11

c

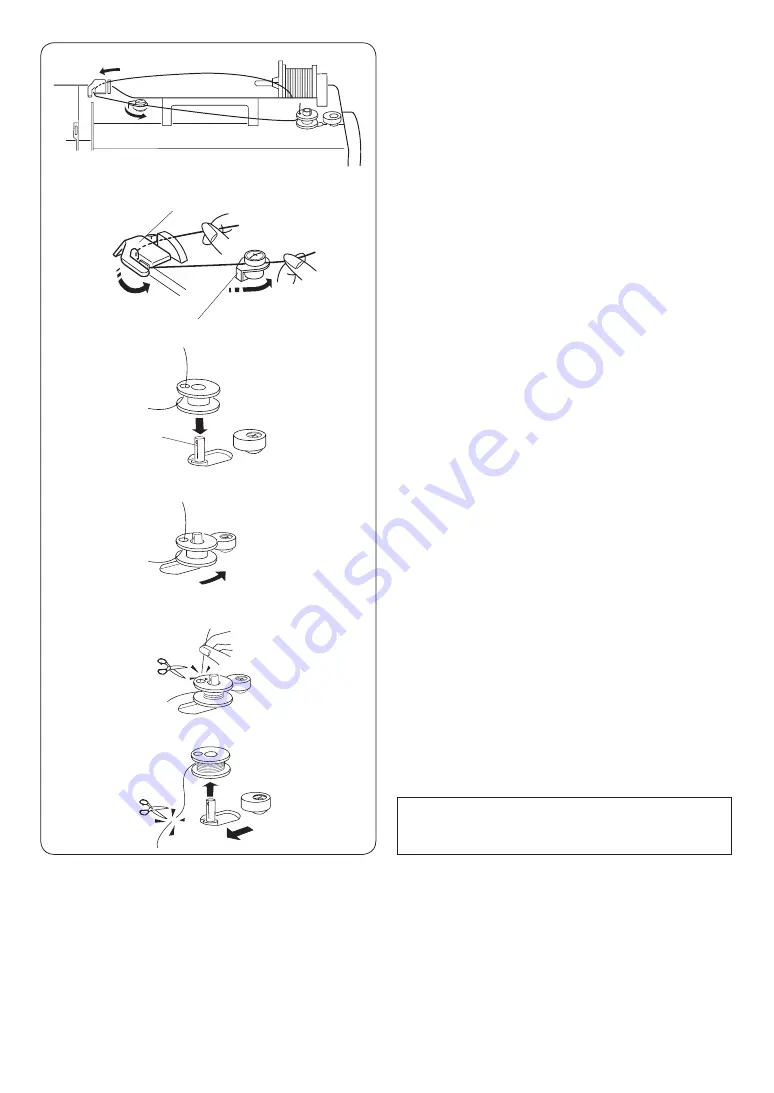

Push the bobbin winder spindle to the right.

v

Hold the free end of the thread in your hand

and start the machine.

Stop the machine when the bobbin has been

wound a few layers, and cut the thread close

to the bobbin.

b

Start the machine again. When the bobbin is

fully wound, it will stop automatically.

Stop the machine and return the bobbin winder

spindle to its original position by

moving it to the left, and cut the thread with a

pair of scissors. Remove the bobbin from the

bobbin winder spindle.

NOTE:

The machine will not sew until the spindle has

been returned to the left.

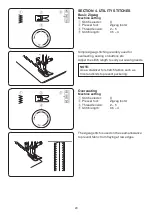

Winding the bobbin

z

Hold the thread with both hands and guide

the thread from back to front under the thread

guide.

q

Thread guide

Guide the thread into the bobbin winder

thread guide as illustrated.

w

Bobbin winder thread guide

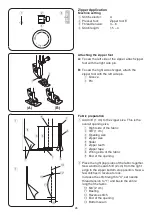

x

Pass the thread through the hole in the

bobbin from the inside to the outside.

Put the bobbin on the bobbin winder spindle.

Hold top of the bobbin winder spindle and

rotate the bobbin until it clicks into place.

e

Bobbin winder spindle

q

z

x

v

w

e

c

b