Page 16

LXi

™

Pool/Spa Heater Installation and Operation Manual

Section 4. Gas Connections

4.1

Gas Supply and Piping

Review the following general instructions before

continuing the installation.

WARNING

The LXi pool and spa heaters are designed for use

with either natural gas or LP gas. Check the rating

plate on the inner panel to be sure that the heater is

designed to use the type of gas being supplied.

DO

NOT ATTEMPT TO CONVERT THIS HEATER FOR

USE WITH ANY OTHER TYPE OF FUEL.

AVERTISSEMENT

Les appareils de chauffage à faibles émissions

LXi pour piscines et cuves thermales sont conçus

pour être utilisés avec du gaz naturel ou du gaz de

pétrole liqué

fi

é (GPL). Véri

fi

ez l’information inscrite

sur la plaque signalétique du panneau intérieur pour

vous assurer que l’appareil est conçu pour le type

de gaz fourni.

NE PAS ESSAYER DE CONVERTIR

CET APPAREIL À UN AUTRE TYPE DE GAZ.

1.

Gas piping installation must be in accordance

with the latest edition of ANSI Z223.1 and all

local codes. In Canada, the installation must be in

accordance with CAN/CSA B149.1 and all local

codes that apply.

2.

Check the gas supply to be sure that it is the same

as the gas indicated on the heater's rating plate.

LXi heaters, as shipped from the factory, are set

to operate within the low altitude range. Follow

the instructions in

Section 10.4.3

to adjust the

heater for high altitude.

CAUTION

Permanent damage to the gas valve will occur if the

following procedures are not followed.

ATTENTION

Vous endommagerez la soupape de gaz si vous ne

respectez pas les procédures suivantes.

3. Use

the

fi

gures in Table 5 to size the gas inlet

piping from the gas meter to the heater. Check all

local codes for compliance before installing the

heater.

Table 5. Supply Gas Pipe Size Requirements*

Distance from Gas Meter

Heater

Size

0-50 feet

(0-15 m)

50-100 feet

(15-30 m)

100-200 feet

(30-60 m)

in.

mm

in.

mm

in.

mm

250

1

25

1-1/4

32

1-1/4

32

300

1-1/4

32

1-1/4

32

1-1/2

38

400

1-1/4

32

1-1/2

38

1-1/2

38

Notes:

*1. These numbers are for natural gas (0.65 Sp. Gr.) and

are based on 1/2 inch (3.45 kPa) water column pressure

drop. Check supply pressure with a manometer, and local

code requirements for variations.

For LP gas, reduce

pipe diameter by one size, but maintain a minimum

3/4" diameter.

2. Check supply pressure and local code requirements before

proceeding with work.

3. Pipe

fi

ttings must be considered when determining gas

pipe sizing.

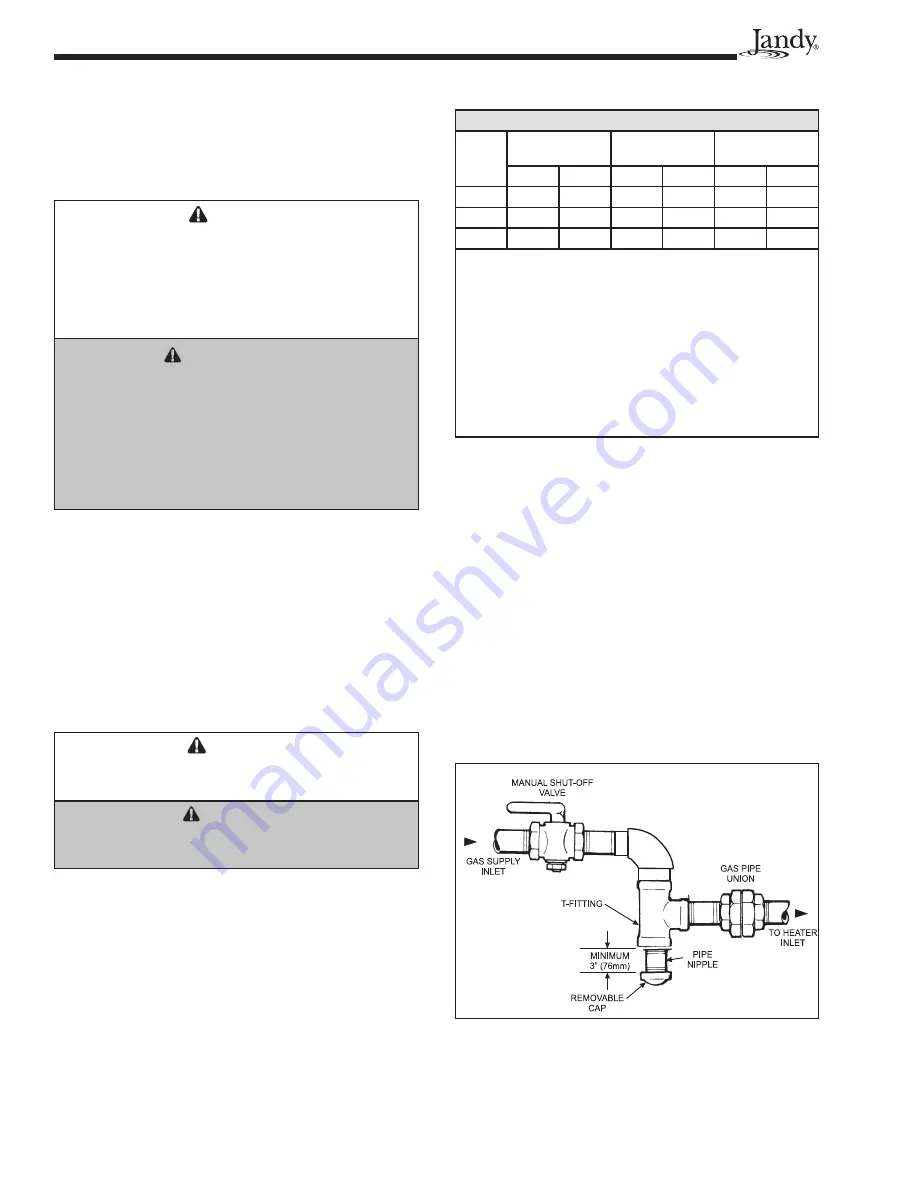

4.

Install a sediment trap (drip leg) ahead of the gas

controls. See Figure 9. Fit the trap with a thread-

ed cap which can be removed for cleaning.

5.

Install a manual gas shutoff valve for service

and safety. Do not use a restrictive gas cock.

DO NOT USE FLEXIBLE GAS PIPING, it will

restrict the gas

fl

ow to the heater.

6.

Disconnect the heater and its individual shutoff

valve from the gas supply system during pressure

testing of the system at pressures higher than 1/2

pounds per square inch (psi) (3.45 kilopascals

[kPa]). If the test pressure is equal to or less than

1/2 psi (3.45 kPa), close the manual shutoff valve

on the heater during the piping pressure test.

Figure 9. Proper Design for a Sediment Trap/Drip Leg

APPROVED

Summary of Contents for LXi

Page 2: ......