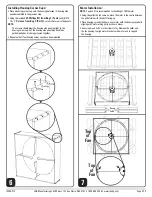

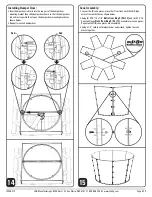

Cone Installation:

• Using (2) people lift the cone assembly onto the housing assembly.

— With J&D logoed cone sections facing the sides (not the top and

bottom) line up the edge of one of the cone pieces to the center

line of the housing.

— Make sure the raised part of the rubber gasket is inside the

cone assembly and not underneath it or crushed anywhere.

NOTE:

During the following process of securing the cone to the housing,

recheck the rubber gasket for proper placement and make adjust-

ments as needed

IS295-21C

J&D Manufacturing • 6200 Hwy 12 • Eau Claire, WI 54701 • 1-800-998-2398 • www.jdmfg.com

Page 9/13

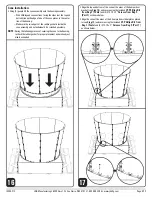

• Align the top and bottom of the cone at the areas of the damper door

bracket (see

Step 10

) and secure using the included

#3 Phillips Bit

from Bag 1 (Tools)

and

(4) #14-10 x 2”

Screws from Bag 5

(Part 1)

as shown below

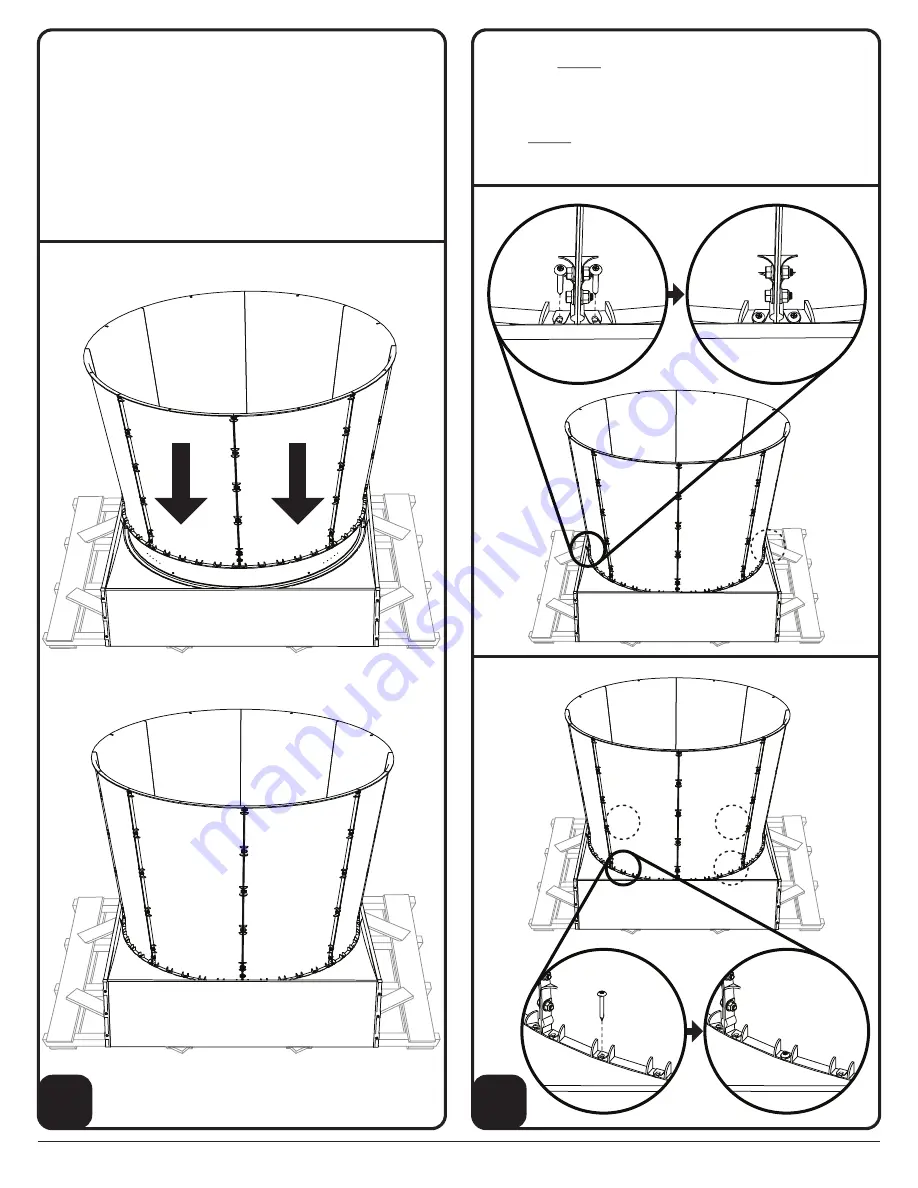

• Align the cone at the areas of the 4 damper door striker plates placed

in (see

Step 12

) and secure using the included

#3 Phillips Bit from

Bag 1 (Tools)

and

(4) #14-10 x 2”

Screws from Bag 5 (Part 1)

as shown below

16

17