11

Initial Operation & Maintenance

Initial Operation

WARNING: Ensure all power is shut off before servicing the gravity wagon.

Before the gravity wagon is put into service, check the following items for safe operation:

•

The track assembly for the door has proper lubrication for less wear on the sprocket and track and easier door operation.

•

The SMV (Slow Moving Vehicle) sign is positioned with a point of the triangle upward and as near to the rear and centered or as near

to the left of center of the unit as practicable. The lower edge of the sign should be located 2-10 feet above the ground.

•

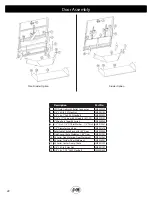

The gravity wagon is properly attached to the running gear. If no rocking bolster is used, bolt all four corners (use 1/2” bolts

provided) of the gravity wagon runners to the running gear. (If the box is used in rough terrain, bolt a minimum of two corners and

chain (or cable) the remaining corners to allow more box flexibility.

•

Check all braces, bolts, nuts, lug bolts, and lug nuts been checked to ensure they are properly fastened.

The proper torque for the

wheel lug nuts is 350 ft lbs.

•

All operators of this machine have read and clearly understand the safety instructions.

•

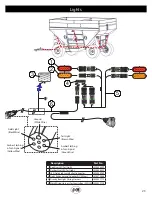

All lights must work properly. All reflective decals are clean, visible, and positioned correctly.

•

Tires are properly inflated. The following is to be used as a

general guide

for tire inflation for cyclic use. Figures can vary depending

on specific brand of tire used.

It is important that tires are inspected before and after the unit is loaded. The tire should stand

up with no side wall buckling or distress as the tire rolls.

Do not exceed the tire pressure indicated below:

WARNING: Tow loads safely

Stopping distance increases with speed and weight of towed loads, and on slopes. Towed loads with or without brakes that are too

heavy for the tractor or are too fast can cause loss of control. Consider the total weight of the equipment and its load.

For towed equipment WITHOUT brakes, the following is recommended:

Do NOT tow equipment that does not have brakes at speeds over 32 km/h (20 mph); or that, when fully loaded, has a mass (weight) over

1.5t (3300 lb) and more than 1.5 times the mass (weight) of the towing unit.

For towed equipment WITH brakes, the following is recommended:

Do NOT tow equipment that has brakes at speeds over 40 km/h (25 mph); or that, when fully loaded, has a mass (weight) more that 4.5

times the mass (weight) of the towing unit.

Ensure the load does not exceed the recommended weight ratio. Use additional caution when towing loads under adverse conditions,

when turning and on inclines.

WARNING: Before filling the gravity wagon, make certain that no one is inside the grain tank. Never allow children or

anyone in, near, or on the gravity wagon during transport or during loading or unloading of grain. Be aware that moving grain

is dangerous and can cause entrapment, resulting in severe injury or death by suffocation.

After hauling corrosive materials such as fertilizers, be sure to wash out the grain tank to prevent premature rusting. Bare spots on

metal should be primer coated before applying the outer surface paint.

Check the box periodically for cracks in welds and for other structural damage. Have cracked welds fixed immediately. Failure to

do so could result in extensive damage and greatly reduce the life of the gravity wagon.

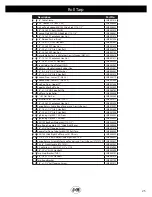

Tire Size

psi

425/65R22.5

85

445/65R22.5

85

Summary of Contents for 655

Page 2: ......

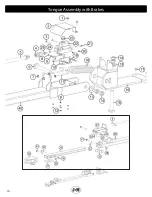

Page 16: ...16 Tongue Assembly with Brakes...

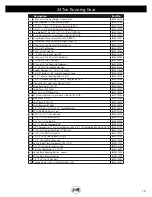

Page 18: ...18 24 Ton Running Gear 45...