4

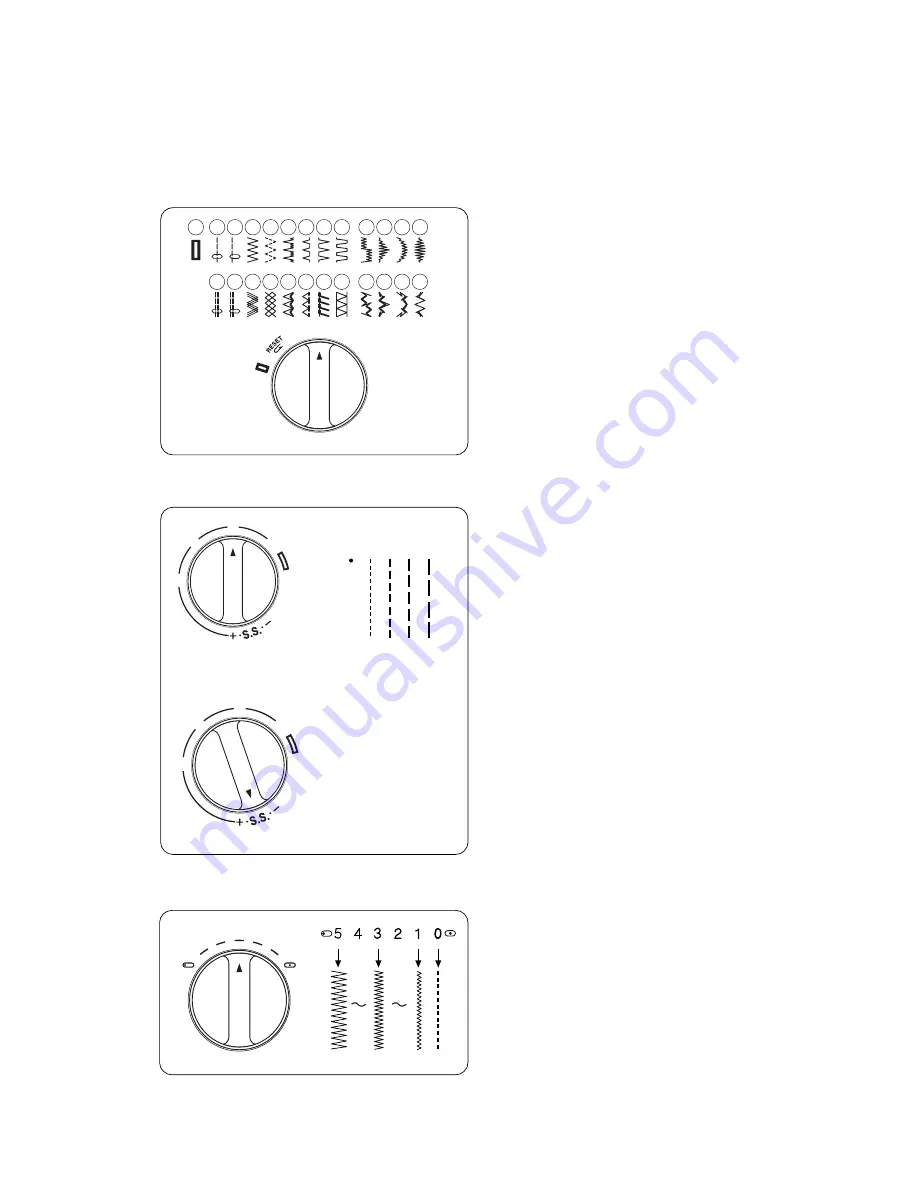

STITCH SELECTOR / STITCH LENGTH /

STITCH WIDTH CONTROLS

0 1 2 3 4

A

C

D

E

F

G

H

I

J

K

L

2

1

0

4

3

2

1

0

4

3

3

4

5

2

1

0

A

C

D

E

F

G

H

I

J

K

L

G

H

I

J

K

L

A

A

A

C

D

E

F

BH

STITCH SELECTOR

RAISE THE NEEDLE AND TURN THE STITCH

SELECTOR DIAL TO SET THE ARROW MARK

TO THE DESIRED PATTERN.

2049: A to L

2041: A to H

2018: A to G (No stretch patterns)

STITCH LENGTH (2049, 2041)

STITCH WIDTH (2049, 2041)

TURN THE STITCH WIDTH DIAL TO SET THE

ARROW MARK TO THE DESIRED WIDTH.

TURN THE STITCH LENGTH DIAL TO SET

THE ARROW MARK TO THE DESIRED

LENGTH.

SET THE ARROW MARK TO "S.S."WHEN

SELECTING STRETCH PATTERNS.