Page 34

Legacy

™

Model LRZM Pool/Spa Heater Installation and Operation Manual

2.

Temperature Control

- The Jandy Legacy

controller is an electronic control which senses

water temperature by means of a thermistor and

controls heater operation to bring the water to the

desired temperature. The desired temperature is

set by rotating a knob on the face of the control

panel. To achieve accurate water temperatures,

the pool/spa water must be monitored with an

accurate pool thermometer.

3.

Pilot/Pilot Ignition

- The Legacy heater relies

on a standing pilot to ignite the burners when the

temperature control calls for heat. When lit the

pilot receives a constant

fl

ow of gas from the gas

valve. If the pilot extinguishes, the gas valve is

automatically signalled to stop the

fl

ow of gas to

the pilot and the burners to prevent a gas build

up in the heater. Igniting the pilot is achieved by

means of a piezo spark igniter mounted on the

inner front panel of the controls compartment of

the heater.

4.

Pilot Generator (Thermopile) -

The pilot gener-

ator is a device, that when heated by the

fl

ame

of the pilot, generates a small electrical voltage

of approximately 750 millivolts. The voltage

is placed across the temperature controller and

safety circuit of the heater. If this current is

broken at any time, the gas valve is immediately

shut off and the heater stops

fi

ring. This voltage

is also used to activate the gas valve's pilot coil

which allows gas to

fl

ow to the pilot after the gas

valve knob is released.

5.

Limit Switches

- Two limit switches prevent

excessive water temperature - one within the heat

exchanger and one for water leaving the heater.

If either senses excessive temperature, burner

operation is interrupted.

6.

Water Pressure Switch

- This control senses

whether or not water is available to the heater

by measuring back pressure inside of the heat

exchanger. If the pool water pump fails or the

water

fi

lter is blocked, the pressure switch

prevents operation of the burner.

7.

Fusible Link

- This is a single-use switch which

detects abnormal temperature in the component

vestibule. It is a fusible link which is held to

the inner panel just above the burner tray by a

sheet metal bracket. Excessive temperature in

the component compartment, possibly due to a

blocked

fl

ue or

fl

ame roll-out, will cause the link

to fail. This opens the safety circuit which shuts

off the gas valve and shuts the heater down.

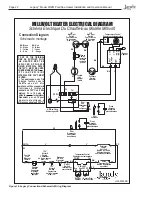

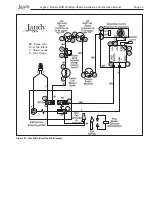

10.4 Electrical

Troubleshooting

This section describes procedures for check-

ing the pilot generator and control components of the

heater one at a time and in the order they appear in the

control circuit.

NOTE

Pump must be running during the

troubleshooting procedure.

These procedures require a voltmeter with a

minimum 0-1000 mVDC range. Figure 25 shows the

pilot generator and control circuits, and where to take

measurements. Location numbers and letters in circles

have been added, and will be referenced in the follow-

ing sections.

As stated at the beginning of this manual, some

of these procedures are hazardous. Only a quali

fi

ed

service technician should service the heater.

During the trouble shooting procedure, the

fi

lter

pump must be on, the pilot on the heater must be lit,

the ON/OFF switch on the heater must be in the ON

position and the control knob must be turned to the

maximum setting so that there is a call for heat. We

recommend turning the gas valve control knob to the

"PILOT" position to prevent the main burners from

fi

ring throughout the procedure. Before starting the

procedure, be sure that the pilot has been lit for at least

2 minutes and that the pilot generator (thermopile) is

positioned correctly within the

fl

ame of the pilot.

The pilot generator also operates the pilot coil of

the gas valve, allowing gas to

fl

ow to the pilot when

the gas valve knob is released from the pilot light-

ing position (see Section 7.3 "Lighting and Shutdown

Procedures"). If the pilot will not stay lit when the gas

valve knob is released, check the pilot generator output

as described in Section 10.4.2 and replace if necessary.

If the pilot generator output is suf

fi

cient, then check

the gas valve as outlined in Section 10.4.1.

10.4.1 Gas Valve

The gas valve consists of two (2) separate

internal operating valves. The main valve supplies

gas to the main burners for heater operation. The pilot

valve supplies gas to the pilot when the pilot generator

activates the pilot coil.

If the pilot will not stay lit after following the

lighting instructions in Section 7.3, check for the

following:

• Pilot generator output

• Correct type of gas supplied

• Correct gas supply pressure

• Air in the gas line

• Pilot coil wire connections clean and tight

If the pilot will not stay lit after checking the

items listed above, the pilot coil may be causing the

fault. Replace the gas valve.

Summary of Contents for Legacy LRZM

Page 2: ......