AAASewing.com

32

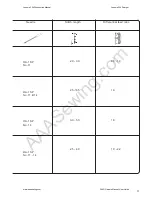

Stitch

Length

Differential

Feed Ratio

Needle Plate

Setting Knob

Needle

Needle

Thread

Upper and

Lower Looper

Threads

Fabric

Standard

Setting of

Tension

Dials

Correct

Thread

Tension

(R)

(1.0)

(R)

(3 ~ 4)

(1.0)

(R)

(R)

(1.0)

(R)

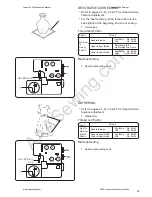

Needle thread

tension (L)

8

3

4

5

6 7

9

0

1

2

8

3

4

5

6

7

9

0

1

2

8

3

4

5

6 7

9

0

1

2

8

3

4

5

6

7

9

0

1

2

Needle thread

tension (R)

Upper looper

thread tension

Lower looper

thread tension

Needle thread

tension (L)

Needle thread

tension (R)

Upper looper

thread tension

Lower looper

thread tension

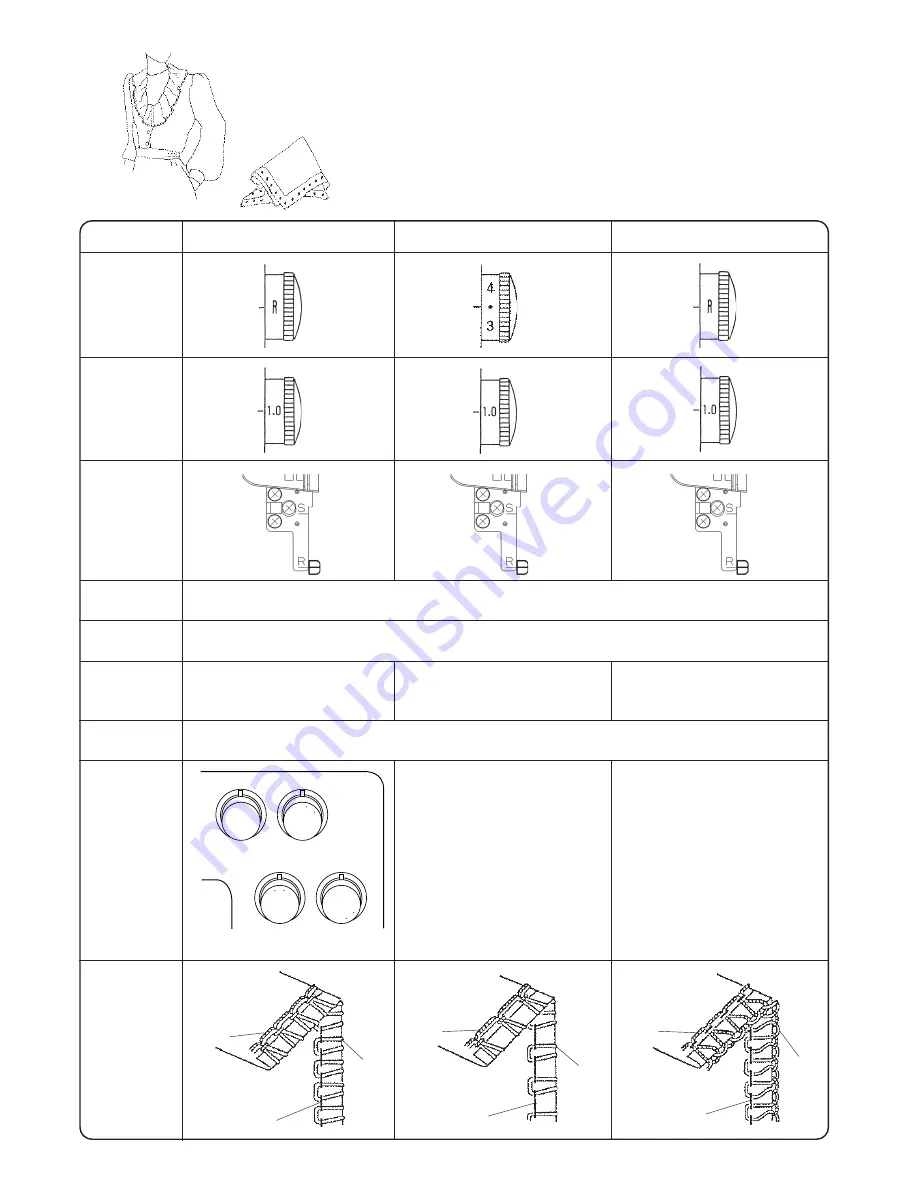

Wrong side

of fabric

Lower looper

thread

Upper

looper

thread

Right side

of fabric

Needle thread

Wrong side

of fabric

Lower looper

thread

Upper

looper

thread

Right side

of fabric

Needle thread

Needle thread

tension (L)

Needle thread

tension (R)

Upper looper

thread tension

Lower looper

thread tension

Wrong side

of fabric

Lower looper

thread

Upper

looper

thread

Right side

of fabric

Needle thread

Using the needle on the right: HA-1 SP No. 11

Synthetic: No. 80 ~ 100

Synthetic : No. 60 ~ 100

Silk : No. 50 ~ 100

Lightweight fabric such as Organdy, Crepe de chine, Lawn and Georgette

Woolly nylon,

Woolly polyester

Synthetic: No. 80 ~ 100

Woolly nylon,

Woolly polyester

Synthetic: No. 80 ~ 100

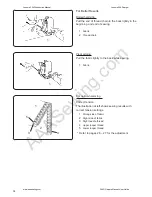

ROLLED HEMMING, PICOT EDGING AND NARROW HEMMING

Machine Setting and Thread, Fabric and Range of

the Tension Dial

The setting of tension dials may vary depending on the type

and thickness of fabric and thread being sewn.

Rolled Hemming

Picot Edging

Narrow Hemming

Janome 204D Instruction Manual

Janome 204D serger

www.aaasewing.com

204D Owners Manual/ User Guide