Page 9 of 11

Assembly Instructions: Multi Section Cupboard

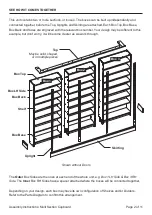

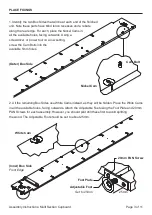

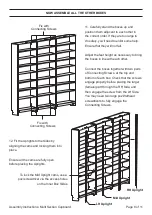

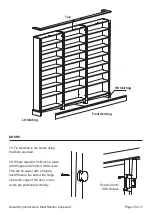

13. Fit Dowels into the Front Skirt holes, and push home the Front Skirt into the holes on the Uprights

and Valances. This can be glued into place, or left as is. Depending on your design, you may have LH

and/or RH Skirts. If you wish, you can scribe these Skirts to match your room skirting. When placing

the LH & RH Skirts, ensure that the mitre matches neatly with the Front Skirt. They can be either

glued in place, or screwed from the inside using 30mm CSK Screws.

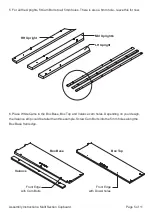

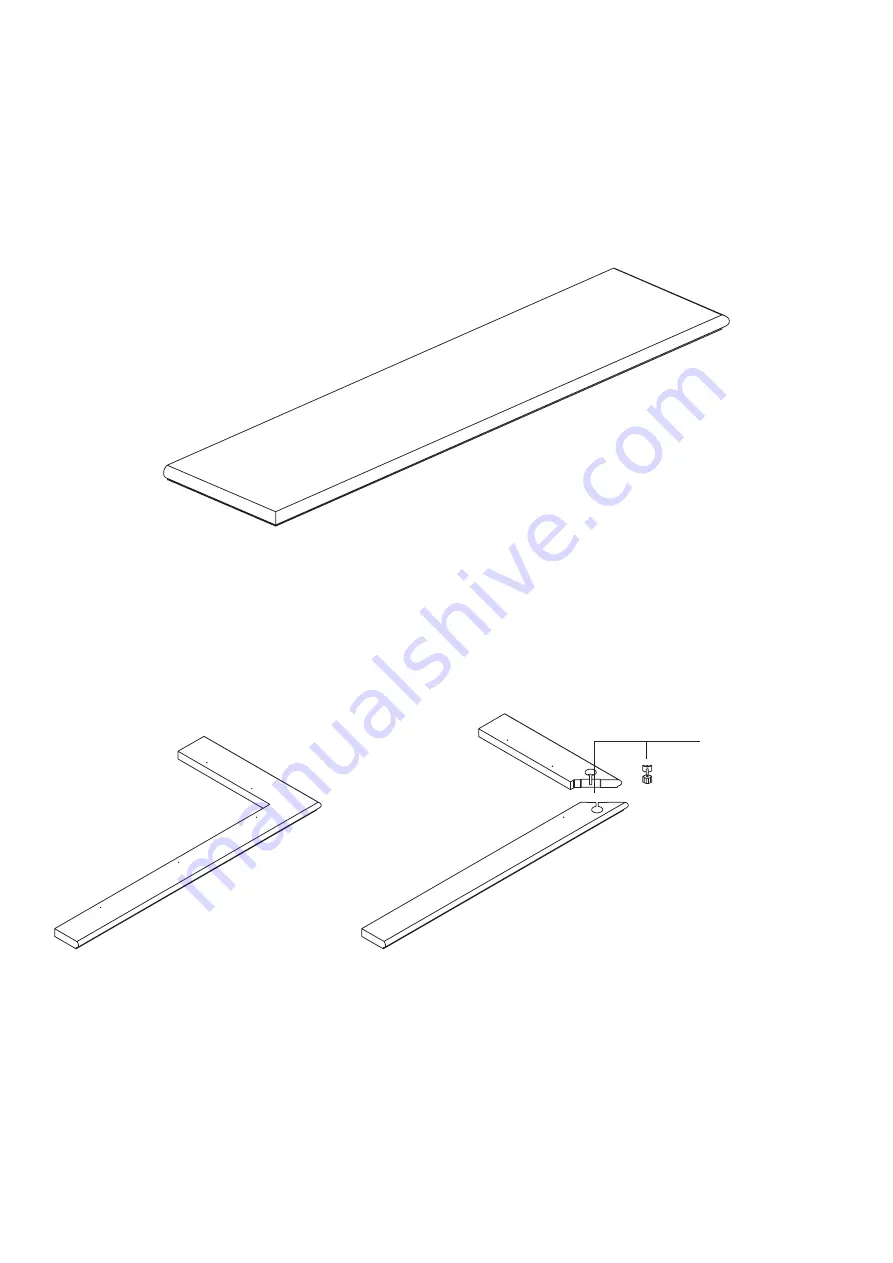

14. Depending on your design, you may have one of a variety of different Top styles. The most

common is simply a solid Top board.

Alternatively, you may simply have a Top ‘lip’. This can be located using Dowels, and glued or

screwed from above. This may be supplied as one single component or several parts which join

together with a Connector (using the hex key provided) once in place.

Full Top

Top Lip Set

Top Lip

Fix with

Connector

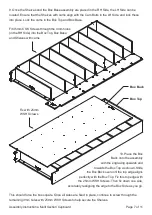

Locate the Top to the Box Tops using Dowels. It can be glued into place, screwed into place from

beneath, or left as is. For 30mm Tops, use 45mm CSK Screws. For 18mm Tops, use 30mm CSK

Screws. For exceptionally wide units, the Top and Skirting may be supplied in several lengths.