en-11

JACOBSEN TR3

SAFETY, OPERATORS & MAINTENANCE MANUAL

4.6

CUTTING UNIT SPECIFICATION

CUTTING UNIT LMAC194/195/196/197

CONSTRUCTION

Heavy duty welded pressed steel construction

REEL:

Diameter:

165mm

Width of cut:

660mm

Number of knives: 7 and 11

Height of cut:

12mm - 47mm

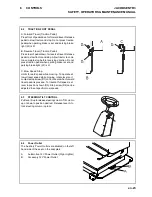

REEL TO BEDKNIFE ADJUSTMENT

Self locking notched hand micro adjusters. Each

notch giving 0.04mm (0.0015in) of movement.

HEIGHT OF CUT ADJUSTMENT

Front roll:Threaded roll carriage & locknuts.

Rear roll:

Coarse adjustment:Three position housing

mounting.

Fine adjustment: Threaded roll carriage &

locknuts

REAR ROLL

Full width 75mm (3in) diameter plain roll running on

taper roller bearings with shaft seals and lubricators.

FRONT ROLL

Full width 75mm (3in) diameter grooved roll running

on taper roller bearings with shaft seals and

lubricators.

or

Full width 75mm (3in) diameter plain roll running on

taper roller bearings with shaft seals and lubricators.

4.7

RECOMMENDED LUBRICANTS

Engine oil:

Should be to MIL-L-2104C or to

A.P.I. Classification CD grades.

[10W-30]

Hydraulic Oil:

Greenscare 46 (ISO 46) Bio

Degradable Oil

Grease:

Shell Darina R2, or equivalent.

4

SPECIFICATIONS

BEDKNIFE BACKING & BEDKNIFE

Blade replaceable, mounted onto welded steel

constructed bedknife backing.

TRANSMISSION

By hydraulic motor through cardan shaft to cutting

cylinder.

CUTTING UNIT 47114, 47115, 47116

CONSTRUCTION

Heavy duty welded pressed steel construction

REEL:

Diameter:

178mm

Width of cut:

660mm

Number of knives: 7

Height of cut:

9.5mm - 69.8mm

Bearings Self-adjusting tapered roller bearings

Rollers

Grooved Front (Nylon) - 26 in., (660 mm)

Grooved Front (Steel) - 26 in., (660 mm)

Solid -

26 in., (660 mm)

4.8

CUTTING PERFORMANCE (AREA)

1.58 hectares/hr. at 9.6 km/hr. ( 3.9 acres/hr at 6.0

mph)

10% allowance is included for normal overlaps and

turning at the end of each cut.

Cutting Frequency

(7-blade) 7.4 mm/1,6 Km/h

T E M P E R AT U R E

V IS C O S IT YI

A B OV E 2 5 °C (7 7 °F )

S A E 3 0

o r

S A E 1 0 W -3 0

S A E 1 0 W -4 0

0 °C to 2 5 °C (3 2 °F to 7 7 °F )

S A E 2 0

o r

S A E 1 0 W -3 0

S A E 1 0 W -4 0

B E L O W 0 °C (3 2 °F )

S A E 1 0 W

o r

S A E 1 0 W -3 0

S A E 1 0 W -4 0

Summary of Contents for TR3 EJ Series

Page 2: ...2010 Ransomes Jacobsen Limited All Rights Reserved...

Page 33: ...en 33 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 7 OPERATION...

Page 35: ...en 35 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 8 MAINTENANCE LUBRICATION...

Page 73: ...en 73 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 11 TROUBLESHOOTING...

Page 74: ...en 74 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 12 1 HYDRAULIC CIRCUIT 12 SCHEMATICS...

Page 84: ......

Page 85: ......