25

NOTES:

• To sew the buttonholes 25 to 26, follow the same

procedure as Square BH (See page 26 to 27.).

• The size of a buttonhole is automatically set by placing

a button in the rear of automatic buttonhole foot R.

• The button holder of the foot takes a button size of up

to 1

˝

(2.5 cm) in diameter.

• It is sometimes necessary to change buttonhole size

to match certain heavy or specific materials and

threads.

• Make a test buttonhole on an extra piece of the fabric

to check your setting.

• Place the button on the fabric and mark the top and

button to determine the position of the buttonhole on

the fabric.

• Use interfacing on stretch fabrics.

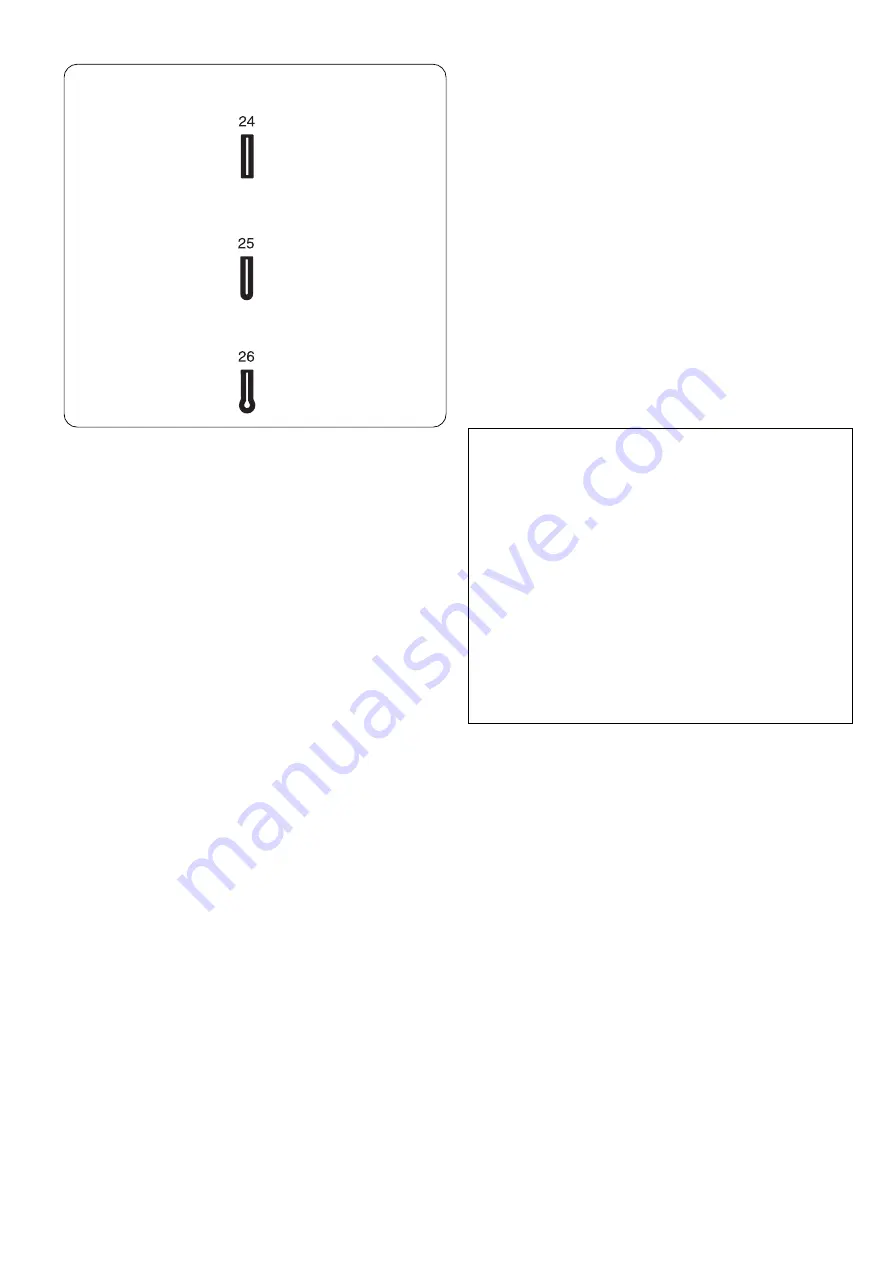

Various Kinds of Buttonholes and Their Uses

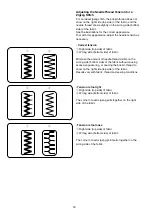

q

Square Buttonhole

This square buttonhole is widely used on medium to

heavy fabrics. The buttonhole size is automatically

determined by placing a button in the foot.

q

w

e

w

Round-end Buttonhole

This buttonhole is used on fine to medium weight

fabrics, especially for blouses and children’s clothes.

e

Keyhole Buttonhole

The keyhole buttonhole is widely used on medium to

heavy fabrics. It is also suitable for larger and thicker

buttons.

Summary of Contents for 2030DC-T

Page 1: ...INSTRUCTION BOOK...

Page 44: ...808 800 202 t EN...