Specifications

6. Assembly

6.1 Preparations

• Prior to assembly of the aeration systems pipings and basins have to be cleaned of all pollutions

like stones, wood pieces, etc.

• As lateral should be used high-grade stainless steel square tubes with dimensions of

80 x 80 mm or 100 x 100 mm.

• Using standard PVC (Schedule 40 or 80) or stainless steel pipes DN 100 (114.3 mm / 4.5”) as

laterals special round tube adapters are necessary .

• Air distribution through JetFlex TD 63/2 tube diffuser is a function of individual diffuser elevation.

For proper system operation all lateral pipes must be levelled within a tolerance of ± 0,6

cm / ± 1/4”.

• The use of 1“ double nipples requires a lateral piping with predrilled and tapped outlets with a

diameter of 34

mm / 1.34” aligning on horizontal axis with a tolerance of ± 0.5 mm / ± 0.02”.

• The use of 3/4” double nipples requires predrilled and tapped outlets with a diameter of 27

mm

/ 1.06” aligning on horizontal axis with a tolerance of ± 0.5 mm / ± 0.02”.

• Outlet holes may not lie in the weld area.

• Contractor is to confirm the cleanliness of the air piping. Corrosion damages (rust) are to be

eliminated. Air purge or water flush cleaning is recommended prior to diffuser installation to

remove any internal debris and tailings that may have accumulated in the header piping.

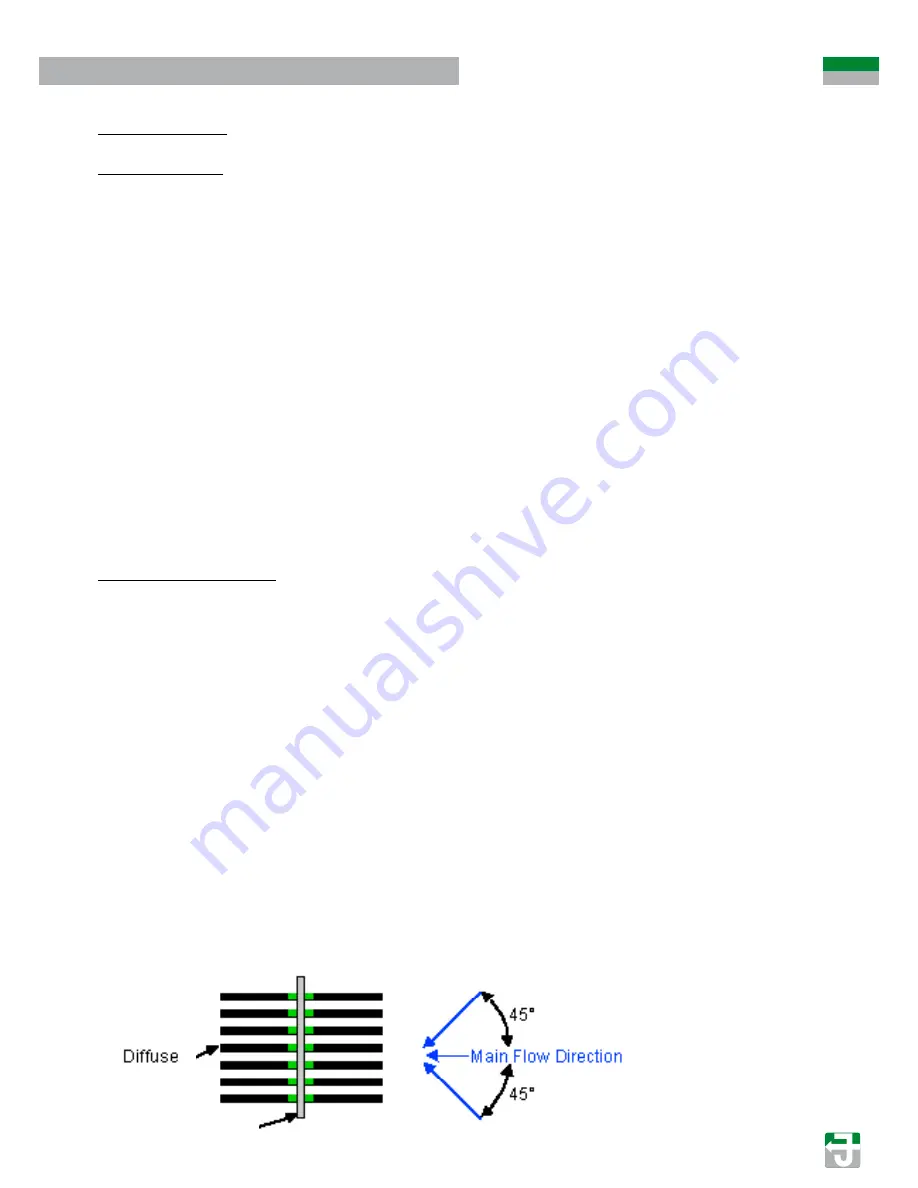

6.2 Diffuser Alignment

• Align the main flow directions of waste water along the diffuser longitudinal axis. Particularly

for the JetFlex TD 63/2100 D this leads to a reduction of the oscillation load.

• Choose a minimum distance of accelerators to diffusers and a maximum velocity of flow

around the diffusers does not exceed 0,5 m/s.

Header

r