34

MAINTENANCE

Read all of SAFETY and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

Owner’s Guide

LIGHT BULB REPLACEMENT

To decrease the risk of premature bulb failure, do not allow your fingers to contact new bulbs. Use clean, dry

paper or paper towels to touch the glass part of the bulb.

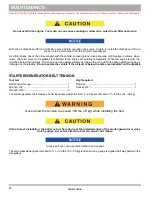

Headlight

To prevent the bulb from accidentally disconnect-

ing and possibly melting or igniting plastic compo-

nents, the locking ring MUST be installed again

after installation of replacement bulb.

Rotate the bulb socket a quarter turn to the left to unlock.

Remove the bulb and socket. Install new bulb and rotate

the socket a quarter turn to the right to secure.

Replacement bulbs are available from a local Distributor, an authorized Branch or the Service Parts Department.

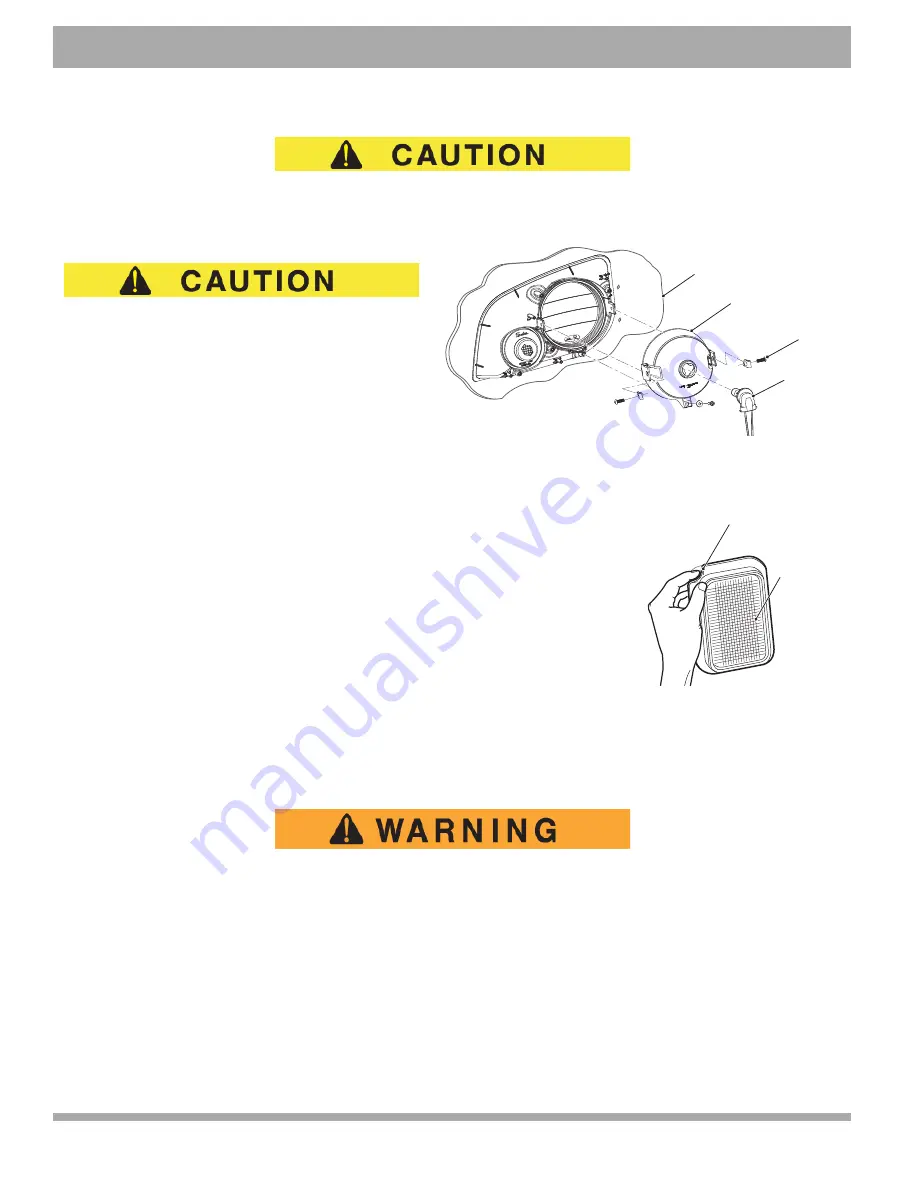

Taillight

To replace the taillight and brake light bulb, roll the rubber bezel from around the edge of

the taillight and remove the lens. Install the replacement bulb and replace the lens.

FUSE REPLACEMENT

The fuse block is below the driver seat. Lift the seat bottom to access the fuses.

Remove the old fuse and replace with a new fuse of the same type and size.

Fuses are available from a local Distributor, an authorized Branch or the Service Parts Department.

VEHICLE WITH A DISCHARGED BATTERY

To decrease the risk of severe injury or death from accidental movement, do not use a jumper

cable to start a vehicle.

The vehicle has a starter/generator and does not idle. When you start the engine, the starter/generator functions as a

starter and with the engine running, it functions as a generator.

The generator can keep the battery charged with the short run times with this type of vehicle. The generator will not

charge a discharged battery.

When the engine starts, the clutches engage and cause the vehicle to move making ‘jump starting’ both dangerous and

impractical.

If the battery has discharged, charge it with a 12-volt charger that is rated at 10 amps or less and according to instruc-

tions supplied by the manufacturer of the charger.

Inside of Cowl

Headlight

Casing

Screw

Headlight

Bulb

Tail/Brake

Light

Roll Rubber

Bezel Away

From Body