8. Tighten the screws lightly in a crossing “X”

pattern using a 9/16" wrench. Start with the inner

(middle) four (4), then the outer (top and bottom)

four (4) to draw the backplate to the body in an

even manner. Once all the screws are snug, torque

in the same order to 10 foot-pounds.

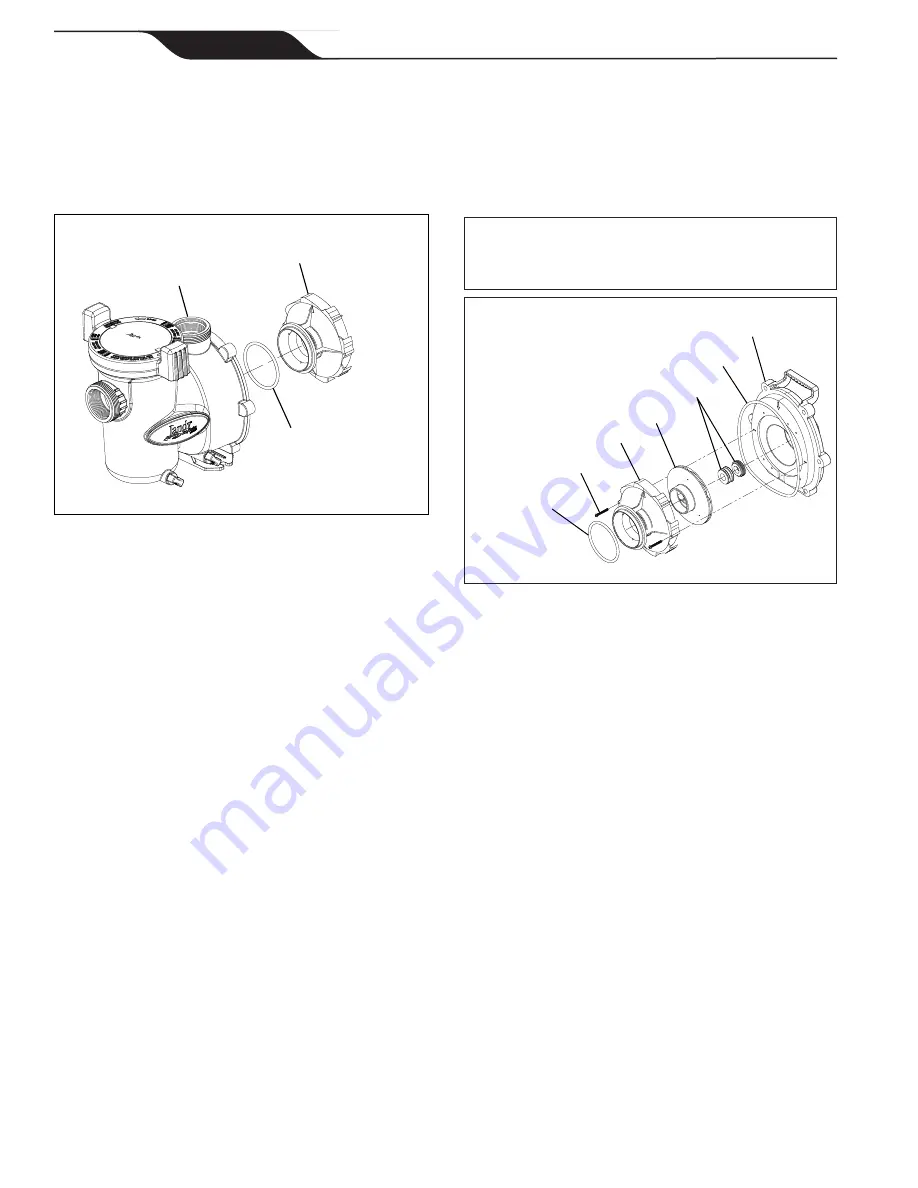

Figure 14. Backplate, Impeller, Diffuser, Mechanical

Seal Exploded View

Diffuser O-ring

Screws (2)

Diffuser

Impeller

Mechanical Seal

Backplate O-ring

Backplate

6.2.3 Mechanical Seal Replacement

NOTE

This is a two-part replacement process.

The

mechanical seal must be replaced as a set.

NOTE

Refer to Figure 14 for an illustration of the

location of the mechanical seal and impeller.

CAUTION

Do not damage the ceramic or carbon surfaces of the

seals. If the surfaces are damaged, leaks will occur.

1. To access the mechanical seal, see Section 6.2.2,

Impeller Removal and Replacement.

2. Remove the carbon face seal half from the motor

shaft (See Figure 14). This is a spring-loaded seal.

Grasp the portion of the seal closest to the impeller

body and pull the seal off, using a twisting motion.

3. Remove the motor from the backplate, following

the steps in Section 6.2.4, Motor Replacement.

4. Place the backplate o-ring side down and force the

ceramic seal out using a screwdriver or drift.

5. Turn the backplate o-ring side up and insert the

new ceramic seal side into the backplate. Use

great care to press the seal in squarely with your

fingers. The ceramic is easily damaged and must

be pressed in using only your fingers or soft tools.

Do not use any lubricant other than water or soapy

water.

6. Install the backplate by following the relevant

steps in Section 6.2.2.1, Impeller Reassembly.

7. Install the motor by following the steps in

Section 6.2.4, Motor Replacement.

Diffuser

Diffuser O-ring

Pump Body

Figure 13. Pump Body and Diffuser Exploded View

9. If the pump is located above the water level of the

pool, remove the lid and fill the basket with water

before starting the pump.

10. To help prevent an air leak into the system, remove

any debris around the lid seal seat.

11.

Hand-tighten

the lid to make an air tight seal.

Do not use any tools to tighten the lid.

12. Open the pressure release valve on the filter and

make sure it is clean and ready for operation.

13. Switch on the circuit breaker to the pump motor.

14. Turn on the pump and check the system for normal

operation.

15. Once all the air has left the filter, close the

pressure release valve.

Page 20

Jandy

®

FloPro™ Variable-Speed Pump Series VS-FHP

|

Installation and Operation Manual

ENGLISH