Page 8

ENGLISH

Jandy

®

Pro Series, Hi-E2

®

and Hi-E2R Gas-Fired Heater

|

Installation & Operation Manual

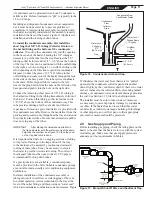

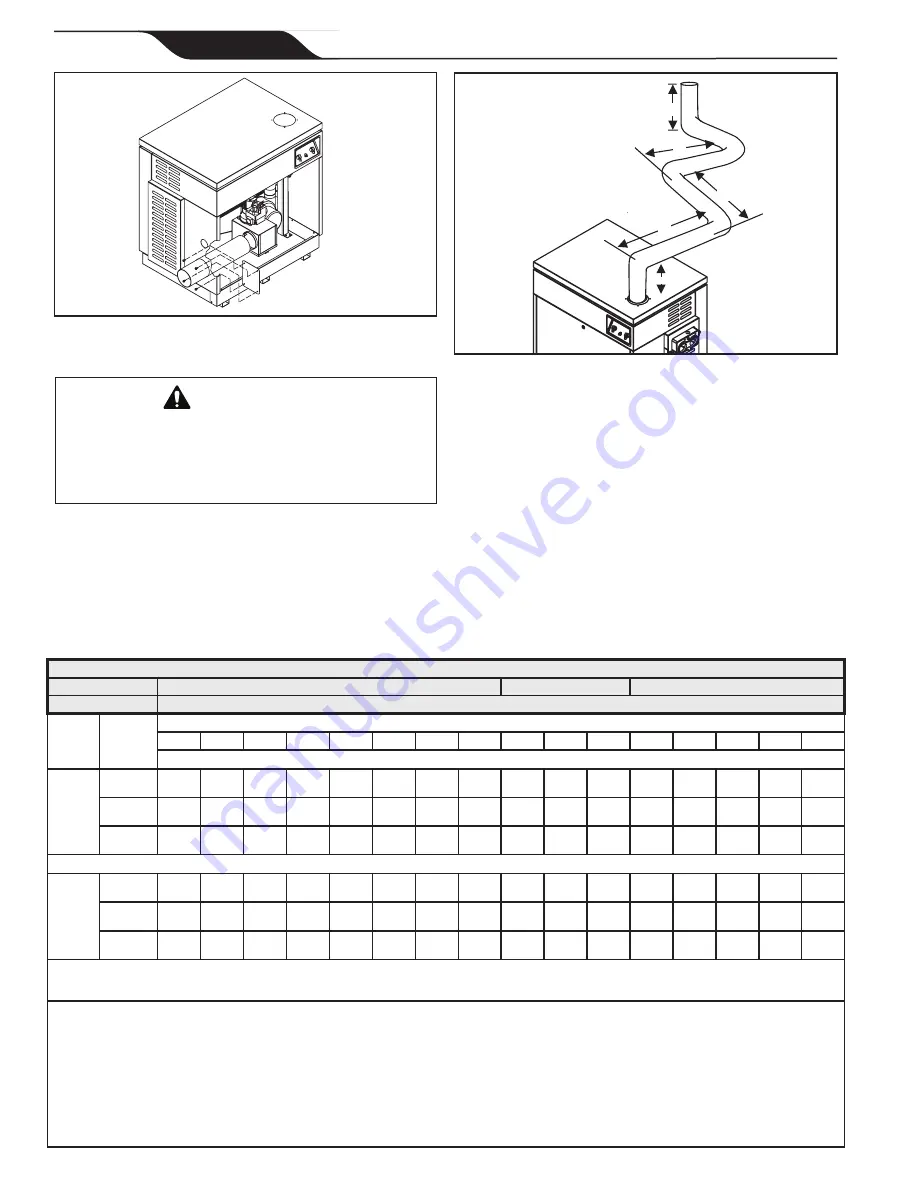

Figure 5. Connection of combustion air pipe to heater.

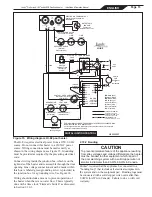

Table 3.

Maximum Combined Length of Combustion Air and Vent Piping in Feet.

Figure 6. “One-pipe” installation.

APPROVED VENTING MATERIALS*

PVC

Class 100, Class 125, Schedule 40 or Schedule 80

CPVC

Schedule 40, Schedule 80

29-4C

®

Stainless steel venting materials listed for venting of condensing gas-fired appliances.

Model

Pipe Size

Inches

(cm)

Number of Elbows

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Total Length of Pipe Schedule 40 PVC, Schedule 40 CPVC & 29-4C

®

- Feet (m)

350

4 (10.2)

61

(18.6)

50

(15.2)

39

(11.9) 27 (8.2) 16 (4.8)

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

5 (12.7)

225

(68.6)

211

(64.3)

197

(60)

184

(56)

170

(51.8)

157

(47.8)

143

(43.5)

130

(39.6)

116

(35.4)

116

(35.4)

NA

NA

NA

NA

NA

NA

6 (15.2)

573

(174.7)

556

(169.5)

538

(164)

521

(158.9)

503

(153.3)

484

(147.5)

465

(141.7)

446

(135.9)

426

(130)

426

(130)

383

(116.7)

360

(110)

336

(102.4)

310

(94.5)

283

(86.3)

255

(77.7)

Total Length of Pipe Schedule 80 PVC & Schedule 80 CPVC - Feet (m)

350

4 (10.2)

48

(14.6)

36

(11.0)

24

(7.3)

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

NA

5 (12.7)

173

(52.7)

161

(49.1)

149

(45.4)

137

(41.8)

125

(38.1)

113

(34.4)

101

(30.8)

89

(27.1)

NA

NA

NA

NA

NA

NA

NA

NA

6 (15.2)

438

(134)

426

(130)

414

(126)

402

(123)

390

(119)

378

(115)

366

(112)

354

(108)

342

(104)

330

(101)

318

(96.9)

306

(93.3)

294

(89.6)

282

(86.0)

270

(82.3)

258

(78.6)

NOTES

1. Vent must be Class 100, 125 or Schedule 40 PVC or CPVC, Schedule 80 PVC or CPVC. Combustion air pipe may be PVC, CPVC or suitable metal pipe.

2. Heavy condensation occurs in long vent pipes. Provide a separate entrapped condensate drain from vent piping near heater when 5” vent pipe exceeds 100 feet or 6” vent pipe

exceeds 50 feet.

*

• For saltwater version heaters (EHE350NS and EHE350PS) a 180°F vent limit switch is required and PVC venting is not allowed.

•

All metal sections of the venting system used must be stainless steel and listed/certified/classified by a Nationally Recognized Testing Laboratory (NRTL) as

being compliant with the applicable requirements of the Underwriters Laboratories (UL) standard for safety for “Venting Systems for Gas-Burning Appliances,

Categories II, III, and IV” (ANSI/UL 1738), and properly installed in accordance with any manufacturers’ instructions and in compliance with applicable local and

national installation codes.

•

The non-metallic sections of the venting system installed must also be listed/certified/classified by a Nationally Recognized Testing Laboratory (NRTL) as

being compliant with the applicable requirements of the applicable requirements of the Underwriters Laboratories (UL) standard for safety for “Venting Systems

for Gas-Burning Appliances, Categories II, III, and IV” (ANSI/UL 1738) In addition, non-metallic venting systems may also be listed/classified by a NRTL as

being in compliance with the requirements of the UL standard for “Type BH Gas Venting Systems” (ULC S-636). When installed properly in accordance with any

manufacturers’ instructions and in compliance with applicable local and national installation codes.

2.7.3.3 Size and Length of Combustion

Air and Vent Piping

Piping for combustion air and venting must be large

e

nough to avoid restriction of the heater combustion

system. Pipe diameter, number of elbows and length of

pipe determine how much it restricts flow to or from the

heater. Table 3 specifies the allowable length of piping for

various situations.

The following example illustrates use of table 3:

EXAMPLE:

A model 350 heater is to be installed in a

one-pipe system with schedule 40 PVC or CPVC, see

Figure 6. The vent pipe run is 42 feet long and has

2.7.3.2 Piping Materials

WARNING

To avoid risk of property damage, serious injury, or

death, use ONLY piping materials from the list below

which are certified or listed for the application per

the requirements of UL 1738 and/or ULC S636, by a

Nationally Recognized Testing Laboratory (NRTL).

Vent piping must be corrosion resistant because

combustion condensate is usually present on its internal

surfaces. The materials listed in Table 3. are acceptable

for vent piping:

4'

8'

18'

10'

Total Length: 42'

Total Elbows: 5

EHE350

2'

Summary of Contents for HI-E2

Page 2: ......