Tool change

Item no. 10205032, Revision 00

25 ( 36 )

10

Tool change

CAUTION: Danger of being drawn in by rotating shaft.

If the shaft is still rotating, fingers and hands may be drawn in and crushed.

u

Only change the tool if the shaft is at a standstill.

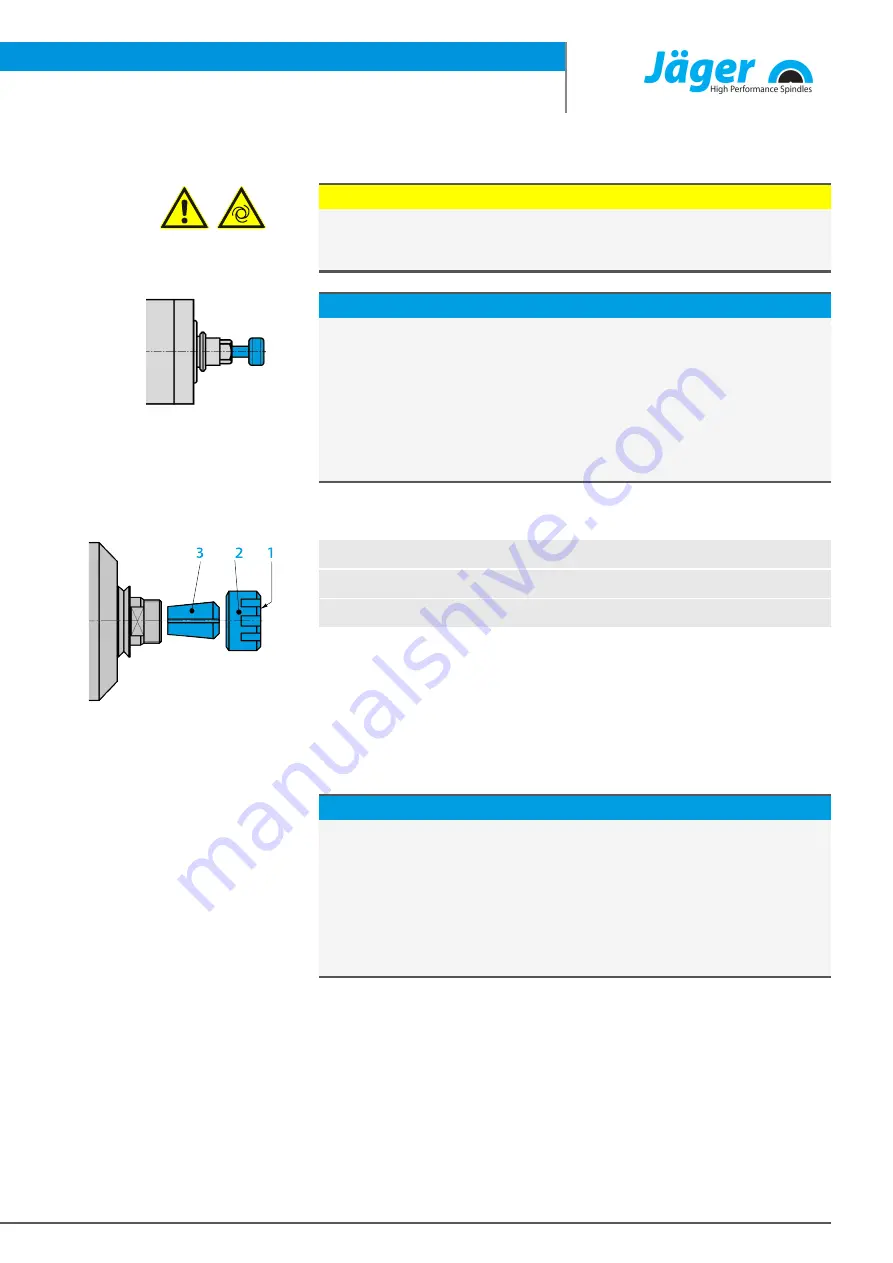

Example of design: Inserting the

shank

Note: Ensure functionality.

u

Never operate the HF spindle without a clamped tool shank.

If no tool shank is clamped:

q

The clamping system is damaged by the centrifugal forces.

q

The clamping system is shifted.

q

The balance of the HF spindle is affected.

q

The bearing is damaged.

10.1

manual tool change

1

End face

2

Clamping nut

3

Collet (optional accessory)

Proceed as follows to change the tool:

Ü

Screw the clamping nut out.

Ä

The collet is also pulled out in the process.

Ü

Remove the tool.

Ü

Remove the collet from the clamping nut.

Note: Ensure functionality.

All contamination damages the collet, clamping nut, tool mount, etc. As a re-

sult, the function of the HF spindle is no longer guaranteed.

u

Clean the collet.

u

Clean the clamping nut.

u

Clean the thread of the shaft.

u

Clean the inner taper of the shaft.

Ü

Lightly grease the thread of the clamping nut.

Ü

Push the collet into the clamping nut until it engages in the groove pro-

vided for this purpose.

The collet is inserted correctly when it is flush with the end face of the clamp-

ing nut. This is the only way in which to guarantee that the collet is also pulled

out when the clamping nut is loosened.

Ü

Insert the tool.

Ü

Make sure that the shank of the clamped tool does not press on the inner

stop of the tool mount once the clamping nut has been tightened.