Model LG & LD Pool and Spa Heater

Page 3

Notes:

1. An Underwriters' Laboratories listed vent cap is required to prevent downdraft and allow the heater to function properly

and safely.

2. Use approved roof jack.

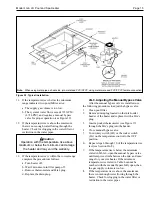

When a drafthood is used, it must be connected to

a vent pipe which stops at least 2 feet (0.61 meters

[m]) above the highest point of the roof or other object

that is within 10 feet (3.05 m) from the vent termina-

tion. The vent pipe must have a listed vent cap which

allows a full equivalent opening for flue products (see

Figure 2).

2C. Site Location

WARNING

Improper installation or maintenance can

cause nausea or asphyxiation from carbon

monoxide in flue gases which could result in

severe injury, or death.

2C-1. Installation Information

Avoid placing the heater in locations where it can

cause damage by water or condensate leakage. If this is

not possible, provide a suitable drain pan to catch and

divert any leakage. The pan must not block natural

flow of air around the heater.

Locate the heater so the clearances from combus-

tible surfaces shown in Table 2 are met.

Table 2. Minimum Heater Clearances From Combustible Surfaces

Figure 2. Indoor Installation Venting (USA), or Outdoor Shelter (Canada).

Table 1. Air Openings to Outside.

Side of Heater

Indoor (Outdoor Shelter) Installation

Outdoors Installation

U.S.

Canada

U.S.

Canada

inch

cm

inch

cm

inch

cm

inch

cm

Blank

6

15.2

6

15.2

6

32

6

15.2

Rear

6

15.2

6

15.2

6

32

6

15.2

Piping

12

30.5

18

45.7

12

30.5

18

45.7

Top

44

111.7

44

111.7

Open Unroofed Area

Front

18

45.7

36

91.4

18

45.7

36

91.4

( )

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

( )

(

)

(

)

(

)

(

)

Required Net Free Open Area

for Combustion Air Openings

Direct from outside

Duct from outside

Model

in

2

(cm

2

)

in

2

(cm

2

)

125

32

(206)

64

(413)

175

44

(284)

88

(568)

250

63

(406)

126

(813)

325

82

(429)

164

(1058)

400

100

(645)

200

(1290)

Note: If using screens and/or louvers, compensate by adding 50%

additional area to each opening.