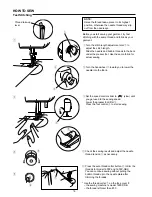

2

#5

#6

q

w

e

r

t

y

u

i

o

!0

!2

!3

!4

!5

!6

!7

!8

!9

@0

!1

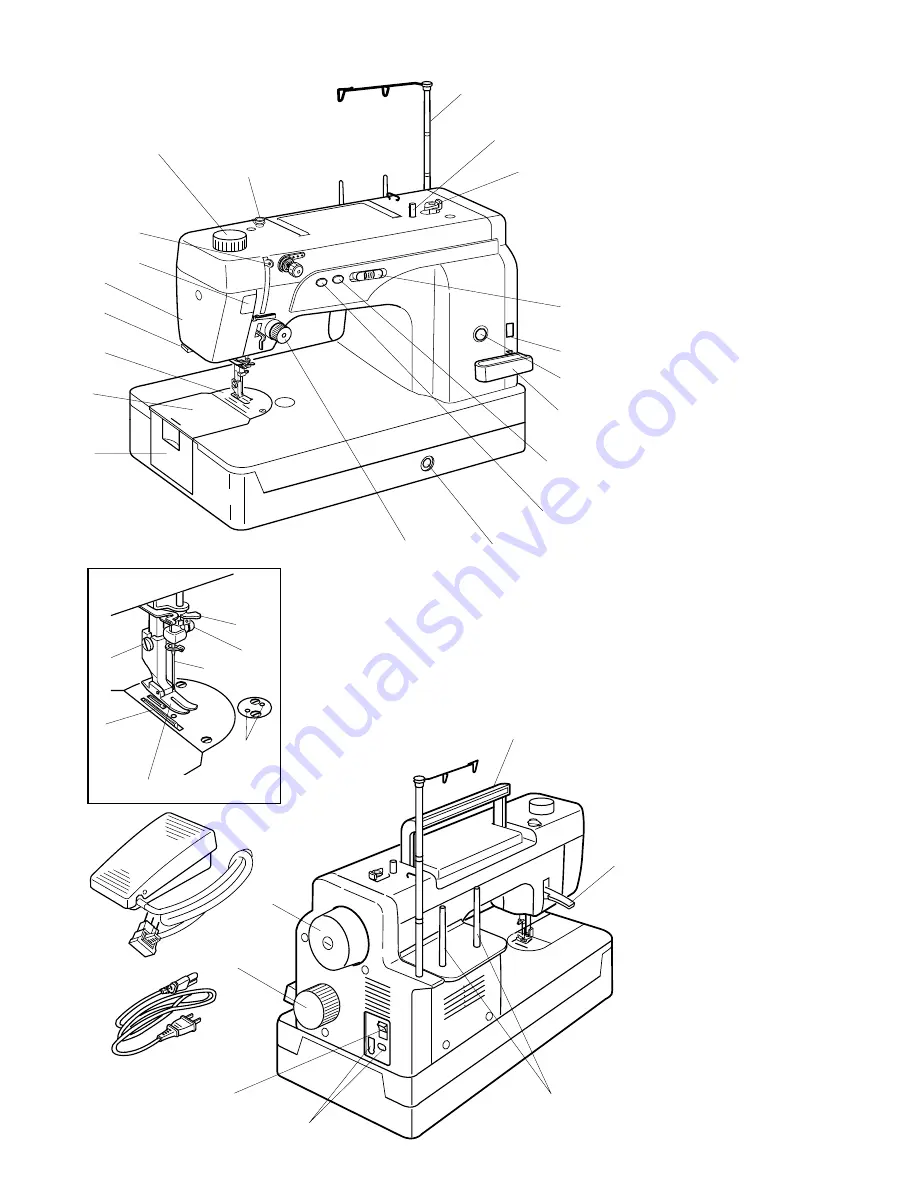

Name of Parts

q

Foot pressure dial

w

Thread guide

e

Retractable thread guide

r

Bobbin winder spindle

t

Bobbin winder stopper

y

Speed control slider

u

Stitch length display

i

* Thread cutter button

o

Reverse stitch lever

!0

Bobbin winding button

!1

Up/Down needle button

!2

Knee lifter socket

!3

Thread tension dial

!4

Hook cover

!5

Hook cover plate

!6

Needle plate

!7

Thread cutter

!8

Face cover

!9

Foot pressure indicator

@0

Thread take-up lever

@1

** Needle threader

@2

Needle clamp screw

@3

Needle

@4

Screw holes for attachments

@5

Presser foot

@6

Feed dog

@7

Setscrew

@8

Carrying handle

@9

Presser foot lifter

#0

Spool pins

#1

Machine sockets

#2

Power switch

#3

Stitch length adjustment dial

#4

Handwheel

#5

Foot control

#6

Power supply cord

@1

@2

@4

@5

@6

@3

@7

@8

@9

#0

#1

#2

#3

#4

KNOW YOUR MACHINE

* Model 1600P and 1600-DBX only

** Model 1600P only

Summary of Contents for 1600P series

Page 1: ......