Page 16

ENGLISH

Jandy

®

Pro Series, Hi-E2

®

and Hi-E2R Gas-Fired Heater

|

Installation & Operation Manual

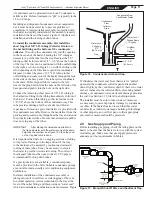

Figure 21. Piping to heater.

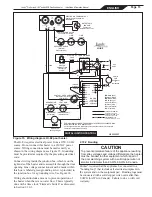

Figure 22. Pressure relief valve installation.

Water In

Out

Method For Installing

Any Threaded Pipe

For Nonthreaded Pipe

or Tube, Discard

Plastic Sleeve

Use

Plastic

Sleeve

pool surface a leak can result in large scale water loss or

flooding. Zodiac cannot be responsible for such water loss

or flooding or the damage caused by it.

Do not install a shutoff valve or any kind of variable

restriction in the water piping between the heater outlet

and the pool/spa.

Pool systems with water flow rates higher than 100 GPM

require an adjustable external bypass at the heater. See the

section on start-up and adjustment for this information.

2.11.3 Connections at Heater

The Hi-E

2

has a universal water header and flange design.

With this feature, a variety of piping materials and sizes

can be used at the heater. 1-1/2" PVC or 2" copper pipe

can be connected directly to the heater using the rubber

“donut” gaskets provided with the heater. 2" PVC or metal

pipe can be threaded directly to the flanges and 1-1/2"

schedule 40 metal pipe can be used with the rubber donut

gaskets. See Figure 21.

2.11.4 Pressure Relief Valve and

Temperature Relief Valve

A pressure relief valve (PRV) is recommended in all

installations, and is mandatory in any installation in which

the water flow can be restricted between the heater outlet

and the pool/spa. A pressure relief valve may also be

required by local codes and a pressure relief valve must

be provided in Canada. Be sure to check any applicable

installation codes in your area to determine whether a

pressure relief valve is required.

A pressure relief valve is not supplied with the Hi-E

2.

All

equipment installations need to be in accordance with the

manufacturers instructions.

To install a pressure relief valve:

1.

Remove the 3/4" brass plug from the top of the

inlet/outlet header, see Figure 22.

2.

Install the pressure relief valve in the opening.

Make sure to get a sung fit. Do not overtighten.

3.

Provide a short length of brass or stainless steel

pipe as necessary to position the valve above the

sheet metal cover.

5.

The final orientation of the pressure relief valve

should be vertically aligned with the discharge

opening facing away from the heater.

6.

Install a discharge pipe from the pressure relief

valve discharge opening to a safe area. This is a

precaution to prevent the possibility of personal

injury or property damage in the event scalding

water is discharged from the pressure relief valve.

7.

Install the discharge pipe so that there is no

trapped or standing water in the piping. Discharge

piping must be facing down, terminating with a

threadless nipple, no less than 6” from floor.

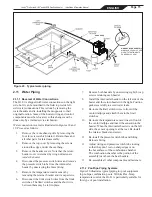

The heater must be protected from back-siphoning of

water, which can result in dry starts. If there is any chance

of back-siphoning, provide a check valve between the

pool and the filter pump inlet.

Arrangement of pool system components other than as

illustrated in these diagrams can affect the operation of

the heater’s water pressure switch. Location of the heater

above or below the pool water surface can also affect

operation of the switch. In general, the pressure switch

can be adjusted to accommodate this effect if the heater

water connections are no more than six feet below the

pool water surface and no more than 15 feet above it. See

instructions for pressure switch adjustment in the heater

start-up section of this manual for more information about

this. Note that when pool equipment is located below the

Summary of Contents for HI-E2

Page 2: ......