LX and LT Low NOx Pool/Spa Heater

Page 37

The system operates with a balanced combina-

tion of natural and induced draft. Air and gas are

pulled into the burner venturis where they are mixed

and conveyed to the combustion chamber. The

combustion process produces heat and creates a

negative pressure or "draft" condition. A small

amount of secondary air is pulled into the chamber

through holes and openings provided for that purpose.

Hot combustion products pass through a highly

efficient heat exchanger, where water absorbs most of

the heat. Cooler products continue on and are pulled

into the combustion blower, which exhausts them and

stabilizes system flow. Exhaust is directly to the

outdoor air through a grill, or for indoor heaters,

through vent piping.

10.3 Special Service Issues - Premix

Combustion System

10.3.1 System Operation

Premix combustion systems are less tolerant of

fuel and air imbalance than lesser technologies. Fuel

gas properties, incorrect supply or manifold pressure or

draft problems affect their operation and reliability. If

fuel gas heat content is low, combustion is "lean" and

tends to be unstable. Flames may lift off the burner,

causing outage. If heat content is high, "rich" combus-

tion results, with low, hot flames that can overheat the

burners. Likewise, low gas supply or manifold pressure

results in lean, unstable combustion and high manifold

pressure results in a rich process and hot burners.

"Draft", the negative pressure in the combustion

chamber pulls air through the burners and the "draft"

holes beneath the burners. Air is also pulled in through

various cracks or openings at the edges of the com-

bustion chamber and burner assembly. It is important

to control draft by assuring that fit and sealing remain

in "factory" condition. Service operations involving

burner, heat exchanger or flue collector removal must

be conducted with this in mind.

10.3.2 Field Service and Adjustment

As with all gas-fired appliances, the first order of

business is to verify correct gas type, supply pressure

and manifold pressure, as specified on the heater

rating plate and in other sections of this manual. If the

fuel supply differs greatly from "average", it may be

necessary to replace gas orifices. Contact the Jandy

Technical Service Group at (707) 776-8200 for

assistance in that situation.

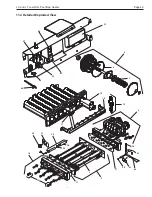

The most effective and convenient procedure for

evaluation of system operation is measurement of the

"flame signal". It can be measured at the pin connec-

tions on the ignition control next to the red LED lamp.

A two-pin wire harness, available from Jandy Techni-

cal support, and a microammeter with a zero to 10

microamp scale are ideal for reading the flame cur-

rent. If flame current is less than 0.7

µ

amps the

ignition control shuts down the system. Normally the

signal is five to seven

µ

amps. Figure 37 illustrates

flame signal measurement.

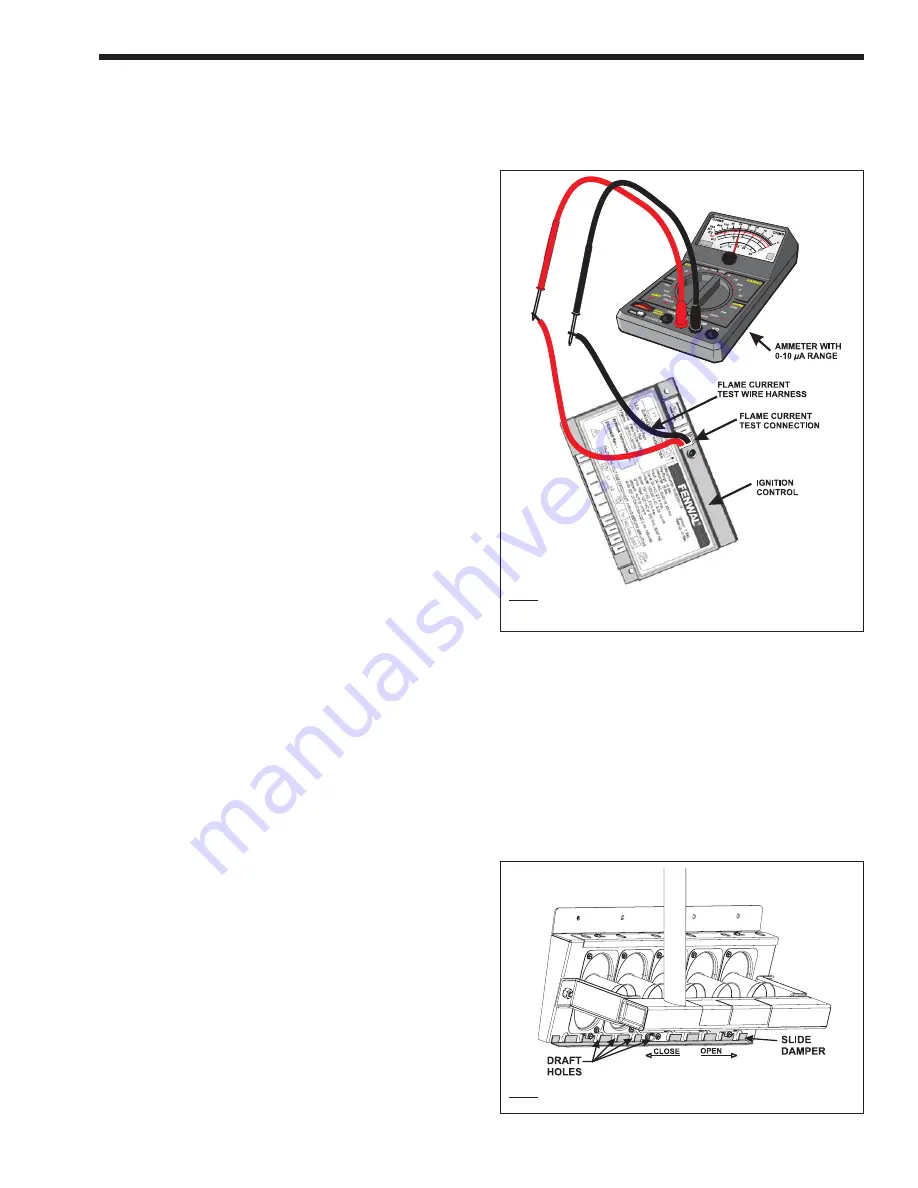

To accommodate construction or field factors

affecting draft, a slide damper is provided beneath the

burner inlets. Figure 38 illustrates this damper in its

factory-adjusted position for natural gas, which is half

open. Propane units are shipped with the damper in the

fully open position. If gas type and pressures are

correct, the damper can be used to adjust the system.

"Lean" flame-lifting conditions can be corrected by

opening the damper. This makes combustion chamber

pressure less negative. Likewise, "rich" hot flames can

be corrected by further closing the damper.

Figure 37. Measuring the Flame Current

NOTE: This illustration is only a representation of the measurement.

When the measurement is taken, the ignition control must be completely

connected to the heater and the heater must be running.

Figure 38. Slide Damper Draft Adjustment

NOTE: Natural gas burner tray shown with slide damper in factory

installed position.