Busbar tap-off unit

www.janitza.de

52

10. Product description

10.1 Product description and application

areas

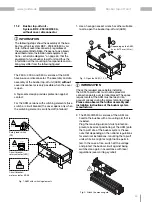

The busbar tap-off unit (AKM tap-off unit with

measurement technology) is used for the analysis

of energy efficiency in busbar trunking systems of

the type BD2. The BD2 busbar trunking system is

used for power transmission and distribution with

communication capability in office buildings and

industrial plants.

This supplementary user manual for the busbar

tap-off unit assumes that a BD2 busbar system is

already installed. Variants for other busbar sys-

tems must be evaluated in each individual case.

The implementation depends on technical and

economic boundary conditions.

The busbar tap-off unit for the BD2 busbar trunk-

ing system offers maximum safety through tested

low-voltage switchgear combinations according to

IEC 60439-1 / -21.

The high short-circuit resistance and low fire load

due to the sheet steel housing increase safety for

people and buildings.

In contrast to conventional cable installation,

where electricity can only be tapped at fixed

points, the ready-dimensioned busbar tap-off units

can be used flexibly and varied on the busbar

trunking systems (BD2). The installation is carried

out without any intervention in the connected

consumer (e.g. machine) and the associated loss

of warranty.

The AKM busbar tap-off unit

·is a ready dimensioned system for the con-

nection and energy monitoring of an electrical

consumer (e.g. a machine).

·performs a detailed energy efficiency analysis at

the machine level.

·is a ready dimensioned system which monitors

electrical parameters, such as currents, voltages,

power, power quality, etc. via the built-in mea-

surement device and the associated network

analysis

·can monitor the enclosure temperature and indi-

rectly the entire busbar system.

Various options and design variants of the bus-

bar tap-off unit allow adaptation to the respective

measurement task. This includes, for example, an

extended RCM measurement and the recording of

additional consumption values via pulse inputs.

INFORMATION

Please note!

The size of the busbar tap-off unit depends on the

variants (see „Technical data“ on page 72)!

The feed of the 125 A version of the busbar tap-

off unit is equipped with a cover disconnector,

which disconnects the tap-off unit from the live

busbar system when the cover is opened. This

allows shockproof working on the installed tap-

off unit.

With all other versions of the busbar tap-off

unit, there is no disconnection when the cover

is opened! In this case, a finger-safe design

provides protection against contact.