10

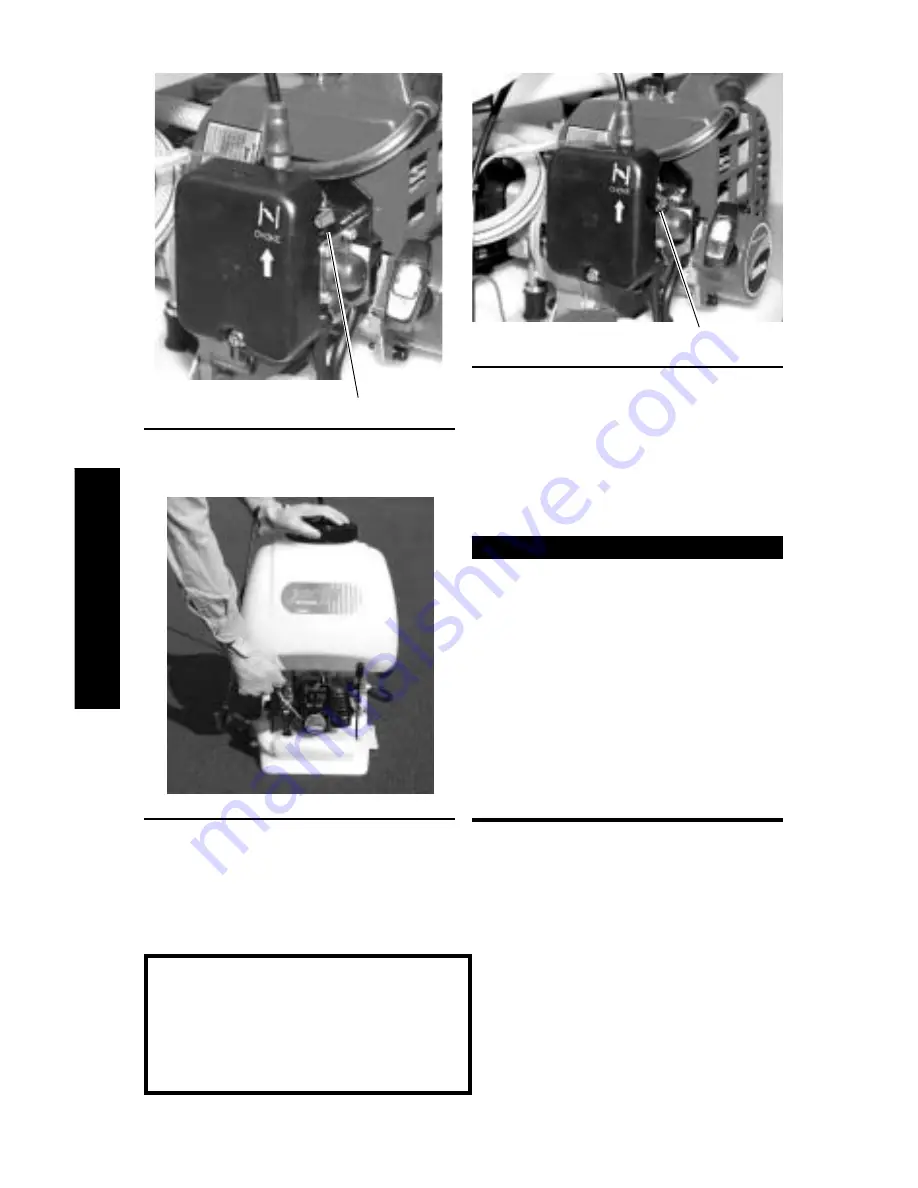

Figure 12

7. Set the choke lever to the closed

position. See figure 12.

Figure 13

8. Hold the HP726 firmly with one

hand. Slowly pull the recoil starter

handle until resistance is felt, then

pull quickly to start the engine.

See figure 13.

Starting the Engine (Cont.)

CAUTION!

Do not pull the recoil starter to the

end of the rope travel. Pulling the

recoil starter to the end of the rope

travel can damage the starter.

9. When the engine starts, slowly

move the choke lever to the

"OPEN" position. If the engine

stops after the initial start, close the

choke and restart. See figure 14.

IMPORTANT!

If the engine fails to start after

several attempts with the choke in

the closed position, the engine may

be flooded with fuel. If flooding is

suspected, move the choke lever to

the open position and repeatedly pull

the recoil starter to remove excess

fuel and start the engine.

If the engine still fails to start, refer to

the troubleshooting section of this

manual.

Figure 14

Choke Closed

Choke Open

OPERATION

Summary of Contents for HP726

Page 29: ...28 Notes...