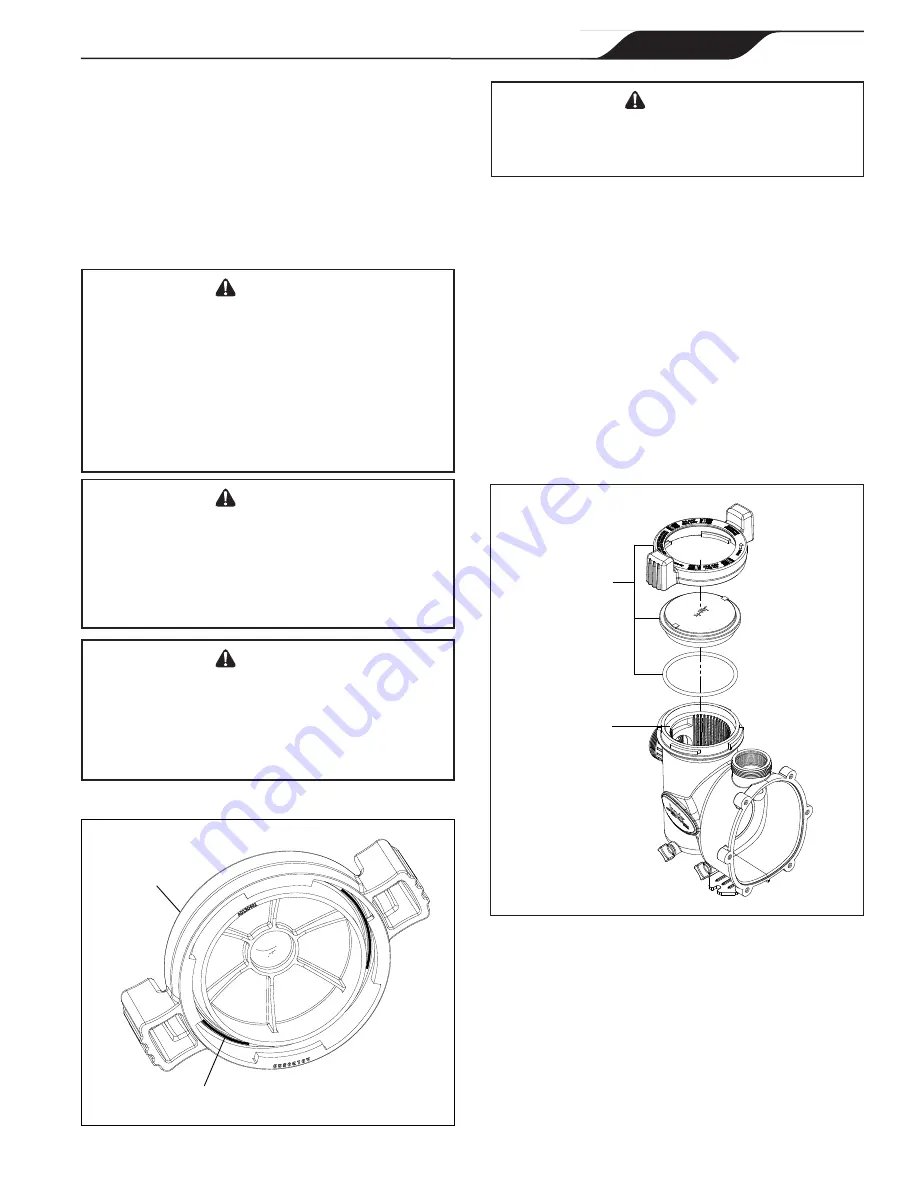

Lid with

Locking

Ring

and

Seal

Pump

Debris

Trap

Basket

(Inside

Pump)

Figure 7. Exploded View of Pump

Seal

Lid with

Locking

Ring

Figure 6. O-ring in Lid Assembly

3. Make sure all necessary isolation valves are closed

to prevent pool water from reaching the pump.

4. Following the markings on the locking ring, turn

the ring counter-clockwise until the ‘START’

markings align with the ports. See Figures 6 and 7.

5. Carefully remove the lid with locking ring.

3.5 Conduct Pressure Test

wARNING

When pressure testing a system with water, air

is often trapped in the system during the filling

process. This air will compress when the system

is pressurized. Should the system fail, this trapped

air can propel debris at a high speed and cause

injury. Every effort to remove trapped air must be

taken, including opening the bleed valve on the

filter and loosening the pump basket lid while filling

the pump.

wARNING

Trapped air in the system can cause the filter

lid to be blown off, which can result in death,

serious injury, or property damage. Be sure all

air is properly purged out of the system before

operating. DO NOT USE COMPRESSED AIR TO

PRESSURE TEST OR CHECK FOR LEAKS.

wARNING

Do not pressure test above 35 PSI. Pressure

testing must be done by a trained pool

professional. Circulation equipment that is not

tested properly might fail, which could result in

severe injury or property damage.

wARNING

When pressure testing the system with water, it is

very important to make sure that the pump basket

lid is completely secure.

1. Fill the system with water, using care to eliminate

trapped air.

2. Pressurize the system with water to no more than

35 PSI

.

3. Close the valve to trap pressurized water in the

system.

4. Observe the system for leaks and/or pressure

decay.

5. If there are lid leaks, repeat this procedure. For

technical support, call 800.822.7933.

Page 13

Jandy

®

FloPro™ Variable-Speed Pump Series VS-FHP

|

Installation and Operation Manual

ENGLISH