Maintenance

8

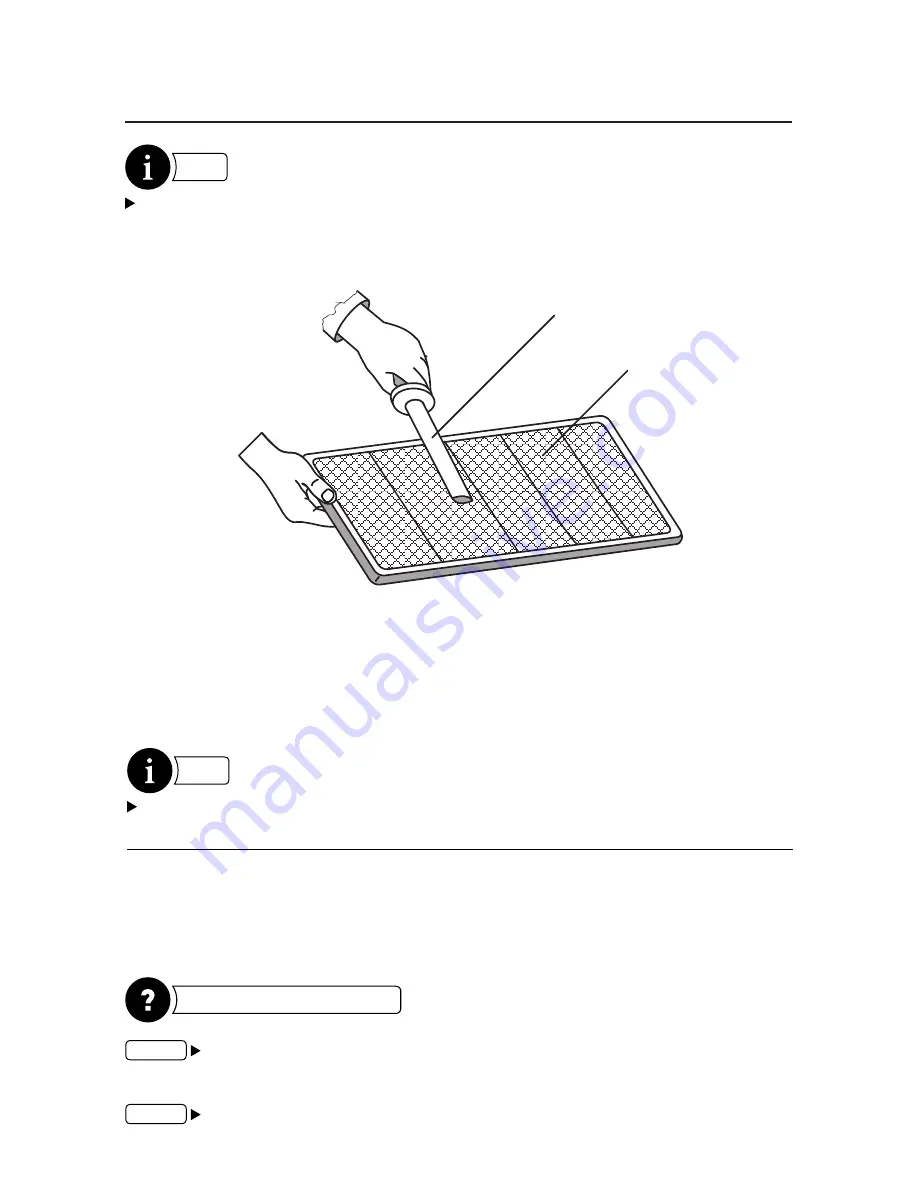

Filter

Vacuum Cleaner

Clean the filter with a vacuum cleaner. To remove dense dust build-ups, prepare

a solution with cold water and natural detergent or soap powder and submerge the

filter in the solution. Later pull out the filter from the solution and leave it to dry. In any

case, do not scrub or apply force on the filter material. After it is completely dry, mount the

filter to the unit, close the service door and tighten the screws thoroughly.

NOTE

JAKKA Controllers for this

u

nits have a preset timer to monitor filter occupancy

a

ccording

to factory set timer

.

Re

mote controller informs the user to check the filters. After the

filters are cleaned by the

user, filter warning alarm must be reset.

NOTE

It may be

handy

to keep

spare

clean

and dry

filters

for quick r

eplace

ment

of

dirty

filters to

minimize unit downtime for filter maintenance.

Exchanger

Maintenance

For best performance, c

lean up the air

exchanger

periodically.

If the filters are maintained regularly, clean exchanger at least once in every two years.

STEP 1

To open the service

cover that is located on the bottom side of unit

,

unscrew and

remove out 4 screws

that secure the heat recovery exchanger service cover

.

STEP 2

While performing removal of service cover make sure heat recovery exchanger

does not fall down.

HOW TO ACCESS

EXCHANGER