Page 14

9. Replace the service door.

10. Turn the rocker switch to ON.

11. Set temperature control to against the

TEMPLOK tab. The main burner should

light. Until the water reaches a temperature

of about 21°C (70°F), it is normal to have

some water accumulating in the base of the

heater.

12. Set the time clock, if one is installed.

3C-2. Relighting the Heater

If the pilot goes out, repeat steps 5 through 7 in

Section 3C-1.

3C-3. Shut-Down Procedure

1. To turn the main burner off, turn the rocker

switch to OFF.

2. To turn the heater off (including the pilot),

press the red button on the gas valve.

3C-4. Putting the Heater In Operation

(Commissioning)

1. When the heater has lit, remove the service

door and check all gas connections for

soundness with leak detection fluid.

2. Check the manifold (burner) pressure setting

and adjust as necessary (see Table 1).

3. Start the adjustment procedure with the

heater cold, on full load, and with the tem-

perature control set at maximum. This will

ensure, as far as possible, that thermostatic

shutdown does not interfere while the pres-

sure is being checked and adjusted.

4. Remove the blanking screw in the manifold

(burner) setting pressure test nipple (see

Figure 18) and securely connect a suitable

gas pressure gauge.

5. Light the heater and allow it to operate for

about 15 minutes to stabilize the burners.

6. Check the pressure and adjust it for the

appropriate heater size. The manifold

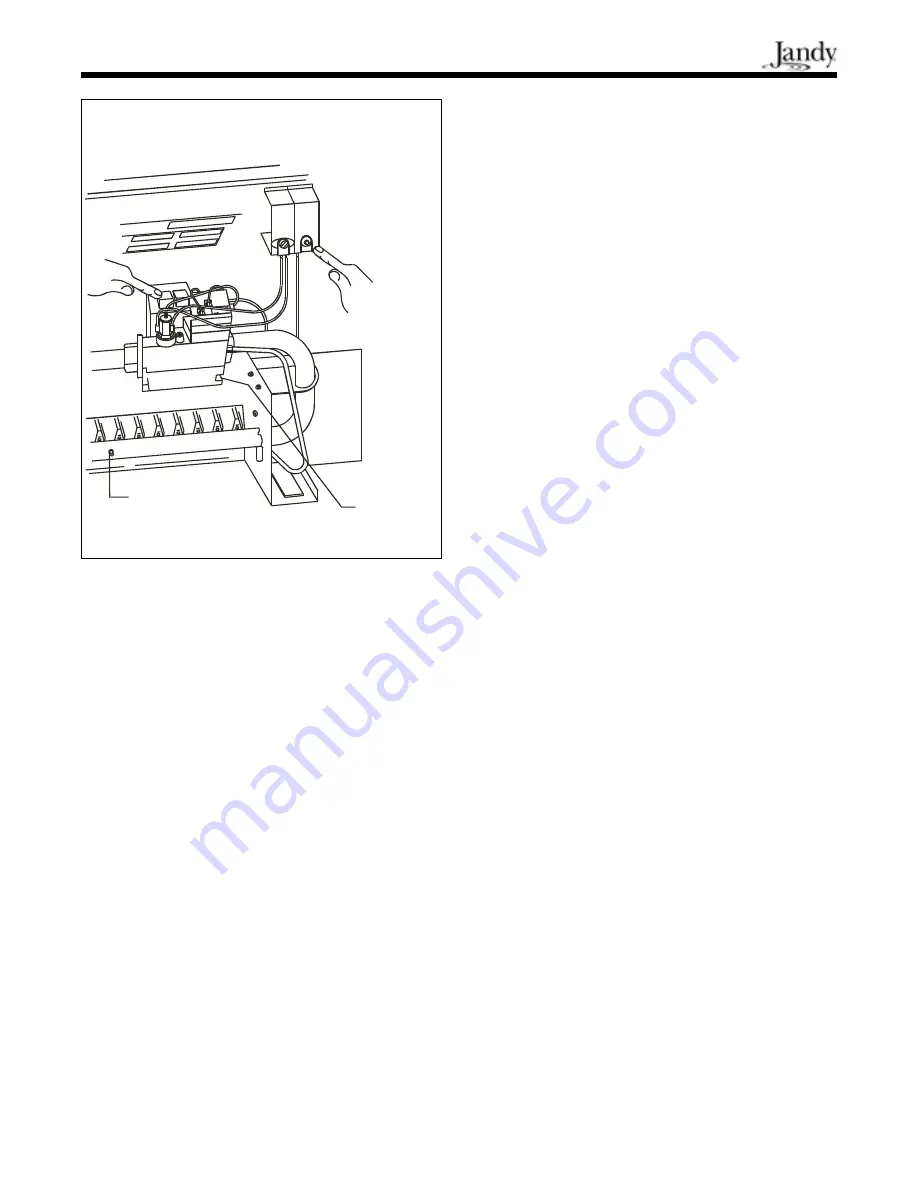

At the same time repeatedly push the button

of the ignitor (see Figure 18) to produce a

spark at the pilot burner. When the pilot has

lit, keep the button on the gas valve fully

pushed in for another 30 seconds.

6. Release the white button and verify that the

pilot is lit.

7. If the pilot burner does not remain lit when

the button is released, press and release the

red button. Wait at least 3 minutes and then

repeat the lighting procedure from step 5.

8. If the pilot cannot be established, check that

the pilot burner flame correctly envelops the

thermocouple tip by 10 to 13 mm. If not,

check that the pilot adjustment screw on the

gas control (see Figure 17) is fully un-

screwed, then turn it one turn back in. Check

that the thermocouple lead connections at the

gas control and at the overheat thermostat

are clean and secure. Repeat from step 5.

Figure 18. Lighting the pilot.

Manifold

Pressure

Setting

Adjustment

Pressure Test

Nipple with Blanking

Screw