6 MAINTENANCE & ADJUSTMENTS

GB-24

6

MAINTENANCE & ADJUSTMENTS

6.1 GENERAL ________________________________________________________________

Adjustment and maintenance should always be

performed by a qualified technician. If proper adjustment

cannot be made, contact an Authorized Jacobsen

Distributor. Refer to Section 6.2 for recommended

maintenance intervals.

1.

Inspect the equipment on a regular basis, establish a

maintenance schedule and keep detailed records.

• Keep the tractor and attachments clean.

• Keep all moving parts properly adjusted and lubri-

cated.

• Replace worn or damaged parts and decals before

operating the machine.

• Keep battery electrolyte at proper levels and bat-

tery connections clean.

• Keep shields in place and all hardware securely

fastened.

• Keep tires properly inflated.

2.

Do not wear jewelry or loose fitting clothing when

making adjustments or repairs.

3.

Use the illustrations in the Parts Catalog as

reference for the disassembly and reassembly of

components.

4.

Recycle or dispose of all hazardous materials

(batteries, lubricants, etc.) according to local, state

or federal regulations.

6.2

MAINTENANCE AND LUBRICATION SCHEDULE ________________________________

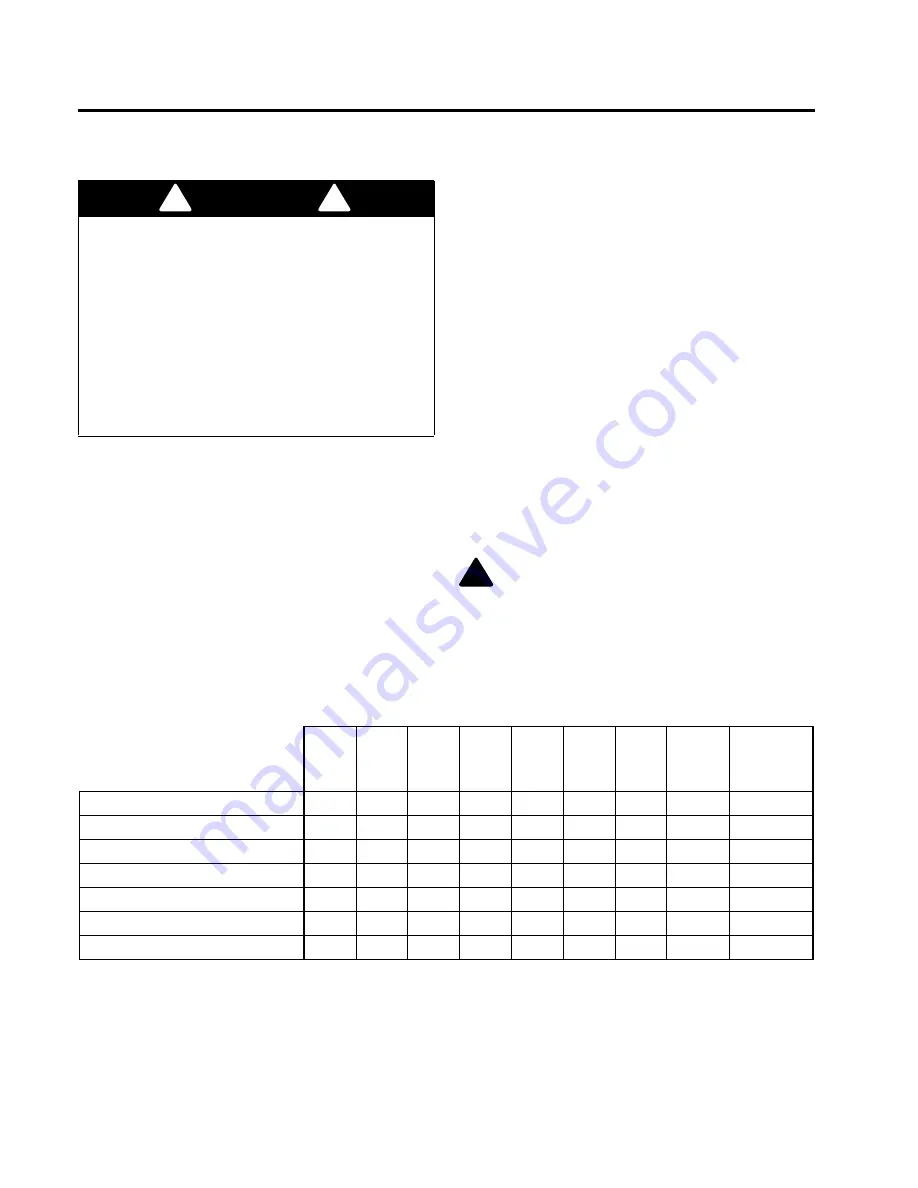

A - Add or Adjust C - Clean I - Inspect L- Lubricate R - Replace

I

Pack bearings with NLGI Grade 2 (Service Class GB)

II

Manual grease gun with NLGI Grade 2 (Service Class LB).

III

SAE 30W Heavy Duty Engine Oil

IV

Light lubricant

WARNING

To prevent injury, lower implements to the ground,

disengage all drives, engage parking brake, turn off

power, remove key from switch and disconnect power

connector before making any adjustments or

performing maintenance.

Make sure the tractor is parked on a solid and level

surface. Never work on a tractor that is supported

only by the jack. Always use jack stands.

If only the front or rear of the tractor is raised, place

chocks in front of and behind the wheels that are not

raised

!

!

CAUTION:

Be careful to prevent entrapment of

the hands and fingers between moving and fixed

components of the machine.

!

Recommended Inspection and Lubrication Intervals

Every

8

Hours

Every

25

Hours

Every

5

Hours

Every

100

Hours

Every

250

Hours

Every

500

Hours

Yearly

See

Section

Lubricant

Type

Batteries

C-I

5.4, 5.5

Parking Brakes

I-A

A

6.7

Grease Fittings

L

7.1

II

Steering Chain

I-L

7.1

IV

Tires

I-A

6.3

Wheel Bearings

A-L

I

Rear Axle

I

7.2

III