Page 26

7.

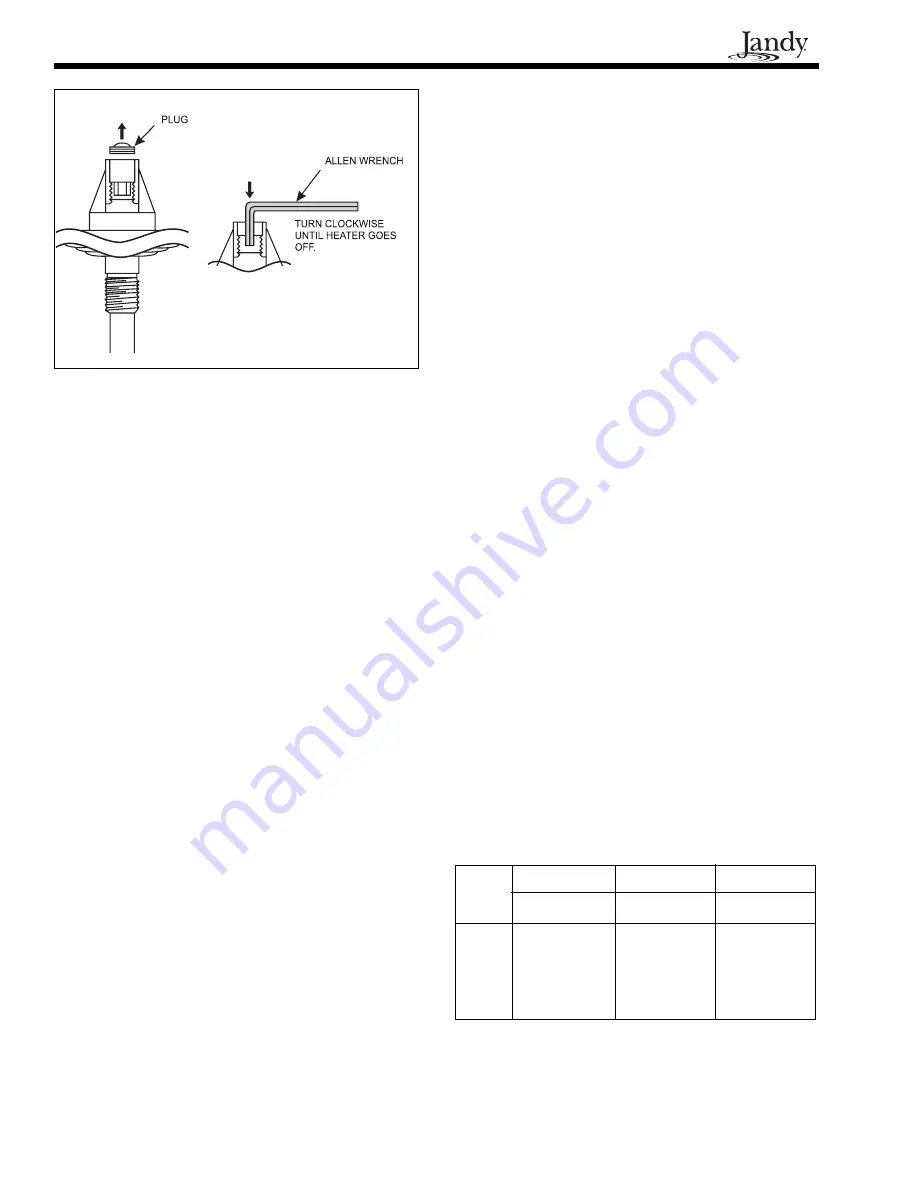

Slowly turn the pressure switch adjustment

screw

counterclockwise

one-quarter turn. The

heater should come back on.

8.

Check the adjustment. Press the SELECT key to

turn the heater 'OFF'. Turn off the power to the

heater at the breaker. Unplug the pump relay

from the power circuit board. Restore power to

the heater. Press the SELECT key to set the

heater to 'POOL'.

The heater must not come

on.

If the heater does start the firing sequence,

immediately press the SELECT key to turn the

heater off, disconnect power to the heater, plug

the pump relay into the power circuit board and

restore the power to the heater. Then repeat

Steps 6 and 7. Check the adjustment again.

When the adjustment has been checked and

verified, press the SELECT key to turn the

heater off, disconnect power to the heater, plug

the pump relay into the power circuit board and

restore the power to the heater.

9.

Return the pool temperature control to the

desired temperature. Repeatedly depress the

MODE key until the indicator at the top of the

display shows 'POOL SET'. Press the ENTER

key. Then use the UP and DOWN keys to set

the heater to the desired temperature. Press the

ENTER key again.

7.7. Temperature Rise

A temperature rise test confirms proper water

flow through the heater. The temperature rise is the

difference between the temperature of the pool or spa

water before and after heating, as measured in the

header. Perform the following temperature rise test

when the installation is complete:

1.

Make sure the pool filter is clean.

2.

Set the controller to 'OFF' by repeatedly depress-

ing the SELECTION key until the display shows

that the heater is 'OFF'.

Minimum

Minimum

Maximum

Size

GPM (LPM)

°F

(°C)

°F

(°C)

125

20

(76)

27

(15)

36

(20)

175

20

(76)

33

(19)

42

(24)

250

25

(95)

33

(19)

42

(24)

325

30

(114)

28

(16)

38

(21)

400

30

(114)

30

(17)

39

(22)

Table 7. Temperature Rise and Minimum Flow Rates

3.

If the filter pump is on, turn it off by pressing the

PUMP key and allow up to five minutes for the

pump to shut down.

4.

Turn off the power supply to the heater at the

circuit breaker panel.

5.

Remove the drain plug located on the inlet/outlet

header of the heater and replace it with a Pete's

plug (see Figure 14).

6.

Insert a pocket thermometer (see Figure 14)

through the Pete's plug into the header.

7.

Turn the circuit breaker on to supply the heater

with power.

8.

Turn the filter pump on and wait 3 minutes. The

heater remains off. This allows water from the

pool to reach the heater.

9.

Record the temperature indicated by the ther-

mometer (cold water).

10. Set the pool temperature control to the maximum

setting. Repeatedly depress the MODE key until

the indicator at the top of the display shows

'POOL SET'. Press the ENTER key. Then use

the UP key to set the temperature to 104°F

(40°C). Press the ENTER key again.

11. Set the controller to 'POOL' by repeatedly

depressing the SELECTION key until the display

shows that the heater is set to 'POOL'. The

heater should start.

12. Allow the heater to run for about 3 minutes.

Record the new temperature reading (heated

water).

13. Subtract the first temperature reading (cold

water) from the second temperature reading

(heated water). The difference between the two

readings is the

temperature rise

. The tempera-

ture rise should be within the range shown in

Table 7.

Figure 20. Pressure Switch Adjustment.

14. If the temperature rise is below the minimum

range indicated, two possibilities arise:

a. The supply gas volume is too low.

Summary of Contents for LJ

Page 45: ...Model LJ Pool and Spa Heater Page 43 NOTES...

Page 46: ...Page 44 NOTES...