14

1.0 Operations

8.

Open door on Speed Tender using supplied remote. (Figure 1.4).

WARNING: Empty-out the rear compartment first to help prevent the chance of flipping the

Speed Tender.

9.

Use the Handheld Control or Wireless Remote to start the conveyor/auger.

10.

Fill the planter/drill to desired level then repeat.

NOTE: Adjusting engine throttle will regulate conveyor/auger speed.

11.

Close door on Speed Tender before the last planter seed box is full so you can completely empty-out collapsible hopper

and conveyor/auger.

CAUTION: If you are parked on an incline the boom arm may swing freely. (It is advised that you do not use the

Speed Tender on uneven ground).

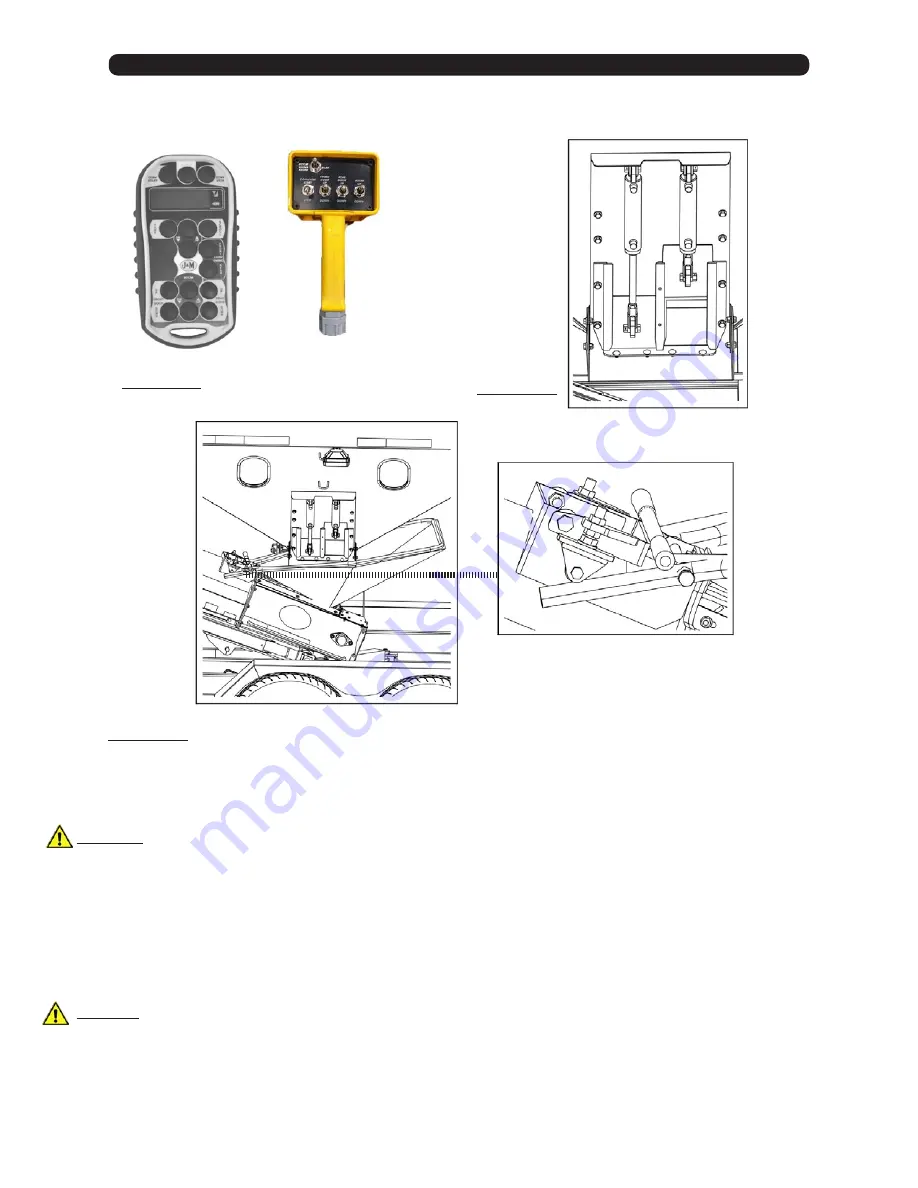

Figure 1.6

Figure 1.4

See Section 4.1 for Remote Options

Figure 1.5

Wireless

Remote

Handheld

Control

Hopper Up

Hydraulic

Door

Assembly

Summary of Contents for 510-ST

Page 3: ...3...

Page 9: ...9 Decals 4 11 13 7 12 14 9 10 11 16 15 17...

Page 33: ...33...

Page 55: ...55...

Page 57: ...57 5 0 Parts Includes 6 Dia Clamp with M10 X 1 1 2 L Bolt 5 6 7 8 9...