Page 19

ENGLISH

Jandy

®

Variable-Speed Pumps

|

Installation & Operation Manual

Section 6. Troubleshooting and Repair

Zodiac

strongly recommends that you call a qualified service technician to perform any repairs on the filter/

pump system. To locate a qualified technician, check your local yellow pages or visit

ZodiacPoolSystem.com or

ZodiacPoolSystem.ca

and click on “Dealer Locator.”

Symptom

Possible Cause/Solution

Motor won't start or the

controller does not detect

the motor

No power to the motor. Have a certified professional check the voltage on the main

power terminal with the breaker on. The voltage must be within 10% of the motor

rating plate voltage.

The motor experienced an error. Power cycle the motor. If the motor has experienced

an error, a fault code may appear on the controller. In order to clear the error, turn off

the main breaker connected to the motor.

Wait at least 5 minutes

before returning

power to the motor. The voltage in the capacitors must be completely drained for a

proper power cycle.

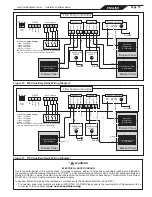

Improper low voltage wiring. The RS-485 connection must be secure with no broken

wires. Inspect the low voltage wiring for signs of corrosion. If necessary cut the wires

off and strip new leads. Make sure there are not any broken pieces of wire inside the

RS-485 connector.

Broken low voltage wiring. The wire may have breaks somewhere between the motor

and the controller. With all power off, take a multimeter and set it to Ohms/Continuity.

Check continuity of each of the low voltage lines from the motor side to the controller

side. Replace the RS-485 wires completely if necessary.

Improper low voltage wiring. Check the wiring of the RS-485 connector. Wire colors

for pins 1-4 should be Red, Black, Yellow, Green.

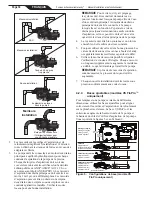

Test the drive with the RS-485 jumper method. Using small sections of 22 AWG wire,

jump pins 1 to 3 and 2 to 4. These wires can be made by cutting off a section of the

RS-485 wires. Re-install the connector and attach the access cover. Apply power to

the motor. The motor should spin at 2600 RPM indefintely. If the motor works, there

is a problem with the RS-485 line or with the controller. Contact Zodiac Technical

Support at 800.822.7933

DIP switches in the wrong configuration. The variable speed drive has two DIP

switches; 3 and 4. These must both be in the OFF position for Pump 01. This is

the configuration for all controllers that are not automation and the first pump for

automation. If more than one variable speed pump is being controlled with an

automation system, they must be in the proper configuration. Refer to the DIP switch

section of the manual to configure the other motors.

Check the schedule. The motor will only turn on during programmed times set in the

controller. Verify that the motor is scheduled to turn on at that time.

If the motor still has problems starting or continues to show faults, contact Zodiac

Technical Support at 800.822.7933

Motor starts but shuts off

soon after

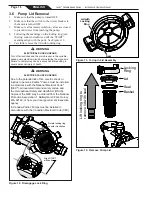

Debris may be stuck between the impeller and the diffuser. This will prevent the drive

shaft from spinning and will cause the motor to experience an error. Have a certified

professional check to see if the drive shaft is seized with all power off. A quick test

can be inserting a 5/16" allen wrench through the back of the fan housing and into the

drive shaft. Manually spin the drive shaft to check if it is seized. If large amounts of

debris are found, check your strainer basket for breaks. Replace the strainer basket if

necessary.

If the motor still has problems starting, contact Zodiac Technical Support at

800.822.7933