Page 17

Legacy

™

Model LRZM Pool/Spa Heater Installation and Operation Manual

5.2

Check Valve Installation

The heater must be protected from back-siphon-

ing of water, which can result in dry starts. If there is

any chance of back-siphoning, provide a check valve

between the pool and the

fi

lter pump inlet.

When an automatic chemical feeder is installed

in the plumbing, it must be installed downstream of

the heater (see Section 5.7). A check valve must be

installed between the heater and the chemical feeder to

prevent back-siphoning of chemically saturated water

into the heater where it will damage the components.

5.3

Automatic Flow Control Valve

The inlet/outlet header of the Legacy comes

equipped with an automatic

fl

ow control valve. The

automatic

fl

ow control valve maintains the proper

fl

ow through the heater at rates up to approximately

125 Gallons Per Minute (GPM) (475 liters per minute

[LPM]). If the

fi

lter system

fl

ow rate is higher than

approximately 125 GPM (475 LPM), install a manual

bypass valve (see Figure 7), then perform a tempera-

ture rise test (see Section 7.6) and adjust the

fl

ow using

the bypass valve until the proper temperature rise is

obtained.

5.4

Reversible Water Connections

NOTE

Reversing the header requires a longer

syphon tube, order part number R0483601.

The Legacy heater is shipped with water connec-

tions on the right side, but can be modi

fi

ed in the

fi

eld

to provide left-side water connections. This proce-

dure involves removing the heat exchanger headers

and reinstalling them on opposite ends of the tube

assembly. Some of the heater wiring must be discon-

nected and re-routed, so this procedure must be done

only by a trained service technician. Heat exchanger

reversals are generally done before the installation of

power and water to the heater. If you need to reverse

the heat exchanger on a previously installed heater be

sure that all electrical power, the gas supply and water

supply have been turned off before starting the proce-

dure. These instructions have been written to include

the steps needed when reversing the water connec-

tions on an existing installation. If you are reversing

the headers on a new installation, some steps will be

ignored. Water connection reversal is illustrated in

Figures 8 and 9. Proceed as follows:

1.

For an existing installation, drain the heater by

removing the two drain plugs on the inlet/outlet

header and the drain plug on the return header.

2.

Remove the heater front panel (door).

3.

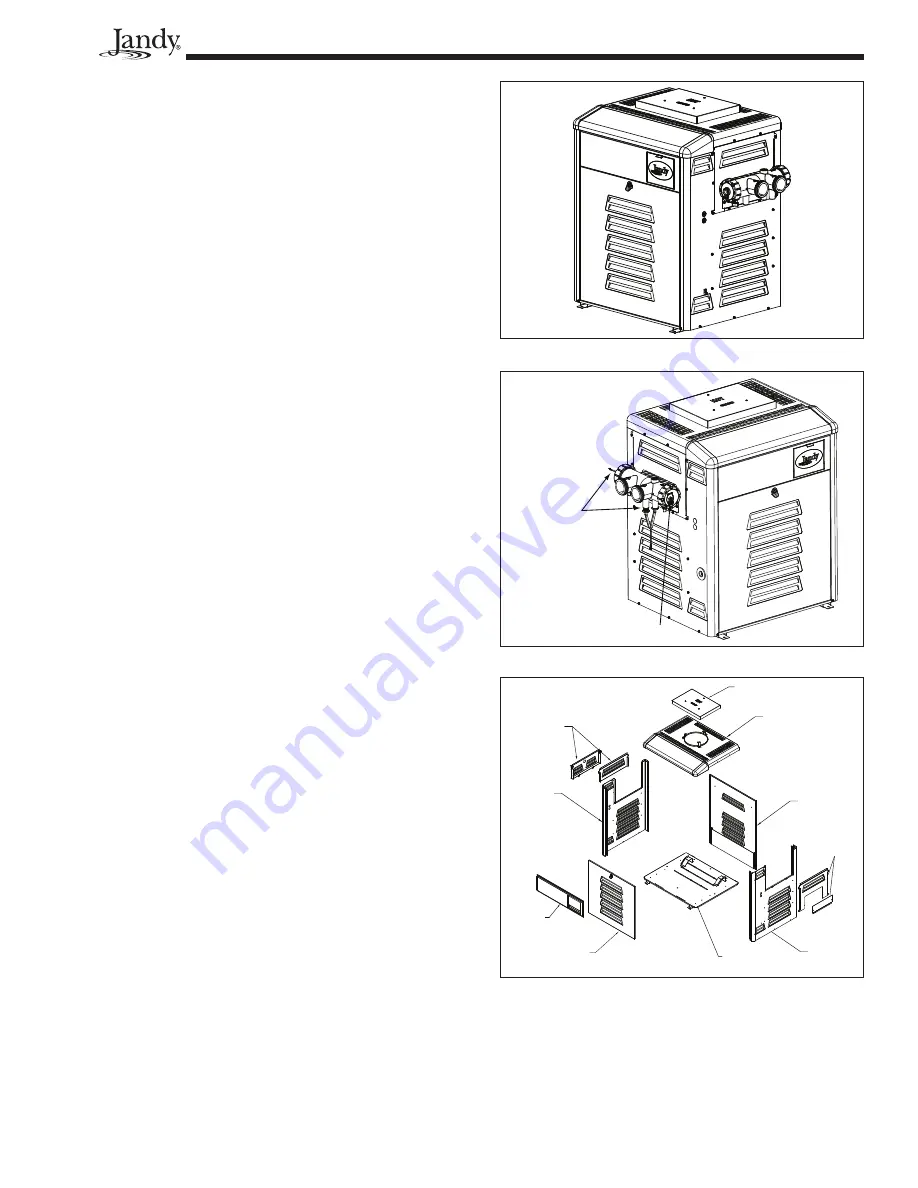

Remove the I/O header side cover plates, top and

bottom. See Figure 10.

4.

Remove the return header side cover plates, top

and bottom. See Figure 10.

NOTE: When reversal

is complete the water

temperature sensor

wires and the syphon

loop tube will exit the

inlet/outlet header at

the back of the heater

and the drain plugs are

facing down.

Bypass

Assembly

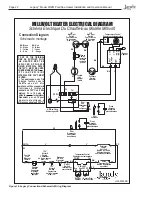

Figure 8. Water Connections as Shipped

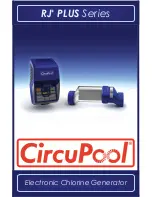

Figure 9. Water Connections Reversed

REAR PANEL

TOP PANEL

RIGHT SIDE PANEL

LEFT SIDE PANEL

RETURN HEADER SIDE

COVER PLATES

TOP AND BOTTOM

FRONT PANEL

(DOOR)

CONTROL PANEL

BASE

IN/OUT HEADER

SIDE COVER PLATES

TOP AND BOTTOM

VENT TOP

Figure 10. Legacy Panel Identi

fi

cation

Summary of Contents for Legacy LRZM

Page 2: ......