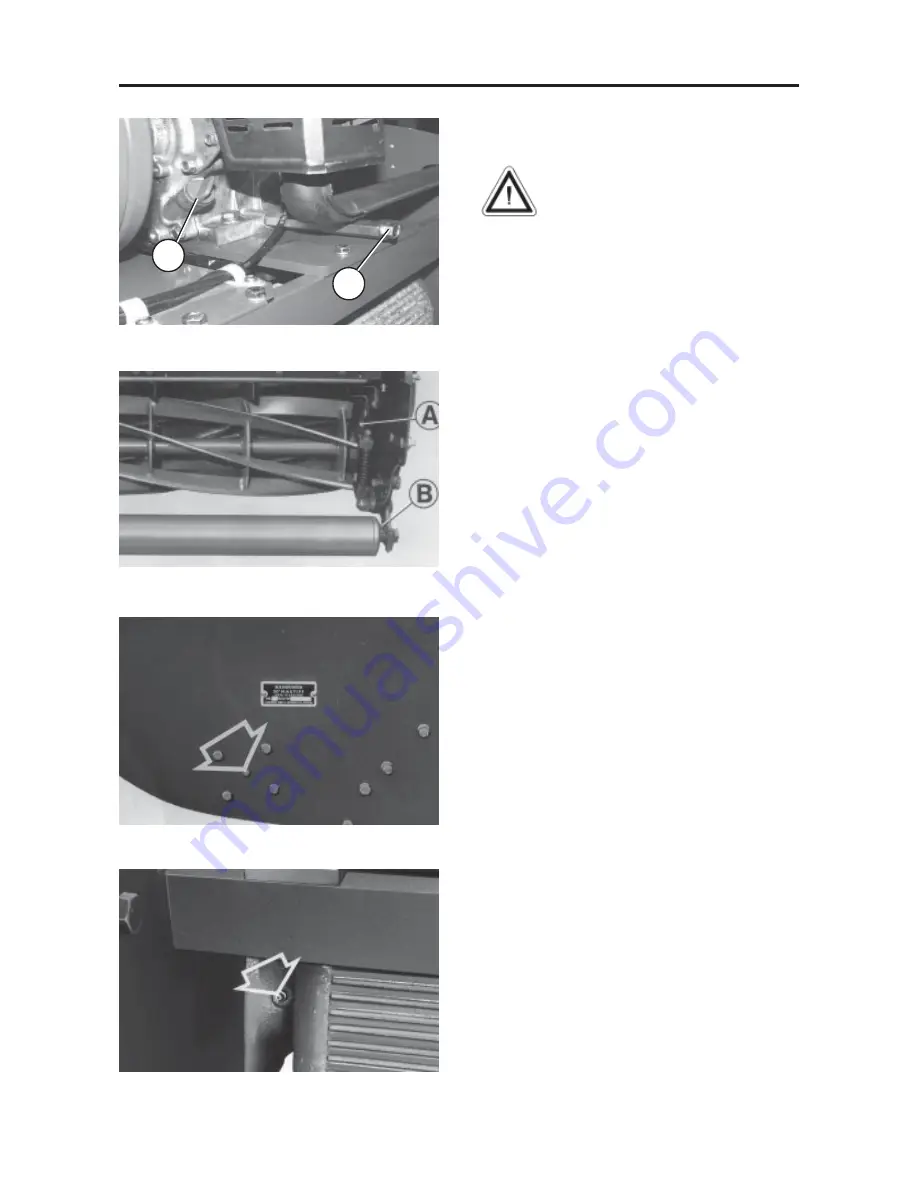

MACHINE

DAILY (EVERY 8 WORKING HOURS)

LUBRICATE THE FOLLOWING WITH

ENGINE OIL:

Cutting cylinder bearings

(A Fig. 16).

Front rolls , or side rolls, where fitted.

(B Fig. 16)

Landroll bearing housings

(Fig. 17 and 18).

Outer landrolls on 91cm (36in) machine.

Fig.16

Fig.17

Fig.18

Fig.15

A

B