9

No. Item

Material

1.

Top handle

ABS

2. Lid-window

AS

3. Lid-top

ABS

4. Lid-bottom

ABS

5.

Top ring

ABS

6.

Stainless steel handle

SUS 304

7.

Basket foldable handle 1

ABS

8.

Basket foldable handle 2

ABS

9.

Plastic basket

ABS

10.

Left up handle

ABS

11.

Left down handle

ABS

12.

Silicone seal

Silicone rubber

13.

Left cover

ABS

14.

Stainless steel tank

SUS 304

15.

Front cover

ABS

16.

Spout

SUS 304

17. Washer

AL

18. Nut

AL

19.

Hose

Silicone rubber

20. Nut

ABS

21. Spout

ABS

22.

Ball valve

Standard part

23. Bracket

ABS

24.

Valve handle

ABS

25. Elbow

ABS

26.

Inner tank

ABS

27.

Bottom cover

ABS

28.

Power PCB 1

94Vo

29.

Power PCB 2

94Vo

30.

Right cover

ABS

31.

Right down handle

ABS

32.

Right up handle

ABS

33.

Transducer PCB

94Vo

34.

Right panel

ABS

35.

Cooling fan

Standard part

36.

Power switch PCB

94Vo

37.

Power switch

Standard part

38.

Power socket

Standard part

39.

Back cover

ABS

40.

Cover holder

ABS

41.

Hose

Silicone rubber

42.

Thermal cut-off

A0-3A-F

43.

Heater cover

PA 66

44.

Heater pocket

PA 66

45.

Thermocouple holder

ABS

46.

Button pad

94Vo

47.

Light socket

ABS

48. Film

PC

49.

Control panel box

AS

50.

Control panel cover

ABS

51.

Key pad cover

TRP 40°

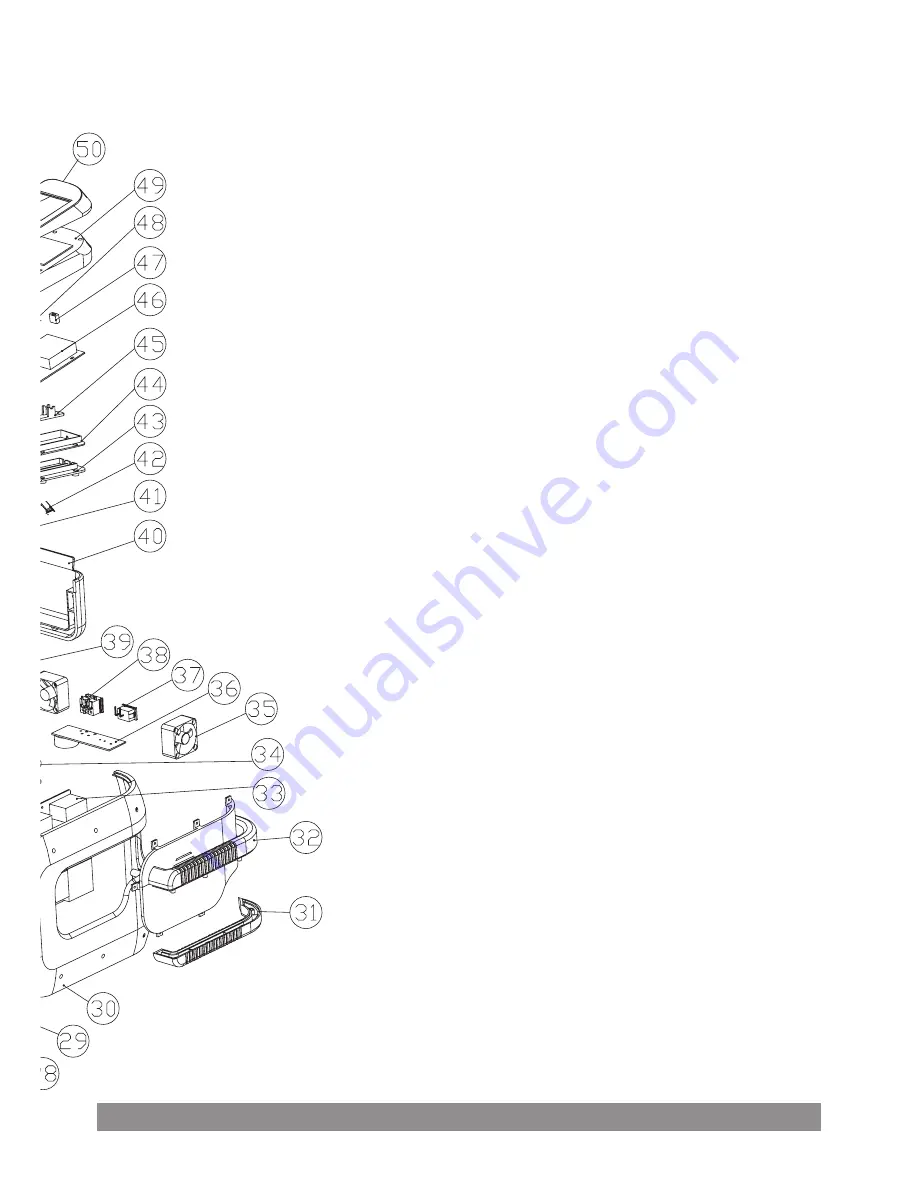

Summary of Contents for ULTRA 9020

Page 10: ...8 PRODUCT EXPLODED VIEW...