basic

saw

operations

Familiarize yourself with the following functions of the 14" Metal Cutter before connecting it to a power source

and using it.

1. When starting this 14" Metal Cutter for the first time or after it has been idle for a while, always let the machine

run for one full minute with the blade completely recessed into the guard before making any cuts. If the

blade wobbles or vibrates, discard and replace it immediately.

2. When beginning a cut with the saw, care should be taken not to bump or slam the blade into the work.

Once it has entered, continue the cut with an even smooth stroke. The faster a cut is made the less heat is

created in the work piece preventing discoloring and blade life is prolonged. Cut with maximum force without

overloading the motor.

3. Use an independent support when cutting long, heavy pieces to prevent them from tipping the saw or falling down

after they are cut.

4. When transporting the saw, secure the motor mount to the base to prevent damage.

5. When blade comes up to full speed, pull the handle to begin cutting. It is important to cut with steady and even

pressure (Do Not Force) in order to have consistent cuts.

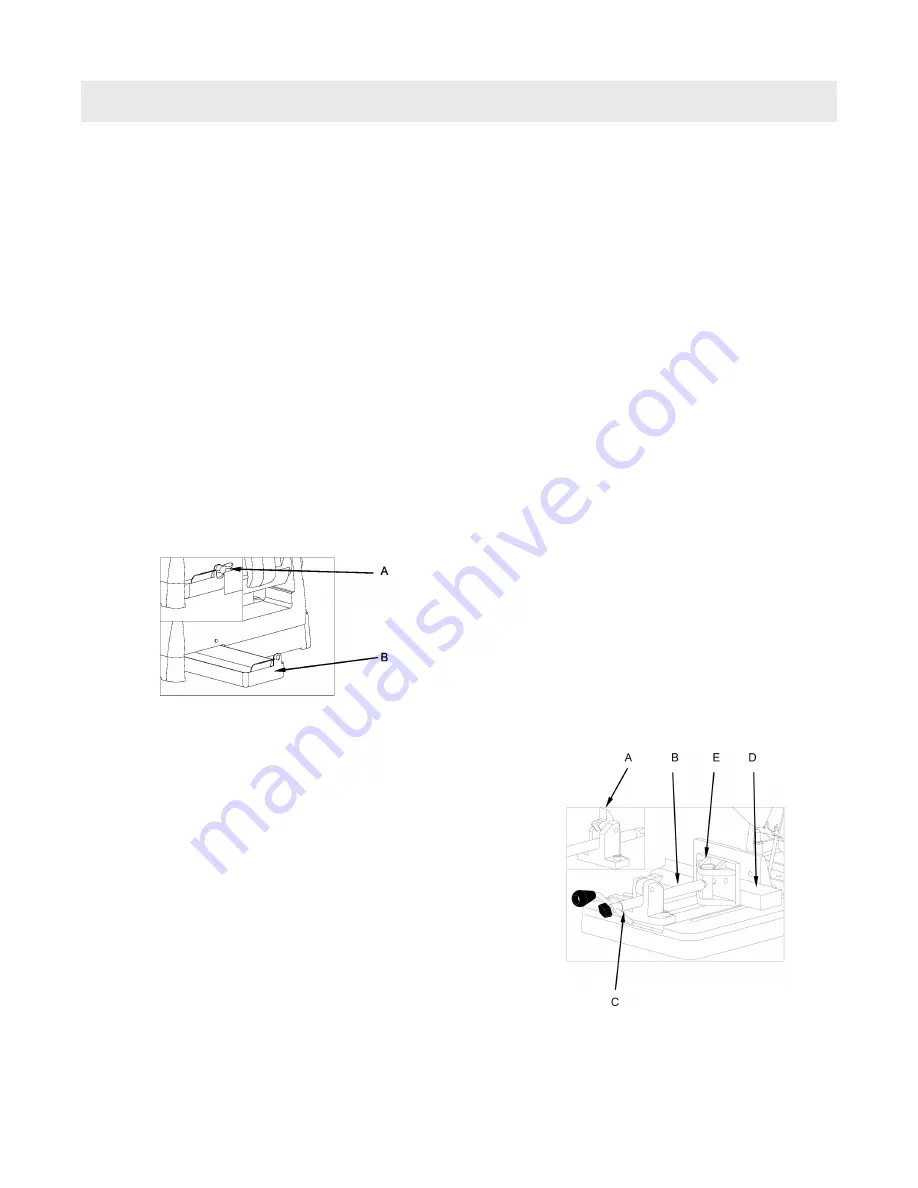

CLEAN CHIP COLLECTOR

Loosen the screw (A), take out the chip collector (B) and clear it. Put the chip collector (B) back and re-tighten the

screw (A).

THE QUICK VISE

Clamping the work piece can be accomplished quickly and easily as

follows:

1. Lift thread-nut (A)

2. Pull out screw handle (C) far enough to allow work piece (D) to be

placed in vise opening against rear vise jaw (E) as shown.

NOTE: It is not necessary to thread screw handle (C) when the

thread-nut (A) is in the raised position. The screw handle

(C) can be rapidly pulled out or pushed in.

3. Push screw handle (C) until front vise jaw (E) contacts the work

piece (D).

4. Flip thread-nut (A) over to engage vice screw (B) and tighten

screw handle (C) to securely clamp work piece (D) in the vise.

10

Summary of Contents for Slugger MCCS14

Page 14: ...saw breakdown 14 ...