Model LG & LD Pool and Spa Heater

Page 7

IGN/120

IGN/240

(LI)

(L2)

IGN

TH

VALVE

GND

REMOTE

CONNECTOR

SPA

POOL

OFF

WATER

TEMP

SENSOR

PRESSURE

SWITCH

LIMIT

LIMIT

FIREMAN

SWITCH

CONNECTION

FUSIBLE

LINK

ELEC.

FUSE

MV1

MV2

HONEYWELL

GAS VALVE

BR

IGNITION CONTROL

(FENWAL)

0533

BK

Y/BK

BK

R

W

W

W

Y

Y

CIRCUIT

IGNITOR

IGNITION

CONTROL

L2

IGN

L1

IGN120

or

IGN240

GND

TH

VALVE

MV1

MV2

H/W GAS VALVE

WATER TEMPERATURE

SENSOR

PRESSURE

SWITCH

150 F

HI-LIMIT

SWITCH

O

135 F

HI-LIMIT

SWITCH

O

FIREMAN

SWITCH

CONNECTOR

FUSIBLE

LINK

ELECTRICAL

FUSE

1-25 AMP

TRANSFORMER

24 V

SPA SET POINT

POOL SET POINT

OFF

SEN

SEN

BK

BK/Y

W

Y

BR

W

ONLY 120 V

60 HZ

L2

L1

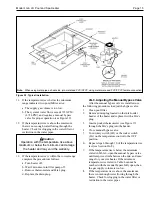

a) Connection Diagram

b) Schematic Diagram

WIRING SHOWN AS SHALL USE

APPLIANCE WIRING MATERIAL RATED AT 200 C.

O

HSI IGNITION WIRE

FACTORY WIRED - 120 V/240 V

FIELD WIRED - 120V /240V

FACTORY WIRED - 24 V

IF ORIGINAL WIRE SUPPLIED WITH HEATER

MUST BE REPLACED, APPLIANCE WIRING

MATERIAL RATED AT 105 C SHALL BE USED.

O

NOTE:

R

Y

W

W

W

W

GND

W

TRANSFORMER

120-240 V

R

Y

BK

W/R

W/BK

R

240V

60 Hz

SINGLE

PHASE

ATTACH

GROUND

WIRE

HERE

R

TRANSFORMER

120-240V / 24 V

BK

W/R

W/BK

ATTACH

GROUND

WIRE

HERE

WIRE TO IGN/120

FOR 120 VOLTS

WIRE TO IGN/240

FOR 240 VOLTS

ALTERNATE 120 V WIRING

H0236300-

BK

-

W

-

BR

-

Y

-

R

-

O

-

Y/BK -

W/BK -

W/R -

G/Y

-

Black

White

Brown

Yellow

Red

Orange

Yellow & Black

White & Black

White & Red

Green & Yellow

G

R

BK

G

G

(L1)

(L2)

BK

R

BK

R

G/Y

FS

IGNITER

FLAME SENSE ROD

FS

FLAME SENSOR

W

W

W

Figure 6. LD Connection/Schematic Wiring Diagram.

240V CONNECTION

SHOWN

MODEL LD WIRING DIAGRAM