38

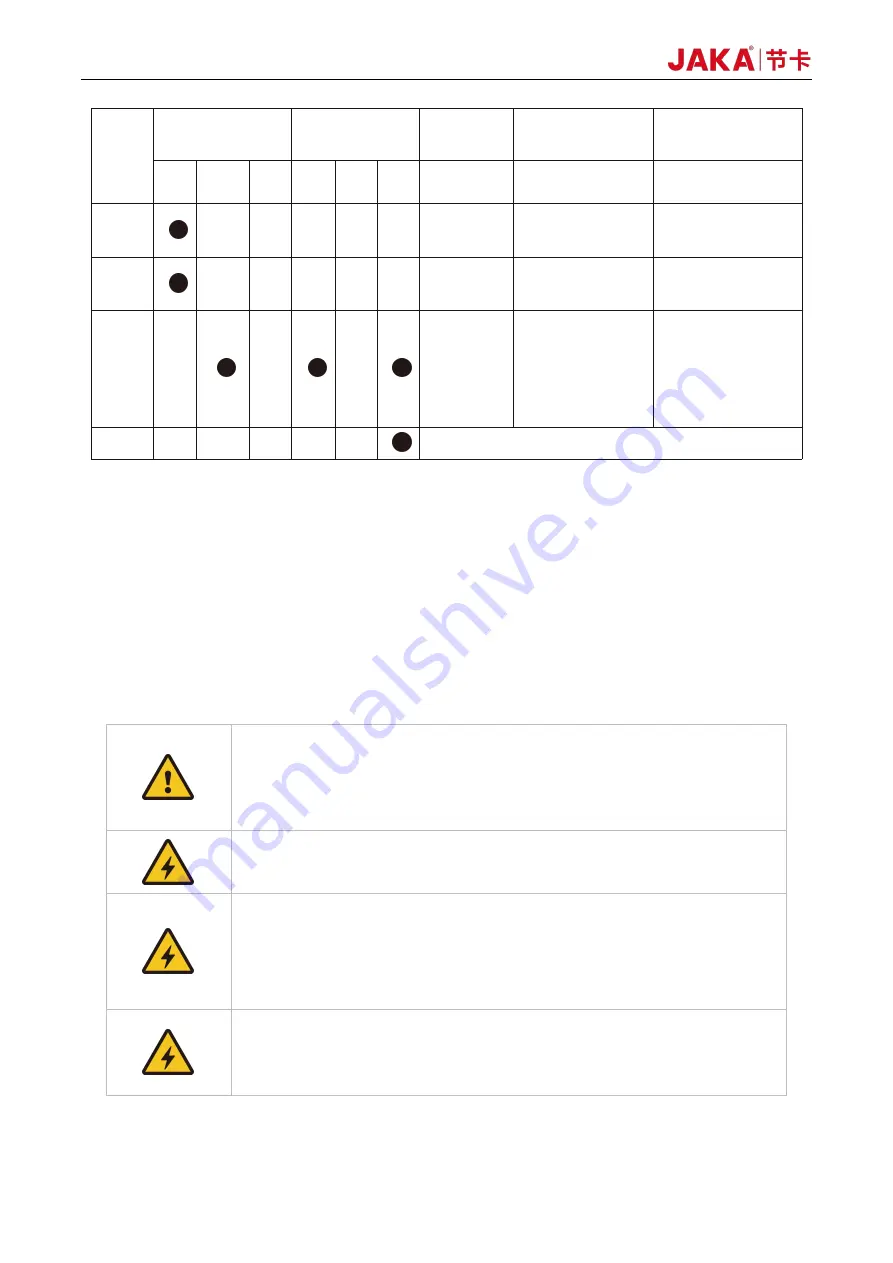

Verification

number

Inspection cycle

Maintenance

Inspecting

Parts

Inspecting Content

Inspection/process

ing method

Daily

Every 3

months

Every 1

year

4 year 5 year 8 year

1

Surfaces

Whether there is

splashes, dust, etc.

Visual confirmation,

cleaning

2

Filters

Whether there is dirt or

blockage

Visual confirmation,

cleaning, replacement

3

Cables

Confirm whether there

is any damage or

fragmentation

•Confirm whether the

connectors are loosed.

Visual confirmation,

tightening. Replace the

cable when it is

obviously damaged.

4

Overhaul

(P.S.) Use a soft cloth to remove dusts when cleaning. Do not blow off dust with equipment such as air

blowers. Wind pressure will cause the dusts to enter the inside of the fan and the blades rotate at a speed

exceeding the rated speed, which may cause the fan to malfunction or affect its life. Only use the vacuum

cleaner on the blade section. Do not vacuum the rotating part or the main body, which can cause the fan to

malfunction or reduction of the fan’s service life.

5.3 Parts Replacement and Preservation

When replacing the parts of the robot control unit, please observe the following precautions and work

safely.

1

、

Do not carry out any modification of our products.

2

、

Fire, malfunction, and wrong movements caused by modification may result

in personal injury or damage to the robot.

3

、

Any loss caused by the user's own modification of JAKA's products is not

covered by JAKA’s warranty.

1

、

To prevent electric shock, when replacing parts, please turn off the circuit

breaker, and then turn off the main power supply.

1. Turn off the main power, wait for 5 minutes, and then the parts could be

replaced if needed.

2. There is a risk of electric shock, due to residual charge in the electronic

components.

3. Do not use wet hands for work.

4. In case of electric shock, it will result in serious injury or death.

1. 1.The replacement must be carried out by the specified operator.

2. 2.Electric shock or being caught by a robot accidentally can result in serious

injury or death.

JAKAZu 5