en-46

JACOBSEN TR3

SAFETY, OPERATORS & MAINTENANCE MANUAL

CUTTING UNITS LMAC194 / 195 / 196 / 197

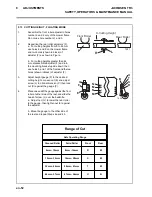

9.3

HEIGHT OF CUT

It is important to set the rear roll parallel to the

bedknife in order to achieve the minimum height of

cut setting for the three ranges of height, in the three

sets of mounting housing (D) bolt holes. Positions

'A','B' &'C'.

Setting the minimum height with the mounting

housings (D) in position 'A' will allow minimum height

and parallelism to be achieved in each of the other

two positions 'B' & 'C'.

Once the range has been chosen the actual height

of cut is set by adjusting the front roll only by carriage

screws (F) and locknuts (J).

9.4

TO SET REAR ROLL

with a new bedknife

1.

Set the height of cut setting bar (G)as follows:

a. Screw X to 12mm(15/32in) under the head.

b. Screw Y to 6.5mm (1/4in) to screw thread

tip.

Note: The difference between screw X and screw Y

is 5.5mm (7/32in).

2.

Set roll carriage mounting housing(D) bolts

into holes 'A'.

3.

Place the setting bar (G)as shown at one end

of the bottom blade with the screw head X over

the lip and screw thread Y tip against base of

blade.

4.

Adjust the roll to the setting bar (G) with the

two locknuts(H) holding setting bar screws

in contact.

5.

Repeat for other end of bedknife.

9.5

TO SET HEIGHT OF CUT

Chose the range of height in which cutting is to be

carried out and then adjust front roll only.

1.

Preset the height of cut setting bar (G)as

follows:

a. Screw X to the required height of cut under

the head.

b. Screw Y is not used.

2.

At one end of the bedknife lay setting bar (G)

on rear roll with screw head over bedknife lip.

3.

Adjust front roll to the setting bar by means of

the two front locknuts (J).

4.

Repeat for the other end of the bedknife.

9

ADJUSTMENTS

Height of Cut

Range

Minimum

Height of Cut

Maximum

Height of Cut

Holes 'A'

12.0mm

19.0mm

Holes 'B'

19.0mm

35.0mm

Holes 'C'

27.0mm

47.0mm

CAUTION

The height of cut range for each set of holes

takes into account the requirement of the

cutting unit to float. Increasing the maximum

height of cut in any of the hole setting ranges

could restrict the ability of the cutting unit to

float.

Summary of Contents for TR3 EJ Series

Page 2: ...2010 Ransomes Jacobsen Limited All Rights Reserved...

Page 33: ...en 33 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 7 OPERATION...

Page 35: ...en 35 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 8 MAINTENANCE LUBRICATION...

Page 73: ...en 73 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 11 TROUBLESHOOTING...

Page 74: ...en 74 JACOBSEN TR3 SAFETY OPERATORS MAINTENANCE MANUAL 12 1 HYDRAULIC CIRCUIT 12 SCHEMATICS...

Page 84: ......

Page 85: ......