AAASewing.com

40

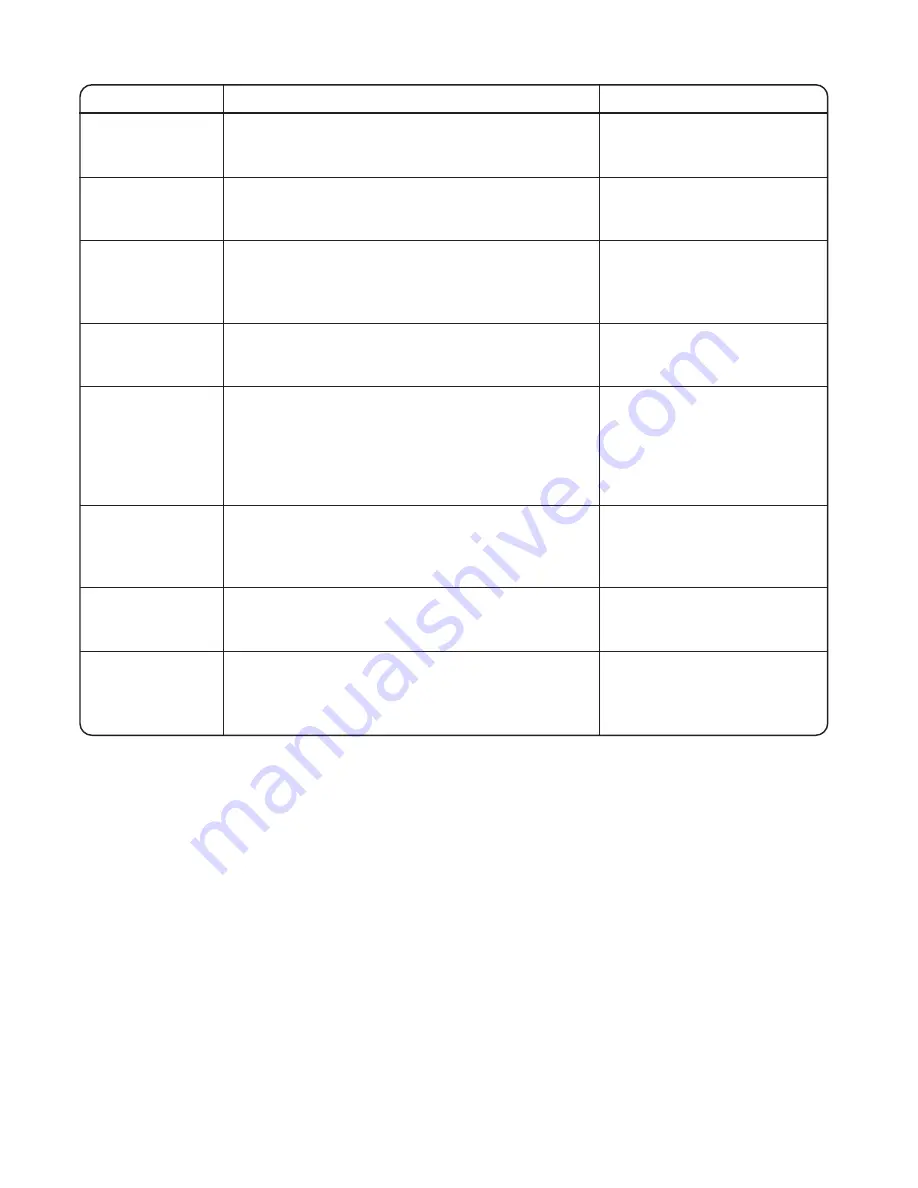

Troubleshooting

Condition

The fabric is not

being fed

smoothly.

The needle

breaks.

The thread

breaks.

Skipped stitches

The seam is not

sewn neatly.

Seam

puckering.

The machine

does

not operate.

The fabric is not

cut neatly.

Cause

1. The feed dog is packed with lint.

2. The presser foot has been raised.

1. The needle is incorrectly inserted.

2. The needle is bent or blunt.

3. The fabric is forcedly pulled.

1. The machine is not correctly threaded.

2. The needle or looper thread tension is too tight.

3. The needle is incorrectly inserted.

4. The needle is bent or blunt.

1. The needle is bent or blunt.

2. The machine is not correctly threaded.

3. The needle is incorrectly inserted.

1. The needle and/or looper thread tensions are

not correctly adjusted.

2. The machine is not correctly threaded.

3. The needle and/or the thread are not suitable

for the fabric being sewn.

4. The thread is not between the tension discs.

1. The needle or looper thread tension is too tight.

2. The machine is not correctly threaded.

3. The differential feed dial is not correctly

adjusted.

1. The machine has not been plugged in firmly.

2. The power switch is turned off.

1. The position of the upper knife is not adjusted

properly.

2. The upper knife is dull.

Reference

See page 38.

Lower the presser foot.

See page 8.

See page 8.

Pull the fabric lightly.

See pages 14 ~ 23 and 28.

See pages 26 ~ 27 and 29, 33.

See page 8.

See page 8.

See page 8.

See pages 14 ~ 23 and 28.

See page 8.

See pages 26 ~ 27 and 29, 33.

See pages 14 ~ 23 and 28.

See pages 30 ~ 32, 35 and 36.

See pages 16, 19, 21 and 23.

See pages 26 ~ 27 and 29, 33.

See pages 14 ~ 23 and 28.

See page 10.

See page 5.

See page 5.

See page 37.

Replace the upper knife.

(See page 37.)

Janome 204D Instruction Manual

Janome 204D serger

www.aaasewing.com

204D Owners Manual/ User Guide