Page 7

5. Drill out a ½" hole and insert the round seal supplied

with the kit. A remote cable will run through the middle

hole of the backplate and into the electrical box.

2.5

Installation of the Backplate on a Flat

Wall

CAUTION

Do not expose the user interface to direct sunlight. Too

much direct sunlight will darken the LCD screen, and it

will no longer be readable.

1. Turn off the pump at the control panel.

2. Turn off all electrical power to the pump at the main

junction box or at the circuit breaker providing electrical

power to the pump.

WARNING

ELECTRICAL SHOCK HAZARD

Turn off all switches and the main breaker in the ePump™

electrical circuit before starting the procedure. Failure to

comply may cause a shock hazard resulting in severe

personal injury or death.

3. A minimum of two (2) fasteners (installer supplied) are

required when installing to a flat wall to hold the user

interface securely.

4. The backplate has ten (10) mounting holes to choose

from. Only drill out the plastic film from the holes to be

used. See Figure 2.

5. Mark the hole locations on the wall and use the fastener

to secure the backplate to the wall.

6. At the bottom of the backplate, cut the two (2) tabs

out with an appropriate tool, such as a carton cutter or

an exacto knife, and route the cable through the open

channel.

2.6

Connection to the Jandy ePump

TM

Variable Speed Pump

The following steps provide the procedure for installing the

user interface to a Jandy ePump™ variable speed pump.

1.

Turn off all switches and the main breaker that

supplies power to the pump.

WARNING

ELECTRICAL SHOCK HAZARD

Turn off all switches and the main breaker in the pump

electrical circuit before starting the procedure. Failure to

comply may cause a shock hazard resulting in severe

personal injury or death.

2.

Remove the cover of the pump junction box.

3.

Feed the RS-485 cable into the tting.

NOTE

The user interface uses a four-wire RS-485 interface

to communicate with the ePump™.

4.

Unplug the RS-485 connector from the pump.

5.

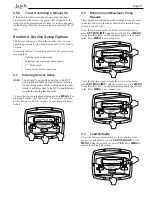

Attach the four (4) wires in the RS-485 cable to the

RS-485 connector. Make sure the colors match the

positions on the connector. See Figure 2.

6.

Connect the RS-485 connector back into the pump.

7.

Set the DIP switch settings for the pump controller

with the 1 and 2 in the ON position and 3 and 4 in

the OFF position. See Figure 3.

8.

Turn on all switches and the main breaker feeding

power to the pump.

9.

Verify the operation of the controller. If the

controller displays

FAULT PUMP NOT

CONNECTED

, re-check the wiring and the DIP

switch address setting on the pump.

Jandy ePump

¥

(Rear View)

RS485

4 3 2 1

REMOTE CONTROL

5 4 3 2 1

User Interface

(Rear View)

RS485 Cable

2 BLACK

3

YELLOW

1 RED

4 GREEN

4-Position

DIP Switch

SW 1

SW 2

SW 3

SW 4

Figure 3.

Wiring the User Interface to the Jandy

ePump

TM

Variable Speed Pump

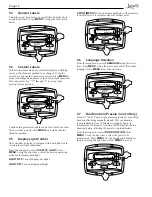

2.7

Jandy ePump™ Variable Speed

Pump Switch Settings

For the ePump™, the 4-position dip switch is located at the

rear of the pump, as shown in Figure 3.

This dip switch serves two functions, it determines what

type of control will be used with the pump and it selects the

pump address. The SW 1 (switch 1) and SW 2 are turned ON

if the pump is to be controlled by a stand alone controller or

OFF if the pump is to be controlled by the AquaLink

®

RS or

AquaLink

®

PDA.

SW 1

SW 2

CONTROL

OFF

OFF

AquaLink

®

RS

AquaLink

®

PDA

ON

OFF

OFF

ON

ON

ON

Stand Alone

The SW 3 and SW 4 are turned ON/OFF to select the Pump

address.

SW 3

SW 4

PUMP No.

OFF

OFF

1

ON

OFF

2

OFF

ON

3

ON

ON

4

Summary of Contents for ePump

Page 2: ......