Specifications

Dimensions

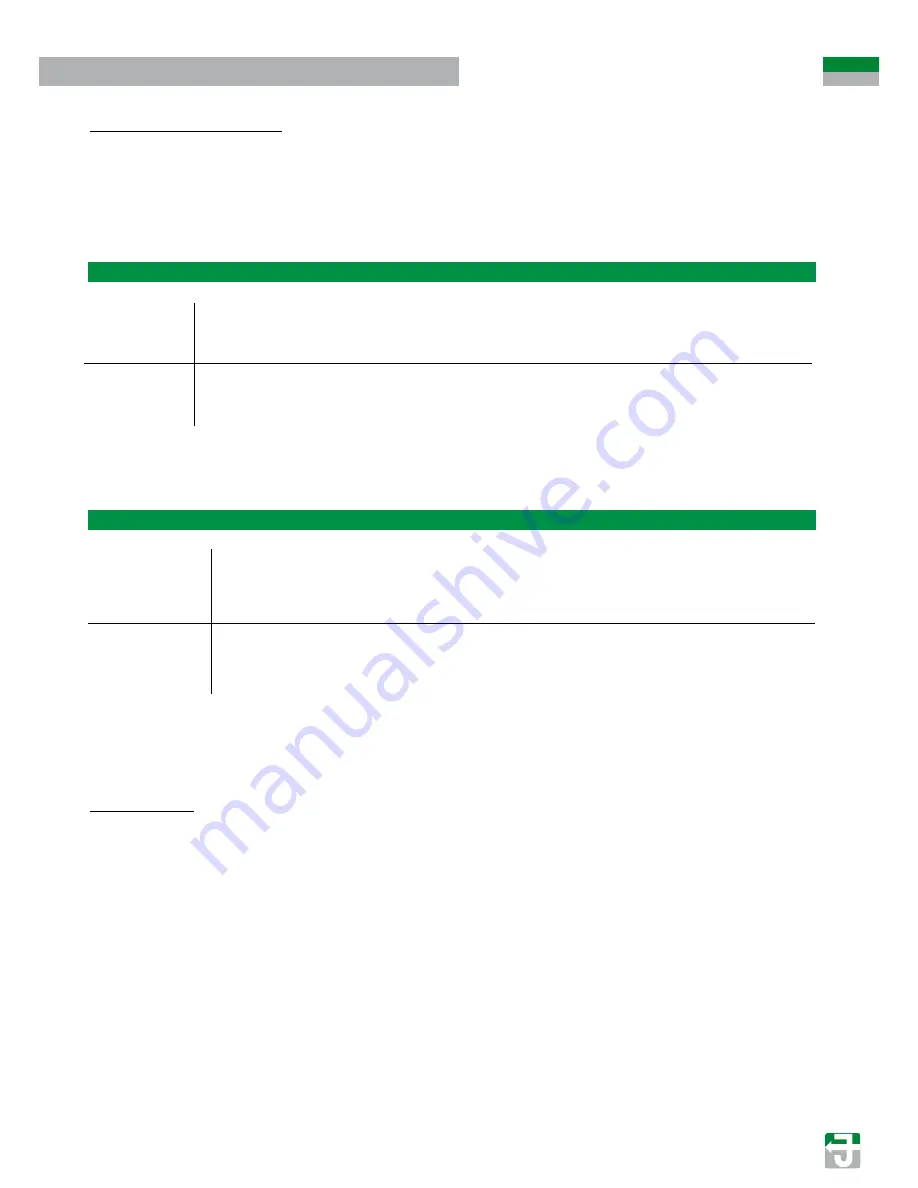

Dimensions for threads and double nipple:

Type

63/2100 D

63/2075 D

63/2050 D

Connector

1” Whitworth

3/4” Whitworth

3/4” NPT

Perforation

length

[mm]

1000

750

500

Double nipple length

square tube

100 x 100 mm

[mm]

150

150

-

Double nipple length

square tube

80 x 80 mm

[mm]

130

130

-

Double nipple length

tube DN100

(114,3 mm)

[mm]

190

-

-

Colour

code

blue

green

grey

Total length*

[mm]

1060

810

560

Tube

diameter

[mm]

63

63

63

ID-Sleeve**

[mm]

64 - 66

64 - 66

64 - 66

Perforated area

[m

2

]

0,18

0,135

0,09

*Other lengths on request.

** Exact diameter acc. to customer specification.

3/4” NPT-joint: maximal diffuser length 610 mm, diffuser will be connected to 3/4” NPT weld-on threaded nip-

ple. Double nipples for other tube dimensions on request.

1. Aeration System

This manual gives a detailed description of installation

and operating of the tube diffuser JetFlex TD 63 /2 with

the perforation lengths 1000 mm, 750 mm and 500 mm

(39.4“, 29.5”, 19.7”).

2. General

Gummi-Jaeger GmbH Aeration Components delivers aerating systems for applications in aeration

basins in communal and industrial waste water treatment plants.

The aerating systems are intended for fine-bubble compressed air ventilation of activated sludge in

biological waste water treatment. With membranes made of EPDM-rubber an intermittent operation

is possible due to the long-term elasticity of the membrane material.

For applications in industrial waste water treatment plants and/or in communal plants along with more

than 10% industry share please consult Gummi-Jaeger regarding suitability of membrane materials.

Quality properties of materials, perforation and bubble size/uniformity are controlled and recorded

generally.

The aeration systems are delivered completely assembled. Gummi-Jaeger GmbH Aeration Components

recommends a careful treatment of storage, transport and installation, to avoid damage of the mem-

branes.

The Gummi-Jaeger GmbH General Conditions of Sale are valid in their new version, respectively.