Page 11

ENGLISH

Jandy

®

Variable-Speed Pumps

|

Installation & Operation Manual

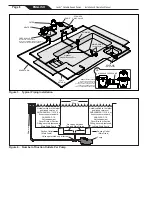

Base Configuration

Suction

Side

Height

Pump

Height

1. Pump without Base

7 3/4”

12 3/4”

2. Pump with Base

8 7/8"

13 7/8”

3. Pump with Base and

Spacers

9 1/8”

14 1/8”

4. Pump with Small + Large

Base

10 3/4”

15 3/4”

Table 2. Adjustable Base Dimensions (VS FloPro

Models Only)

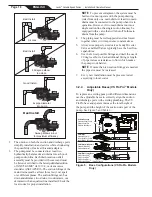

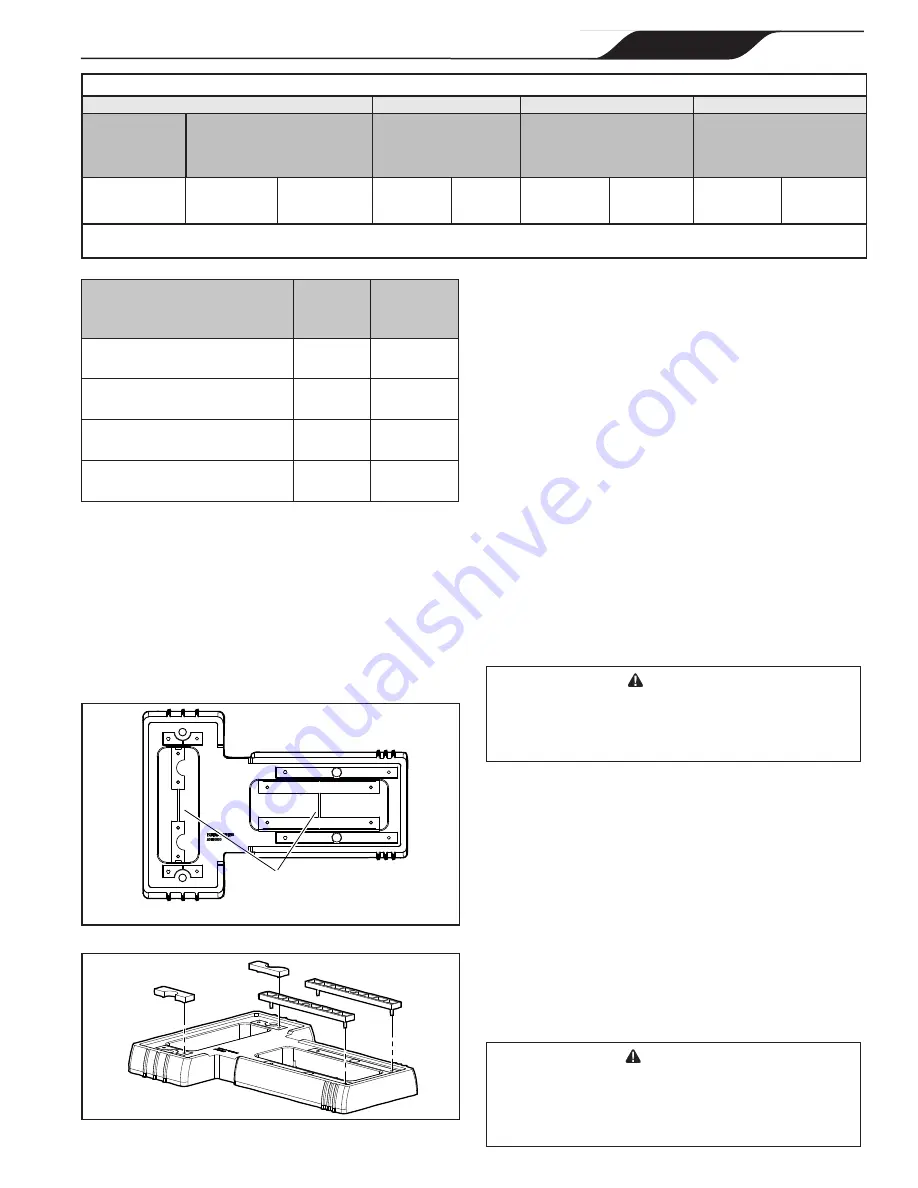

1.

Using a hand cutter tool, cut the plastic bars

connecting the top and bottom sets of spacers, as

shown in Figure 6.

2.

Push the two top spacers and two bottom spacers

out of the base.

3.

Align the pins in the four spacers with the holes in

the base. Snap the spacers into place (Fig. 7).

X

X

Cut

spacers

at

X

.

Figure 6. Cut Sets of Spacers Out of Base

Figure 7. Snap Spacers into Place

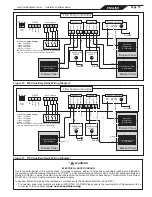

MINIMUM WIRE SIZE AND MINIMUM OVERCURRENT PROTECTION*

Distance from Sub-Panel

0-50 feet (15 meters)

50-100 feet (15-30 meters)

100-200 feet (30-60 meters)

Pump Model

Inverse - Time Circuit Breaker or

Branch Fuse AMPs

Class: CC, G, H, J, K, RK, or T

Voltage

Voltage

Voltage

230 VAC

115 VAC

230 VAC

115 VAC

230 VAC

115 VAC

230 VAC

115 VAC

VSFHP185DV2A

VSFHP270DV2A

VSPHP270DV2A

15A

20A

14 AWG

(2.1mm

2

)

12 AWG

(3.3mm

2

)

12 AWG

(3.3mm

2

)

10 AWG

(5.3mm

2

)

10 AWG

(5.3mm

2

)

10 AWG

(5.3mm

2

)

*Assumes three (3) copper conductors in a buried conduit and 3% maximum voltage loss in branch circuit. All National Electrical Code

®

(NEC

®

) and

local codes must be followed. Table shows minimum wire size and branch fuse recommendations for a typical installation per NEC.

3.3 Electrical Installation

3.3.1

Voltage Checks

The correct voltage, as specified on the pump data plate,

is necessary for proper performance and long motor

life. Incorrect voltage will decrease the pump’s ability to

perform and could cause overheating, reduce the motor life,

and result in higher electric bills.

It is the responsibility of the electrical installer to provide

data plate operating voltage to the pump by ensuring

proper circuit sizes and wire sizes for this specific

application.

The National Electrical Code

®

(NEC

®

, NFPA-70

®

)

requires all pool pump circuits be protected with a

Ground Fault Interrupter (GFCI). Therefore, it is also

the responsibility of the electrical installer to ensure that

the pump circuit is in compliance with this and all other

applicable requirements of the National Electrical Code

(NEC) and any other applicable installation codes.

CAUTION

Failure to provide data plate voltage (+/- 10%) during

operation will cause the motor to overheat and void

the warranty.

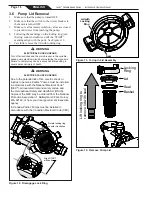

3.3.2

Bonding and Grounding

In addition to being properly grounded as described in

the

Electrical Wiring

section, and in accordance with

the requirements of the National Electrical Code (NEC),

or in Canada the Canadian Electrical Code (CEC),

the pump motor must be bonded to all metal parts of

the swimming pool, spa or hot tub structure and to all

electrical components and equipment associated with

the pool/spa water circulation system.The bonding must

be accomplished by using a solid copper conductor, No.

8 AWG or larger. In Canada No. 6 AWG or larger must

be used. Bond the motor using the external bonding lug

provided on the motor frame. See Figure 8.

WARNING

Always disconnect the power source before working

on a motor or its connected load.