en-40

JACOBSEN TR3

SAFETY, OPERATORS & MAINTENANCE MANUAL

8.7

HYDRAULIC SYSTEM

Check Hydraulic Oil Level

Check hydraulic oil level using dipstick

attached to the filler cap (B). The correct

level is between the two markers (C).

Change Hydraulic Oil

(a)

Remove drain plug from bottom of

Hydraulic tank and wipe off plug. (A)

(b)

Allow tank to drain and replace plug.

(c)

Refill tank with the correct quantity and

grade of Hydraulic Oil through the filler cap.

(B) .

IMPORTANT-Whenever the closed loop

transmission circuit has been broken into,

it is essential that the circuit is flushed prior

to use. Absolute cleanliness must be

observed when filling the hydraulic tank.

Oil must be filtered through a 25 micron

filter before entering the hydraulic tank.

8

MAINTENANCE & LUBRICATION

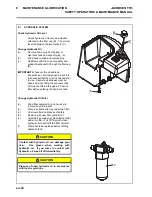

Change Hydraulic Oil Filter

(a)

Wipe filter canister (A) and housing to

remove any dirt present.

(b)

Place a suitable drip tray under the filter.

(c)

Unscrew filter and dispose of safely.

(d)

Replace with new filter canister (A).

(e)

Coat the top outside lip of the filter canister

with a thin film of oil, fill filter with clean

hydraulic fluid and refit the filter canister.

(f)

Filter should be replaced before refilling

hydraulic tank.

CAUTION

Contact with hydraulic oil can damage your

skin. Use gloves when working with

hydraulic oil. If you come in contact with

hydraulic oil, wash it off immediately.

CAUTION

Dispose of used hydraulic oil in accordance

with local regulations.

Summary of Contents for TR3 EJ Series

Page 2: ...2010 Ransomes Jacobsen Limited All Rights Reserved...

Page 33: ...en 33 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 7 OPERATION...

Page 35: ...en 35 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 8 MAINTENANCE LUBRICATION...

Page 73: ...en 73 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 11 TROUBLESHOOTING...

Page 74: ...en 74 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 12 1 HYDRAULIC CIRCUIT 12 SCHEMATICS...

Page 84: ......

Page 85: ......