Issue: 01.03.2016

Page 6

8.

Air Flow Calculations

For effective operation, the cellar will require between 6 to 10 air changes per hour. To calculate the fan speed setting needed to

achieve the required air change:

•

Calculate room volume in m³ (L x W x H)

•

Multiply the resulting room volume by a value between 6 and 10 (air changes/hour) to achieve a required figure in m³/h.

•

Check the figure against the airflow values (m³/h) for the fan given in Section 4 on page 4 and select the fan speed which

best matches this.

The JABC unit comes with a rear entry air inlet connection for direct attachment to an external facing wall (through-wall installation).

If an external facing wall is unavailable, the JABC unit can be mounted in a suitable location, with the air inlet connection changed to

bottom entry. This is done by exchanging the rear inlet spigot with the bottom entry sealing plate for ducting purpose. Please see

page 7

for instructions on how to change the inlet spigot position.

When connecting ducting to the JABC unit, it is recommended that any increase in pressure resistance should be limited as follows:

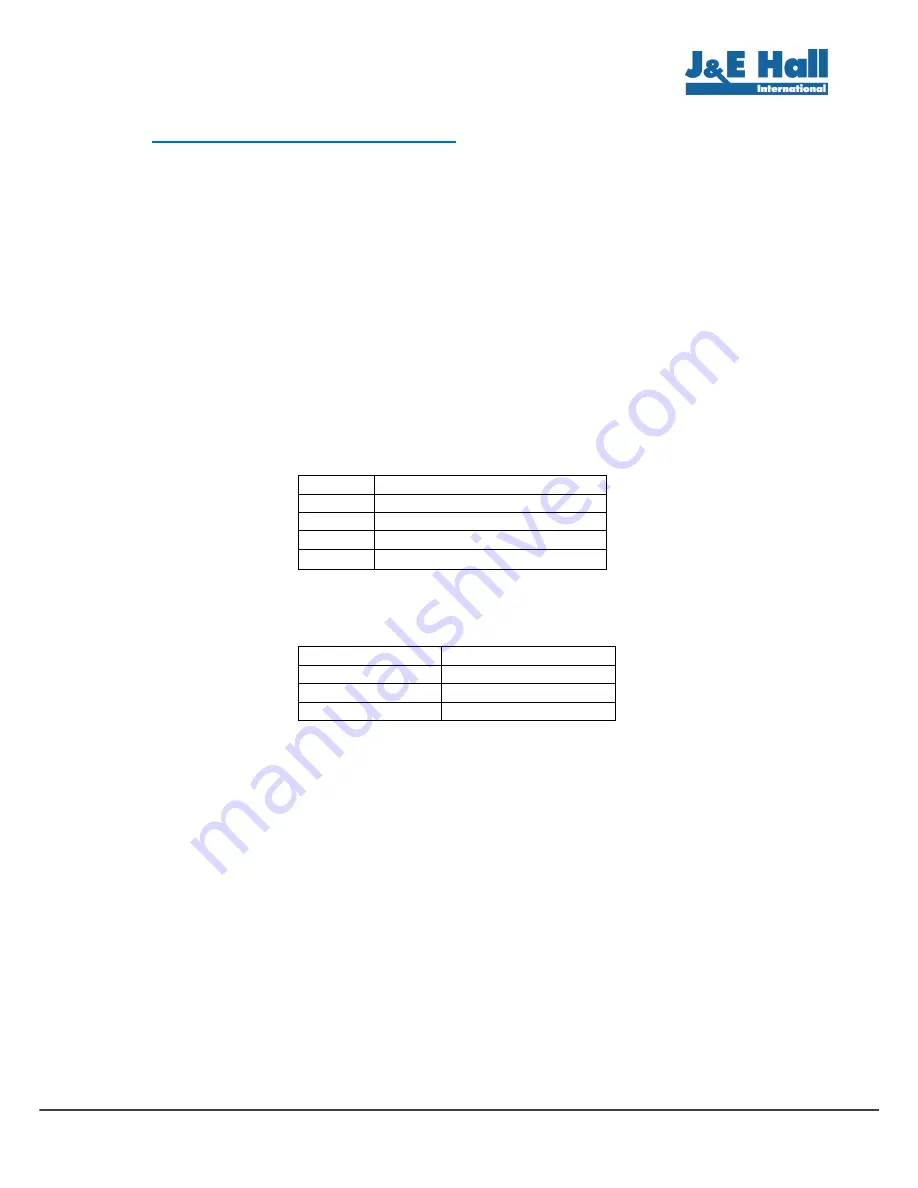

Fan Speed Maximum Pressure Resistance (Pascals)

4

90

3

118

2

114

1

60

For 150mm nominal diameter lightweight ducting, the following standard industry values can be used to calculate the pressure

resistance for the proposed ducting run:

150mm Circular Duct

Pressure Resistance (Pascals)

1 metre straight length

7

1no. 90 degree bend

15

1no. 45 degree bend

7.5

Example calculation:

Room volume is 6m x 5m x 2.4m (72m³). Multiply this figure by 8 (air changes/hour). This gives a required figure of 576m³/h. Either

fan speed 3 or 4 will give the required airflow to achieve 8 air changes per hour.

Installation requires: 6m of straight ducting, 2no. 90 degree bends and 2no. 45 degree bends

Calculation: (6 x 7 Pascals) + (2 x 15 Pascals) + (2 x 7.5 Pascals) = 87 Pascals

Assessment: 87 Pascals resistance is within the limits of the fan at either fan speed 3 or fan speed 4.

Please Note:

Fan speed 1 should only be used for through-wall applications with small room sizes. For extended ducting application, we do not

recommend using the unit with fan speed 1. Regardless of room size, please select either fan speed 2, 3 or 4 only.