26

3. Check the voltage at the transformer secondary. See section A15, page 57, for transformer testing instruc-

tions. If the voltage is bad, replace the transformer. If the voltage is good, proceed to step 4.

4. Check the circuit board transformer connections. If the connections are loose or oxidized, repair the connec-

tions and retest the system. If the problem persists, replace the circuit board.

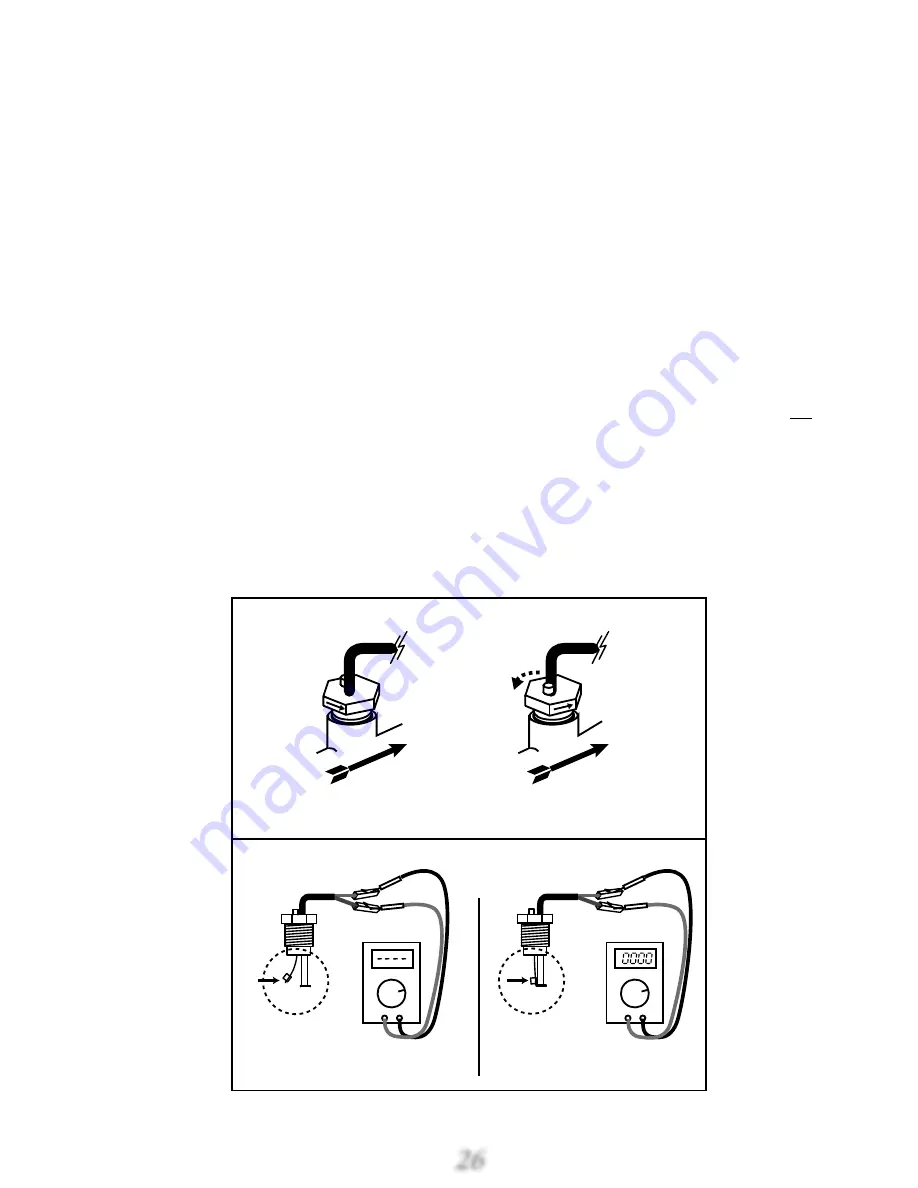

.4 Testing Flow Switch

1. Verify the flow switch directional arrow is pointing in the direction of flow awary from heater and towards

the heater return fitting outlet. If the flow switch orientation is incorrect, loosen or tighten the switch no

more than 1/2 turn, being careful not to bottom out the switch in the fitting. The switch’s flow arrow must

be parallel to the tee fitting as shown (fig. A). Test the system operation. If the condition persists, proceed to

step 2.

2. Remove the switch from the fitting making note of the number of turns (revolutions) it takes to do so. Visu-

ally inspect the switch for debris interference or damage. If debris is present, remove the debris, then reinstall

the switch with the same number of turns as originally installed. Test the system. If the switch is damaged,

replace the switch and retest the system. If the condition persists, proceed to step 3.

3. Test the switch operation with an ohmmeter (set to 1000-2000k range) for continuity across the switch ter-

minals. Measure resistance across the switch terminals for infinite resistance with the magnet arm

not

touch-

ing the switch body (fig. B), and for continuity (Ø ohms) with the magnet arm touching the switch body (fig.

B). If the flow switch tests OK, check the wiring harness. If the wiring harness tests OK, replace the circuit

board.

fig. A

fig. B

Incorrect

Orientation

Correct

Orientation

FLOW

Arrows

aligned

FLOW

Arrows

not

aligned

Open

Continuity 0

Ω

(Pump ON)

Closed

Ω

Infinite

Ω

(Pump OFF)

Ω

Summary of Contents for Premium J-315

Page 45: ...45 Appendix...

Page 62: ...62 Notes...