Page 39

Legacy

™

Model LRZM Pool/Spa Heater Installation and Operation Manual

Key

No.

Description

Model No.

Order

Part No.

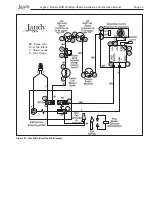

Pilot/Igniter System

1

Pilot, Main Burner Assembly, Natural

All

R0494700

1

Pilot, Main Burner Assembly, Propane

All

R0494800

2

Pilot Burner, Natural

All

R0492900

2

Pilot Burner, Propane

All

R0493000

3

Pilot Electrode

All

R0471400

4

Pilot Generator

All

R0471500

5

Ceramic Insulator

All

R0471600

6

Burner, Main w/ Pilot Bracket

All

R0471700

7

High Voltage Lead Assembly

All

R0493400

8

Pilot Tubing

All

R0037000

9

Piezo Lighter Assembly

All

R0355900

10

Mounting Bracket Assembly

All

R0471800

Main Gas Assembly

11

Burner Tray Assy, Natural

125-400

R0471101-05

11

Burner Tray Assy, Propane

125-400

R0471201-05

12

Burner Tray, Shelf Only

125-400

R0469101-05

13

Gas Valve, Natural

All

R0493100

13

Gas Valve, Propane

All

R0493200

14*

Ori

fi

ce Set, Natural Gas, 0-3K ft.

All

R0469200

14*

Ori

fi

ce Set, Natural Gas, 3-6K ft.

All

R0469300

14*

Ori

fi

ce Set, Natural Gas, 6-10K ft. (US only)

All

R0469400

14*

Ori

fi

ce Set, L.P. Gas, 0-5K ft.

All

R0469500

14*

Ori

fi

ce Set, L.P. Gas, 5-10K ft. (US only)

All

R0469600

15

Manifold Assy, Natural Gas, 0-3K ft.

125-400

R0496101-05

15

Manifold Assy, Natural Gas, 3-6K ft.

125-400

R0496201-05

15

Manifold Assy, Natural Gas, 6-10K ft. (US

only)

125-400

R0496301-05

15

Manifold Assy, L.P. Gas, 0-5K ft.

125-400

R0496401-05

15

Manifold Assy, L.P. Gas, 5-10K ft. (US only)

125-400

R0496501-05

16

Anti-Rotation Bracket

All

R0469700

17

Burner, Main

All

R0469800

18

Burner Manifold

125-400

R0469901-05

Electrical System

19

Temp Control/User Interface

All

R0471901

20

Temp Control/User Interface w/ Bezel

All

R0491700

21*

Wire Harness Set

All

R0472400

22

On-Off Switch

All

R0099800

23

Temperature Control Label

All

R0472100

24

Pool/Spa Control

All

R0472500

25

Temperature Sensor (Regular)

All

R0456500

26*

Temperature Sensor (Salt)

All

R0477300

27

Gasket, Temperature Control Bulb

All

R0456600

28

Thermostat Knob, Black

All

R0010700

29

Stop Plate, "Temp-Lok"

All

R0472200

30*

Temperature Control Gasket

All

R0472300

31

Temperature Control Plate Assembly

All

R0472001

32*

Stop Plate Screw

All

R0474600

33

Nut, Sensor Retainer

All

R0523900

34

Cap, Sensor & Pressure Switch w/ O-Ring

All

R0455400

35

Pressure Switch, 2 PSI

All

R0013200

36*

Pressure Switch, 1-10 PSI

All

R0015500

37

Water Pressure Switch Tubing

All

R0483600

37*

Water Pressure Switch Tubing, Long

All

R0483601

38

High-Limit Switch Assembly

All

R0457401

39

High Limit Set (130°F & 150°F)

All

R0457200

40

High-Limit Switch, 130°F

All

R0457300

41

High-Limit Switch, 150°F

All

R0023000

Key

No.

Description

Model No.

Order

Part No.

Electrical System (Continued)

42

Fusible Link Assembly

All

R0012200

43

Fusible Link Bracket

All

R0337200

44

Terminal Block

All

R0097800

Vent System

45

Top Enclosure

125-400

R0470301-05

46

Vent Cover

125-400

R0470401-05

47

Rainshield (Partition)

125-400

R0478201-05

48

Flue Collector Assembly

125-400

R0470501-05

49

Outdoor Vent Cap

125-400

R0491601-05

50

Indoor Draft Hood

125-400

R0499601-05

51

Adapter Plate

125-400

R0478301-05

52*

Clip

All

R0500200

Water System-Polymer

53

Inlet/Outlet Header Assy, Polymer

125-400

R0470800

54

Return Header Assy, Polymer

All

R0454200

55*

Header Hardware Set, Polymer

All

R0454500

56

Heat Exchanger Assembly, Complete, Copper 125-400

R0470606-10

56

Heat Exchanger Assembly, Complete, CuNi

125-400

R0500706-10

57

Heat Exchanger Drain Plugs (2), Polymer

All

R0446000

58

3" Coupling Nut Kit w/ O-ring

All

R0454000

59

Bypass Assembly, Polymer

125-400

R0453700

60

Bypass Spring, Adjustable, Polymer

All

R0453900

61

Tailpiece w/ Union Nut (Set of 2), Polymer

All

R0449000

Water System-Bronze

62

Heat Exchanger Assy, Complete, Copper

125-400

R0470706-10

62

Heat Exchanger Assy, Complete, CuNi

All

R0500806-10

63

Inlet/Outlet Header Assy, Bronze, 2"

125-400

R0476601-05

64

Return Header Assy, Bronze (includes set of

9 gaskets)

All

R0476700

65

Bypass Assembly, Bronze

125-400

R0476801-05

66

Bypass Spring, Bronze

125-400

R0476901-05

67

Bypass Gasket, Bronze

All

R0011400

68

Heat Exchange Hardware Kit, Bronze

All

R0477200

69

Temp Sensor Mounting Bracket, Bronze

All

R0477400

70

Water Pressure Switch Tubing, Bronze

All

R0477501

71

Flange & Gasket Kit, Bronze

All

R0461500

72

Flange Bolts, Bronze

All

R0477800

73

3/4 NPT Plug, Bronze

All

R0477900

74

Header, Drain Plug, Bronze

All

R0478000

Water System-All

75

Header Gasket Assembly (Set of 16)

All

R0454300

76*

Bypass Hardware, Gaskets

All

R0453800

77

Heat Exchanger Tube Assy, Copper

125-400

R0490101-05

78

Heat Exchanger Tube Assy, CuNi

125-400

R0490301-05

79*

Baf

fl

es, Heat Exchanger

125-250

R5000001-03

80

Plug, Sensor

All

R0456800

Firebox Components

81

Combustion Chamber Panels

125-400

R0494906-10

Jacket Components

82

Door with Latch

125-400

R0470901-05

83

Latch Assembly

All

R0334900

84

Grommet, Sealing, 2"

All

R0460300

85

Button Plug, 7/8"

All

R0491100

86

Rear Panel Assy

125-400

R0482301-05

87

Side Panel, Right

All

R0482400

88

In/Out Cover Panel, Top

All

R0482500

89

In/Out Cover Panel, Bottom

All

R0482600

90

Side Panel, Left

All

R0482700

11.2 Parts

List

Summary of Contents for Legacy LRZM

Page 2: ......