Page 18

SECTION 3.

Operating Instructions

Lighting and shutdown instructions are posted inside

the heater.

Do not attempt repairs on the gas control or

appliance. Tampering is dangerous and voids

all warranties.

LP GAS: To avoid possible injury, fire and

explosion, read and follow these precautions

and all instructions on this appliance before

starting the heater. LP (propane) gas is

heavier than air and will remain at ground level

if there is a leak. Before lighting, sniff at

ground level. If you smell gas, follow these

rules:

1.

DO NOT light matches. DO NOT turn

electric lights or switches on or off in

area. DO NOT use an electric fan to

remove the gas from area.

2.

Shut off gas at LP tank.

3.

Telephone gas company and fire

department for instructions. Give your

name, address and phone number.

If your LP tank runs out of fuel, turn off gas at the

appliance. After the tank is refilled, the appliance must be

restarted according to the instructions located on the inside

of the door.

3A. Start-Up Procedure

With any new pool or spa installation, run the filter

pump with the heater off long enough to completely clean

the water. This removes any installation residue from the

water. Clean the filter at the end of this operation before

starting the heater. Do not operate the heater unless the

pool is properly filled with water.

When raising the temperature of water in a cold

pool, remove all time clock settings. This lets the filter

system and heater operate continuously until the water

reaches the temperature setting on the thermostat. When

that happens, the heater will shut off automatically, but the

filter pump will keep running.

5.

Start the heater by setting the control panel to either

"Pool" or "Spa". Allow the heater to operate for five

minutes or more. Note and record the thermometer

reading. Subtract pool water temperature from this

reading. This difference is the temperature rise. Refer

to Table 8. If your measured temperature rise is

within the range designated for your heater, skip

steps 6 through 8.

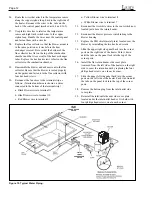

6.

Locate the bypass adjustment screw on the right-hand

side of the header (see figure 20). Loosen the nut so

that the screw can be adjusted. A slight water leak

past the nut may be expected. Turn the screw

counterclockwise to decrease the temperature rise,

and clockwise to increase the temperature rise as

needed to achieve the ranges in Table 8. After the

adjustment, tighten the nut so that no leaks occur.

7.

If the temperature rise is too low and cannot be raised

by means of the adjustment screw, the flow is in

excess of 125 GPM (7.9 l/s). An external bypass will

need to be installed, or if one already exists, open the

external bypass valve gradually until the temperature

range in Table 8 is achieved.

8.

If it was necessary to adjust the external bypass as

outlined in step 6, scribe a line on the bypass shaft

and case to mark the correct adjustment position.

Wire or remove the valve handle to prevent

tampering.

Note that temperature rise is somewhat less when a

heater is derated for installation at elevations significantly

above sea level. For high elevation installations, reduce the

numbers in Table 8 by 3% per 1000 feet above sea level.

Table 8. Water Temperature Rise and Flow Rates

(Measured at Input/Output Header)

Minimum

Maximum

Minimum System

Model Temp Rise, Temp Rise,

Flow

°F (C)

°F (C)

GPM (l/s)

250

24 (13)

28 (16)

30 (1.9)

400

36 (20)

40 (22)

30 (1.9)

In a system without external bypass, it may be

necessary to make changes. If temperature rise is too low,

a manual bypass must be installed. If temperature rise is

too high, there is inadequate flow, possibly requiring a

change to the piping system or a larger pump. Before

proceeding with either remedy, verify proper heater

operation. Low gas input results in low temperature rise

and vice-versa. A problem with the heater internal bypass

assembly also affects measured temperature rise.

WARNING

WARNING